Roll to Roll CCD Die Cutting Machine Description:

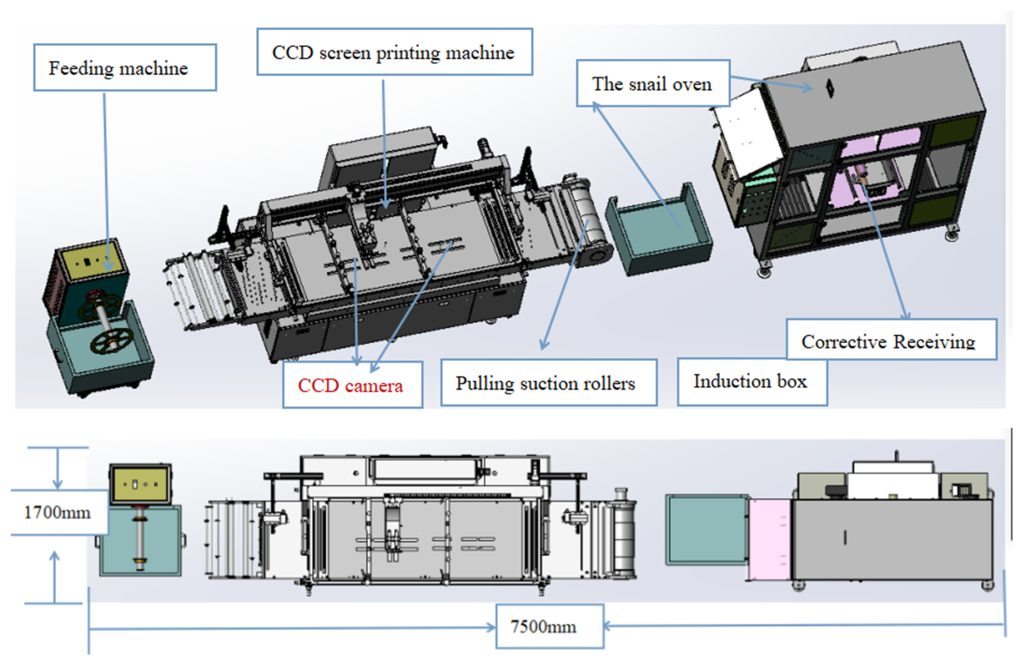

CCD roll-to-roll die-cutting machine is a kind of high-precision and high-efficiency automatic die-cutting equipment. Among them, the equipment mainly contains: CCD moving platform, high precision XYθ alignment platform, pulling mechanism, guiding mechanism, releasing mechanism, punching and cutting mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, الخ. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel.

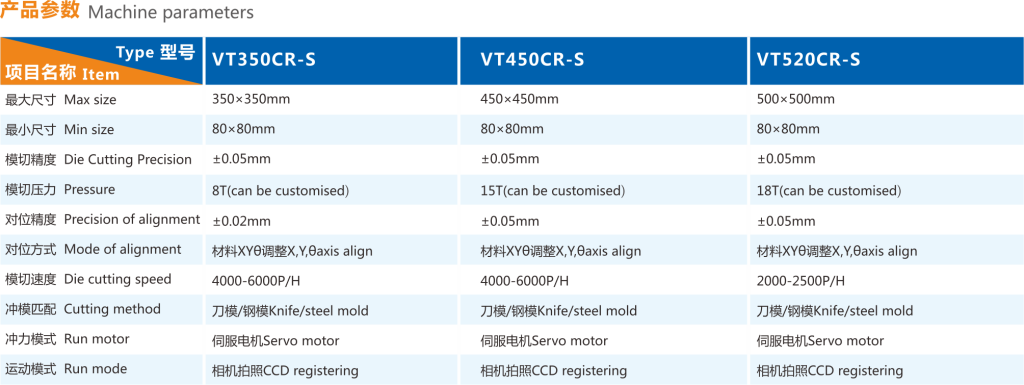

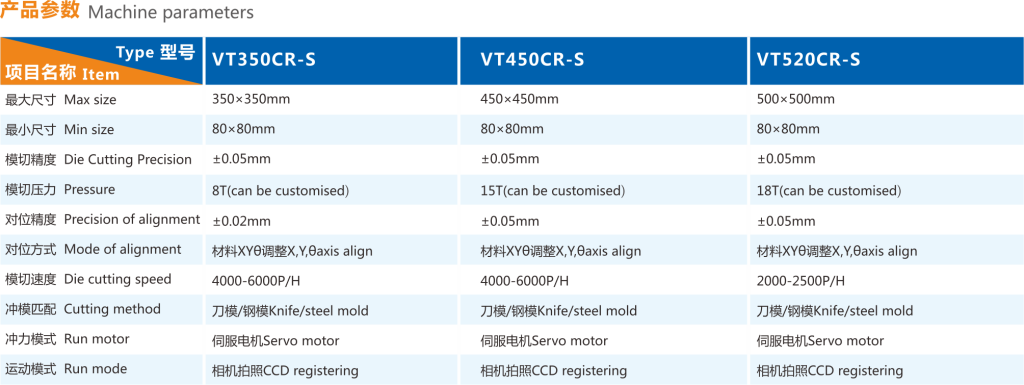

LED FPC Automatic Die Cutter/Die Cutting Machine Specifications:

Performance characteristics:

Suitable for roll-shaped printed materials, equipped with CCD visual recognition alignment and high-speed positioning system to detect the deviation position of the target type, and automatically move the XYθ coordinates to correct the fixed position for punching.

Applied in membrane switches, appliance panels, COB light strips, PET/PVC circuits, diffusion film, FPC double-sided circuit board and other flexible roll material

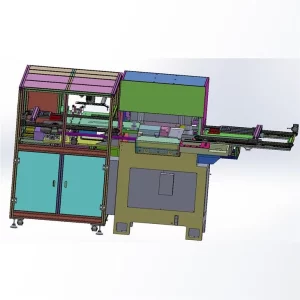

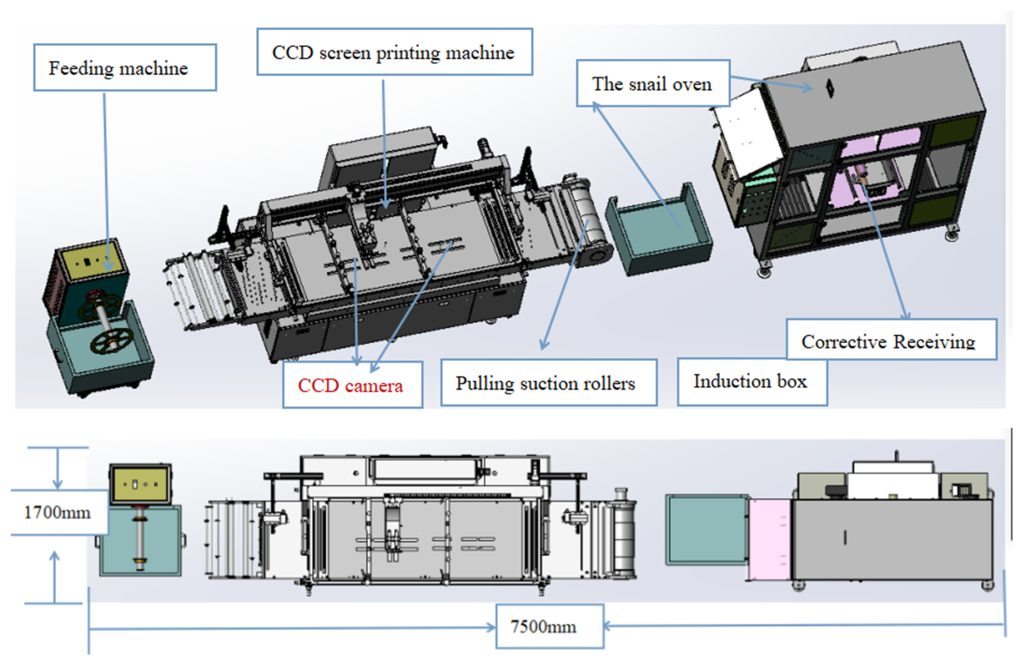

Roll to Roll CCD Camera Registration Die Cutting Machine Structure

This equipment mainly includes die-cutting unit, equipped with CCD moving platform on both sides of the die-cutting unit, high precision XYθ alignment platform, stable alignment, human-machine interface control + button switch, can set a variety of functional parameters, easy to operate; CCD automatic positioning punching, can automatically adjust the field of view of CCD according to the size of the material.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic punching and cutting.

1.Alignment XYθ platform: Alignment XYθ platform is the core part of the machine, used for CCD vision alignment, this alignment platform is composed of XYθ4 axes, with alignment eccentricity function, alignment accuracy can be controlled within 0.02mm.

2.Feeding machine:Feeder is used for coil feeding, die-cutting machine each time cutting, pulling drum will pull a product jump distance, at the same time feeding machine and then feeding.Ensure the efficiency of punching.

Roll to roll CCD regulation die cutting machine

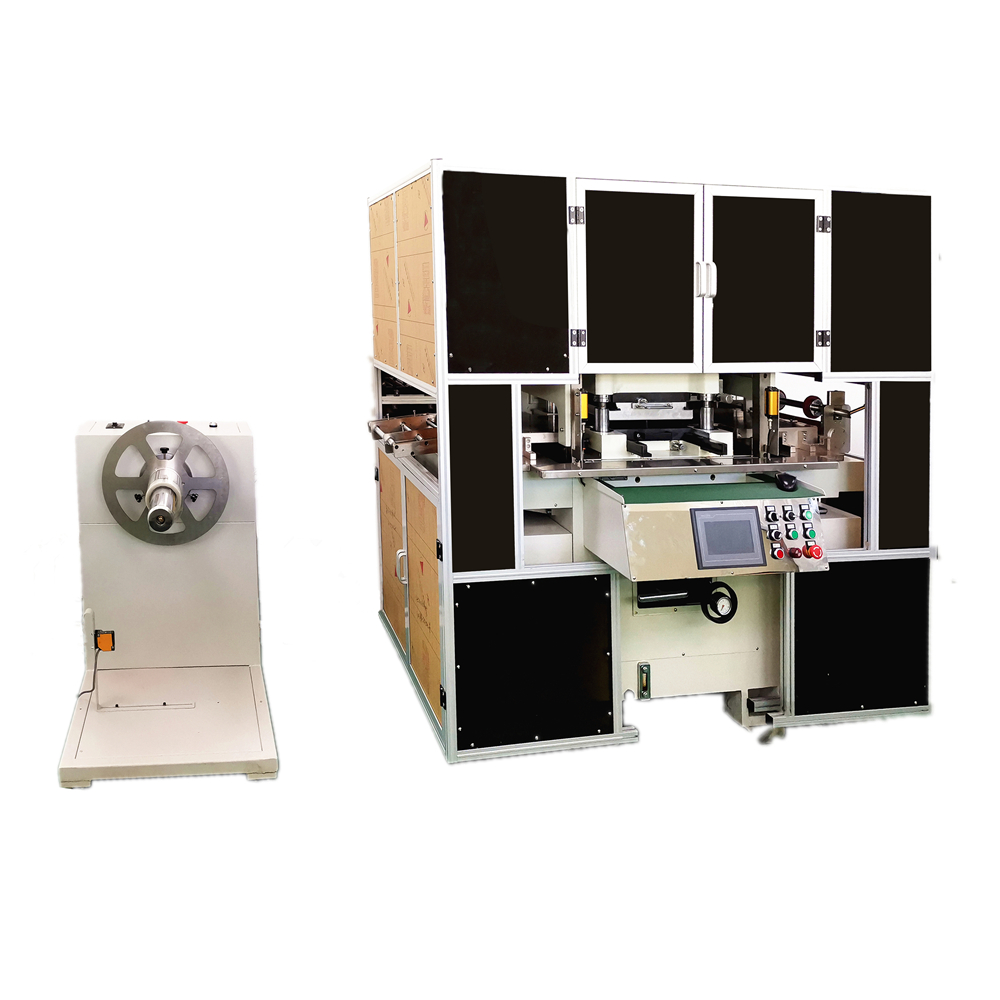

CCD roll-to-roll die-cutting machine is a kind of high-precision and high-efficiency automatic die-cutting equipment. Among them, the equipment mainly contains: CCD moving platform, high precision XYθ alignment platform, pulling mechanism, guiding mechanism, releasing mechanism, punching and cutting mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, الخ. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel. The picture below is the machine design and the actual picture of the die cutting machine.

Electronic Samples Roll to Roll CCD regulation stamping and die cutting machine,Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders.

New Technology (CCD automatic XYθ rotary alignment cutting)

1.CCD automatic XYθ rotation alignment adjustment .

2.Quick screen changer, high production efficiency .

3.CCD high precision alignment ±0.02mm .

4.No pause at halfway, electric eye cursor .

5.No requirements for the accuracy of pulling materials .

6.Provincialworkers, one person can take care of 3 machines.

Automatic Pneumatic Die Cutting Machine Roll to Roll CCD Alignment Die Cutter

Vility Roll to Roll CCD Alignment Die Cutter Product features

- XYθ alignment platform and CCD are fixed on the die-cutting machine to make the alignment smooth.

- The material is fixed on the loading suction platform, easy to operate.

- Punching and cutting accuracy is completely controlled by CCD, accurate positioning.

- Human-machine interface control + button switch, can set a variety of functions and parameters, easy to operate.

- Safety pressure plate, photoelectric switch, emergency stop button, thorough safety protection.

- CCD automatic positioning punching and cutting, can automatically adjust the field of view of CCD according to the size of the material.

- CCD automatically calculates the spatial position of the material and the mold according to the Mark point on the material, and instructs the motor motion control to adjust the platform X, Y, θ, and automatic punching and cutting.

- The equipment will automatically finish punching and cutting when it is adjusted, the number of punching and cutting can be set automatically, and an alarm device is installed for easy management.

- Can be customized according to customer requirements to meet different use requirements.

Q:Are you a factory or a distributor in China?

A:We are a professional factory for 10-years

Q: What kind of ink does your screen printing machine use?

A:All kinds of ink can print, like the solvent ink, water-based ink and plastical

Q: What’s your full automatic screen printing machine speed?

A:10-20 meter/ minute & 600-1200 meter/ hour

Q: How many kinds of material could be printed on?

A:Film & paper is OK, such as PET, البلاستيكيه, بى, BOPP, PP

Q:What’s the material thickness & breadth range?

A:the thickness range: 0.02 -0.5 المليمتر

Q:هل من الممكن أن تعين مهندسين لشركتنا?

A:نعم. يمكن لمهندسينا الذهاب إلى شركتك للحصول على الخدمة في الموقع. لكن, تحتاج إلى دفع الرسوم المقابلة.

Q:هل تقدمون خدمات التركيب والتدريب?

A:نعم, سنوفر لك أدلة التثبيت والتدريب الاحترافية ودروس الفيديو. سيتم أيضا توفير محادثات فيديو مباشرة لإرشادك خلال العملية.

Q:What is your company’s production capacity?

A:30 Sets/ Month.

Q. What other kinds of service can you offer?

A:We can offer screen film, screen ink supplier and various ancillary equipment and accessories

After-sales service is maintenance, not repair

High requirement and High demand label, you can give to Vility fully automatic screen printer

Q:What’s the automatic roll to roll screen printing machine price?

A:Tell the truth, the price is not cheap, the price range is 39,000–190,000$.

As you know, only a reasonable profit can guarantee high quality

Q: What are the Certifications of your machines?

A:We have CE Certificate & ISO Certificate

PACKAGE:

Vility Industry Machine will be packed in strict safety before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the machinery, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

آلة طباعة الشاشة

آلة طباعة الشاشة