Sheet to Sheet CCD Registration Screen Printing Machine + Multi-Layer Rack Receiving Machine Description

Special designed for PCB silk screen printing.

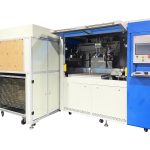

VT6090 CCD multi-layer rack – automatic printing system

Multi-layer Rack – Automatic Printing Line Function

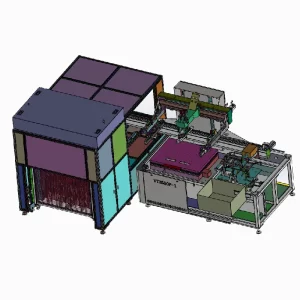

VT6090CCD multi-layer rack – automatic printing line is mainly an automatic production line for printing products according to the process requirements from automatic loading, printing and receiving as a whole. The film is sheet material, the material can be ABS or PC, acrylic board and other series of materials. The process of automatic feeding, initial positioning, printing and receiving is completed in turn, the whole process is automatic and can achieve high efficiency action. The CCD vision system is used for printing, with high positioning accuracy, high speed and stable operation of the equipment.

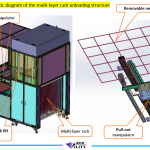

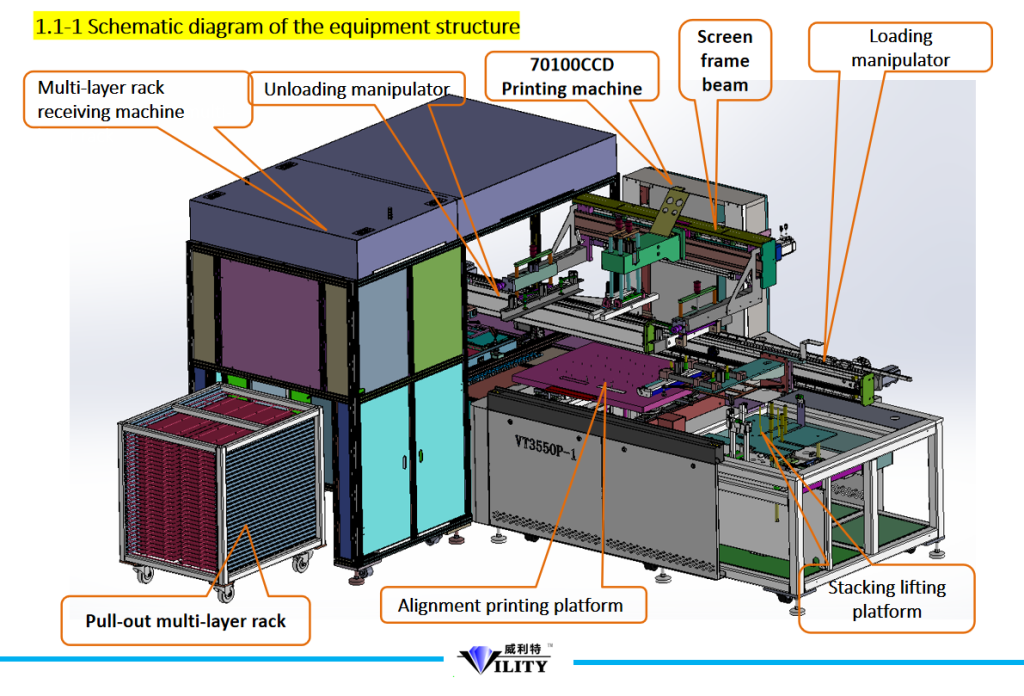

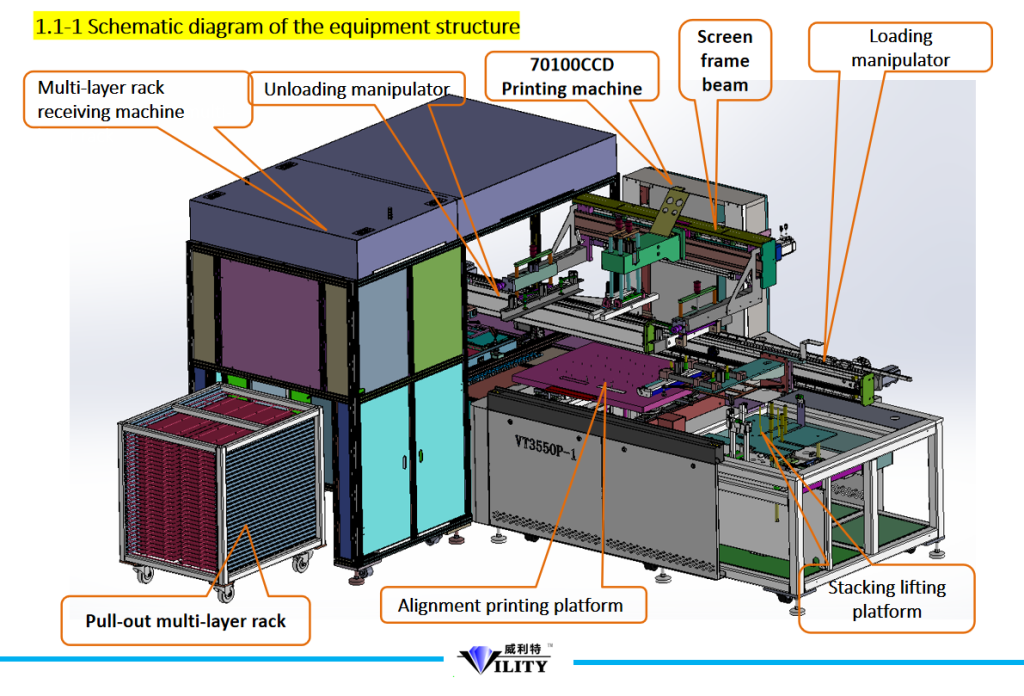

Schematic diagram of the equipment

Schematic diagram of the sheet to sheet precision screen printing equipment

The CCD Alignment Screen Printing System for Sheet Application:

widely used in FPC,HAUSTIER, PVC, transfer paper (Film), floor heating film, geothermal film, electro thermal film, color paper, Film, name plate, flexible circuit board, Handy-Schlüssel, 3 m glue, glue, film switch, trademark laser, scratch CARDS, self-adhesive stickers, paper, ribbon, aluminum foil and copper foil this sheet material silk screen printing.

The CCD Alignment Screen Printing Presses for Sheet is Divided into loading section, unloading section, printing section along with a shuttle table that moves from right to left(optional for printing table to move from left to right). Designed for manual loading /unloading of substrate; once the camera captures the target image the stage auto offsets and subsequently transports to printing section for printing.

Screen frame up/down movement :driven by servo motor and hall screw with clearance tolerance controlled with 50um.

Automatically separate material→auto removal→auto loading→CCD alignment screen printing→auto unloading →dry →auto collecting the finished product.

Siebdrucker + Multi-Layer Sheet Staker Process Flow

1: Manually place the stacking material on the stacking lifting platform, and take the material by the loading manipulator to the printing alignment platform

2: The material on the printing alignment platform is aligned by the CCD, and the alignment platform is moved for calibration

3: After the alignment is completed, lift and move the scraper group to print the product.

4: After printing, the material is taken by the unloading manipulator to the net layer of the multi-layer rack.

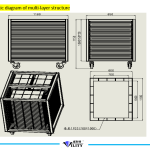

5: When the net layer is full of materials, the net layer manipulator moves the net layer into the multi-layer rack.

6:After the net layer is back in place, the multi-layer rack drops one layer and the net layer manipulator moves the unloaded net layer to the waiting position.

7: After reciprocating to fill the inner net layer of the multi-layer rack, manually push the multi-layer rack away and replace it with a new one.

Multi-Layer Rack Sheet CCD Registration Screen Printing Machine

Multi-Layer Rack Sheet to Sheet CCD Registring Screen Printing Press Features

CCD visual positioning printing, high positioning accuracy;

The whole line adopts automatic feeding, which has a high degree of automation and saves labor;

Using a stable control system, the equipment runs stably, and the use is safe and reliable;

The power drive adopts high-precision accessories such as servo screw to ensure the accuracy and stability of operation;

Simple operation, the touch screen settings are concise and clear, easy to operate.

screen printing machine Main machine feature

(1)

Multicolor printing,

automatic photocell eye counterpoint,

computer control,

automatic detection color code,

if have any abnormal ,

it will stop automatic.

(2)

Using numerical control motor,

printing speed,

return to the ink speed can be set in a random block.

(3) Using numericalcontrol motor, printing distance, return to the ink distance can be set in a random data.

(4)Automatic computing printing, andcalculate the qty, and printing can be set automatically stop.

(5)photoelectric control feeding and discharging to avoid thesurface damage of substrates, can improve the printing quality.

(6)Setting of printing speed and cycle run can be controlled via touch panel.

According to customers’ request, we accept customization, Zum Beispiel, adding anti-dust cover, exhuast cover, drying oven, tunnel furnace, UV curing machine, feeding direction, loading and unloading direction, etc.

The max feeding frame size is 400mmx500mm(can be customized), it can be adjustable after putting material on to fix them, rechte Seite, front and back sides are adjustable, it’s convenient for customer to make adjustment.

The advantage of this machine is printing platform automatic alignment with CCD camera positioning, it’s very suitable for printing multicolors which need high precision, the accuracy of camera positioning is ± 0.02mm, printing accuracy is ± 0.05mm, it can give customers a superior performance, and greatly improved production yield.

The printing scraper and blade adopt imported high level quality stainless steel, expanding printing usinglife, it has a pressure stabilizer ensuring constant pressure at all times.There’s a function that the height and oblique can be adjustable to improve printing quality.

All raw material we adopt high quality stainless steel, beautiful and longlife using.

User-friendly PC based control combined with touch screen monitor for maximum operational convenience.

The default language is Chinese-English, customer can convert to use, we also accept other language customization.

Kundendienst

* Lifelong

* Spare parts

* Video technical and online support

* Field maintenance and repair service

* Engineers are available to service machinery overseas.

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, Western Union paying methods. For those orders less than 500USD, we accept PayPal to pay.Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

The screen printing equipment will be packed in woodply case( sea shipping export standard )before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Aufgrund der großen Größe und der schweren Masse der Druckausrüstung, Für den Transport verwenden wir in der Regel den See- oder Straßentransport. Sie können wählen, ob Sie auf dem Seeweg oder mit dem China-Europe Railway Express transportieren möchten. Was die Handelsbedingungen angeht, Wir übernehmen in der Regel EXW,FOB oder CIF.

The specific way can be confirmed in the process of communication and confirmation of the order..

Siebdruckmaschine

Siebdruckmaschine