Roll To Roll Mark-Tracking Printing Machine Description

Roll To Roll Mark-Tracking Screen Printing Press/Roll To Roll Mark-Tracking Screen Printer/Roll To Roll Mark-Tracking Screen Printing Equippment

Features:

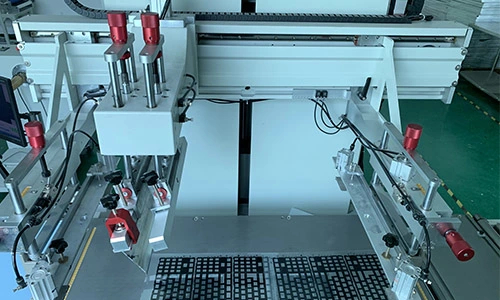

1. The printing seat adopts 4-column precise linear guide rail, with high repeatable positioning accuracy, strong stability and durability.

2. With off-screen function, printing a large area of background color and printing glue, to prevent the sticky screen.

3. With anti-drip ink function, prevent color difference between ink with ink, to achieve high quality printing.

4. Optional with automatic punching function, can easily realize double-sided printing.

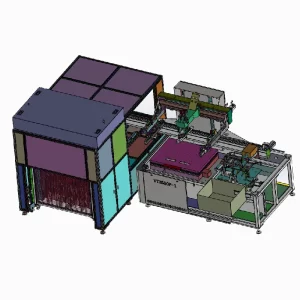

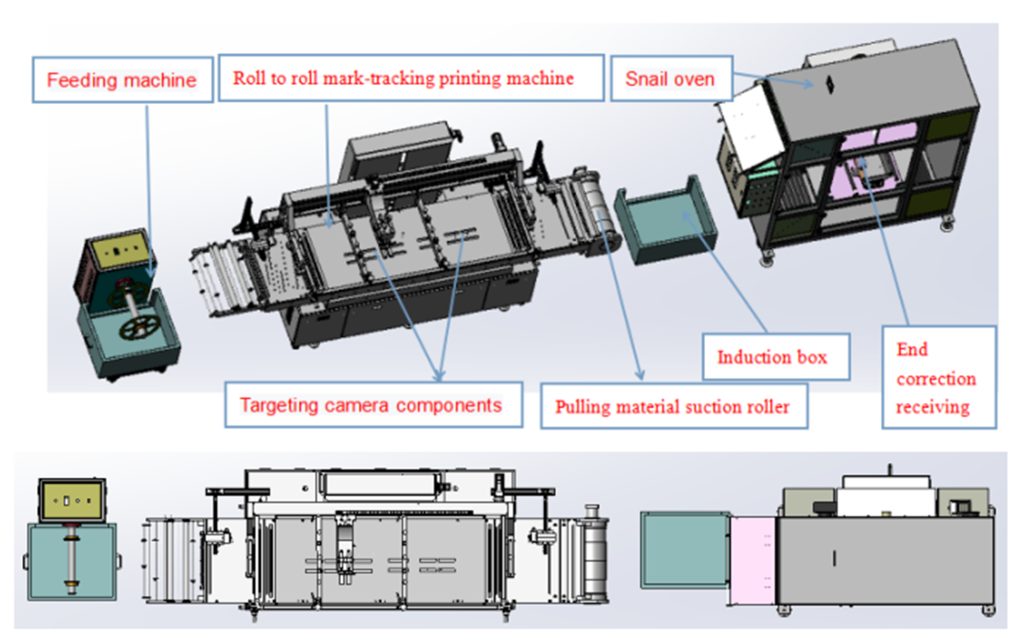

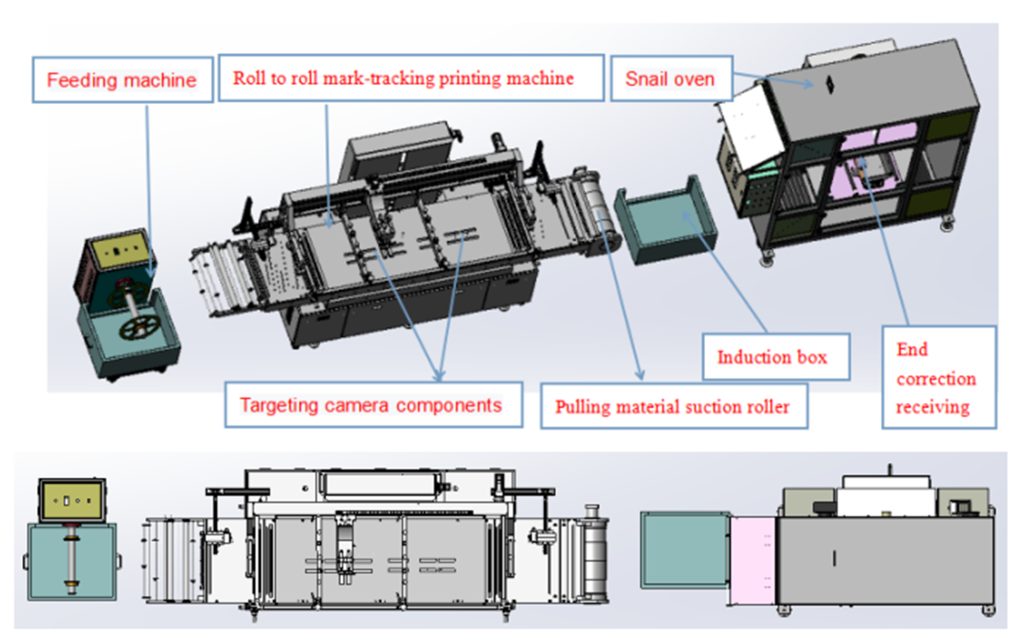

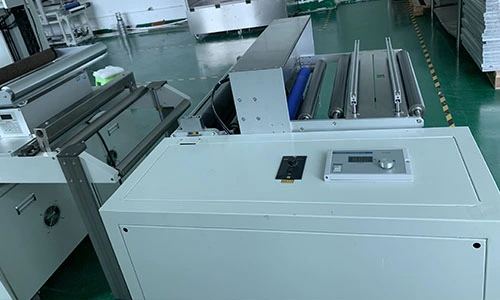

Roll To Roll Mark-Tracking Screen Printing Equippment Diagram:

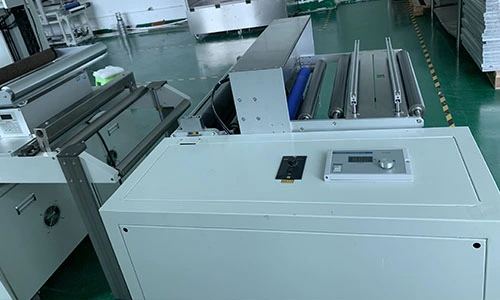

This screen printing machine is composed of a feeder, a printing unit and a hot air dryer.

① The feeder has dust removal rollers, it is able to alarm when the roll material run out.

② The printing unit table has vacuum to fix PET film in position to ensure printing accuracy. It is equipped with three photocell sensors for automatic registration.

③ The hot air dryer has 30M, 60M and 80M length pass for option. It is able to cool and wind cured film into a roll after being dried.

لفة إلى لفة مارك تتبع آلة الطباعة

تطبيق

تتفاعل, heat transfer label, الملصقات والملصقات, مفاتيح الغشاء, تراكب الرسم, IMD, IML, إف بي سي, ملصقات السيراميك, ملصقات خوذة دراجة نارية, لوحة الاسم والأقمشة غير المنسوجة, الخ.

Roll To Roll Mark-Tracking Screen Printing Equippment Features

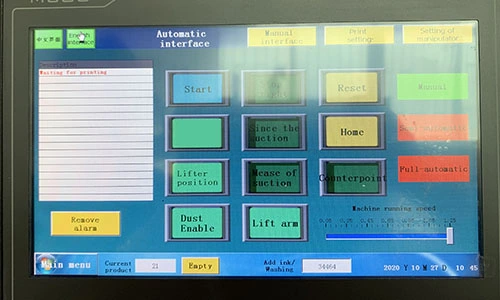

It adopts touch screen man-machine interface control, and the printing adopts photoelectric eye tracking to automatically detect the color mark, and it will automatically stop if there is an abnormality.

Screen position, printing pressure, squeegee speed, plate frame height, الخ. can be set at will; printing speed and printing quantity can be calculated.

Equipped with automatic dust removal function, which can remove the dust of printed materials. The printer is equipped with auxiliary product inspection work lights to facilitate the inspection of defective products.

According to the material requirements, the tension of the machine adopts suction design, strong/weak wind adjustment, intermittent suction design, and reverse blowing function; avoid material scratches.

The squeegee and the ink-returning knife can be adjusted separately. The squeegee can be used on both sides to extend the service life; the ink-returning speed can be set at will.

Dust cover can be added in non-dust-free workshops to avoid poor printing caused by dust falling and the emission of printing ink odor, and the waste discharge rate can reach 75%. The body is equipped with movable rollers for easy handling.

آلة التغذية —–فك اللف

عمود الهواء لفك الأسطوانة مع التحكم في التوتر.

رمح الهواء لفيلم واقية تقشر.

بكرات تنظيف الغبار لتنظيف الفيلم.

جهاز الربط مع فتحة دليل القطع لتوصيل الفيلم بسهولة.

مزيل ثابت—-منفاخ الهواء المؤين.

Automatic stop and alarm when the film run out.

Photoelctric Eye Tracking:

This equipment adopts photoelectric eye tracking to automatically detect the color mark, and it will automatically stop if there is an abnormality.

High-precision photoelectric detector with printing accuracy of 0.1mm.

Electric servo control, high-efficiency automatic variable-speed tracking, high thrust and quick response.

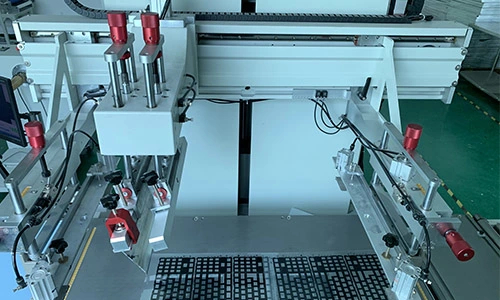

Vacuum Printing Table & Printing Head Vacuum table

with air suction during printing process.

3 مستشعرات للتسجيل التلقائي في اتجاهات X-Y.

الإطار ورأس الطباعة لأعلى لأسفل بواسطة هوائي.

حركة أفقية لرأس الطباعة بواسطة محرك سيرفو.

High precision rails and bearings for running parts.Squeegee dripless design.

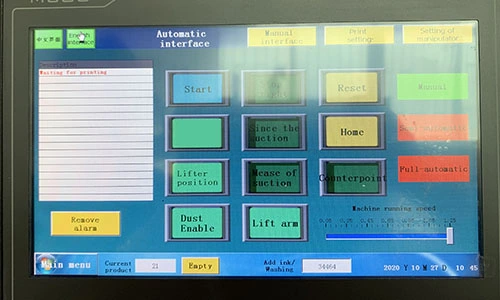

تشغيل الشاشة التي تعمل باللمس

تشغيل الشاشة التي تعمل باللمستحكم PLC سهل الاستخدام جنبا إلى جنب مع شاشة تعمل باللمس لتوفير أقصى قدر من الراحة التشغيلية.

اللغة الافتراضية هي الصينية-الإنجليزية, يمكن للعميل التحويل إلى استخدام, نحن نقبل أيضا تخصيص لغة أخرى.

تستخدم شاشة اللمس للتحكم في رفع رأس الطباعة لتسهيل الصيانة, تحميل, التفريغ والتنظيف للشاشة والكاشطة.

طاولة زجاجية لفحص الجودة

طاولة زجاجية لفحص جودة الطباعة, if there’s quality issue, the buzzer will alarm.

لوحة تحكم بشاشة تعمل باللمس باللغة الإنجليزية.

التذكير التلقائي عند حدوث خطأ في العملية.

باناسونيك PLC للتحكم في الماكينة.

Machine software can be upgraded for long life.

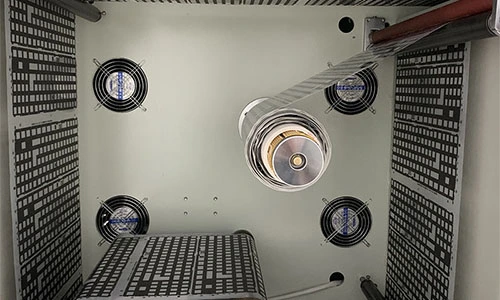

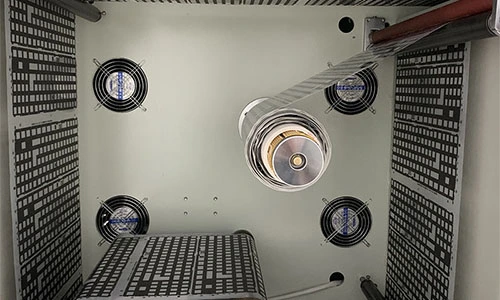

مجفف الهواء الساخن—-الترجيع

طول تمرير فيلم الغرفة 60 امتار.

تتراوح درجة الحرارة من درجة حرارة الغرفة إلى 200 درجة مئوية.

طبقة عازلة للحفاظ على الحرارة داخل الحجرة.

6 مراوح لتبريد الفيلم المعالج.

3 بوصة ضياء. عمود الهواء للف الفيلم المعالج في لفة.

يمكن إضافة آلة تغليف على المجفف.

Shenzhen VILITY Automatic Machinery Co.,Ltd established in 2010 year, located in Shenzhen city, الصين. Our company’s development approach is : People-oriented, Technological innovation , service-oriented. VILITY is a combine-word, comes from Victory& Ability and Victory &Quality which means we always pursue high quality and good service to meet customers requirements and high competitive market. We believe: Service first, customers supreme. VILITY هي شركة تصنيع محترفة, providing ONE-STOP SOLUTION for intelligent printing industry. Recent years, We have pay most of the techniques and technologies to implement Industry 4.0 Robotic. VILITY has been successfully Provide unmanned production lines for many customers. Therefore, it is honored to get a high degree of social affirmation. Our main products are CCD automation alignment machines which included in: CCD دليل ثقب آلة التثقيب, آلة طباعة الشاشة CCD, CCD يموت آلة قطع, CCD Fitting machine, آلة اختبار CCD الأتمتة لطباعة الشاشة, الاجهزه, البلاستيك والصناعات الأخرى. تناسب هذه الآلات كل من المواد المسطحة والمواد من لفة إلى لفة. With substantial ongoing investment in research and development, VILITY is ideally positioned to continue doing high precision CCD robotic machines for both the commercial and domestic markets. We are looking forward to establishing well long –term business relationship with you and your esteemed companies.

After-Sales Service

* Lifelong

* قطع الغيار

* Video technical and online support

* Field maintenance and repair service

* Engineers are available to service machinery overseas.

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, Western Union paying methods. For those orders less than 500USD, we accept PayPal to pay.Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

The screen printing equipment will be packed in woodply case( sea shipping export standard )before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order..

آلة طباعة الشاشة

آلة طباعة الشاشة

تشغيل الشاشة التي تعمل باللمس

تشغيل الشاشة التي تعمل باللمس