Semi-Auto Single Head Guide Hole Drilling Machine

CCD Automatic Guide Hole Drilling Machine/High Precision Hole Drilling Machine/CCD – Camera Controlled Drilling Machine/CCD Target Precision Drill Machine

La máquina perforadora automática de orificios objetivo CCD también se conoce como máquina perforadora automática de objetivos, Taladradora CNC, Taladradora de posicionamiento automático, Diferentes nombres, but actually the same kind of equipment .

High Accuracy Single Head Semi-Auto CCD Guide Hole Drilling Machine for Single PCB Board

Guide Hole Drilling Equipment Application

Vility automatic hole drilling machines applied in printing and packaging, Impresión electrónica, Letreros de placa de identificación y otras industrias Perforación de alineación posterior a la impresión!

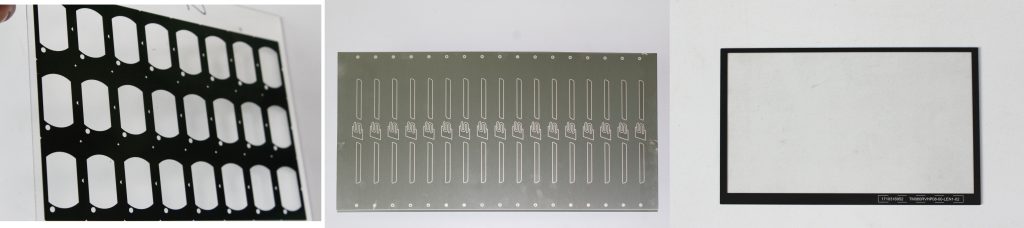

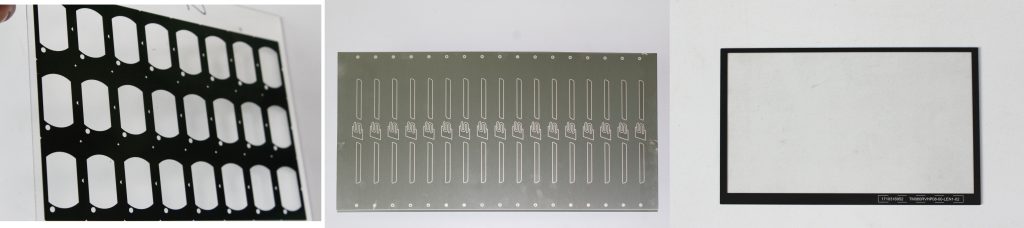

Guide Hole Drilling Equipment Drilled Samples

The hole drilling equipment is used in PCB circuit board, Tablero blando FPC, IMD/IML, película, Hoja de diazo, Panel de teléfono celular, teclado del teléfono celular, sticker, interruptor de membrana, película, PEI, PC, PVC, Película de PET, película de poliéster, Aluminio delgado, sustrato de aluminio, Tablero de fibra de vidrio FR4 y muchos otros materiales.

CCD automatic sheet postion hole drilling machine is suitable for single and double panel, Placa multicapa de PCB, fibra, Panel de PVC, perforación de posicionamiento de láminas de acrílico y otras láminas de plástico frágiles.

Semi-Auto Single Head Guide Hole Drilling Machine features

- Function: Sheet is all OK; CCD fully automatic positioning drilling.

- High accuracy, overall error less than or equal to 0.015mm.

- Fast drilling speed, the average drilling speed is 7-8 times faster than manual drilling speed, only 0.5 seconds per hole.

- No material dragging, accurate positioning of icons and automatic drilling.

- Flexible materials and fragile materials such as acrylic sheets can be drilledby the machine without damaging the material. Fast speed, software can be upgraded free of charge for life.

- Computerised working system, human-machine interface, direct working mode setting on the touch screen, simple and intuitive.

- Special light source identification method, puede identificar automáticamente la figura redonda en varios materiales, automatic alignment drilling.

- Drilling can be viewed directly on the 8″ computer screen or at the drilling station, respectively.

- The presser foot on the machine flattens the film to be drilledduring drilling, making it more accurate.

- Specialised settings are available. The computer system can be upgraded and provides you with a strong professional technical support.

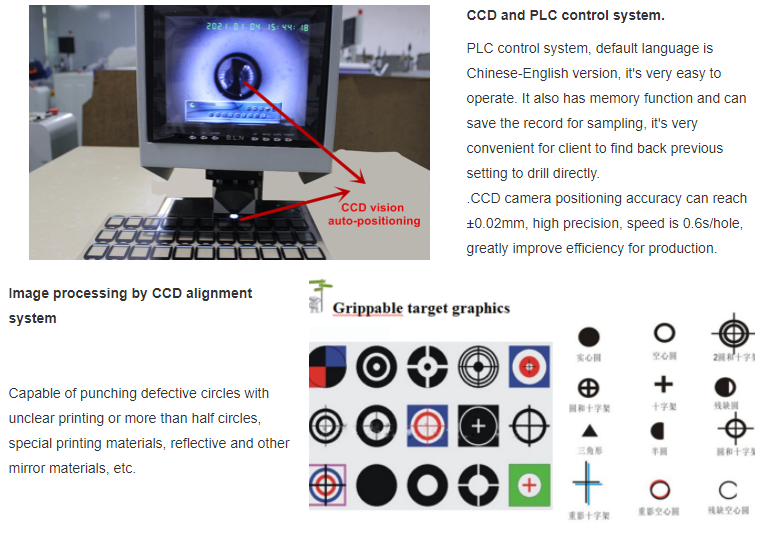

- Image processing: 2-value integrated image processing method.

- Capable of drilling defective circles with unclear printing or more than half circles, special printing materials, reflective and other mirror materials, etc.

Semi-Automatic Target Driller Structurer:

Device configuration:

| Linear guide |

Taiwan HIWIN |

| Pulling material motor |

Chine Leadshine servo motor + type heart reducer |

| CCD 5 million pixels |

Quaternion numerical control |

| Photoelectric switch |

Japan Omron |

| Cojinete |

Japan NSK |

| Cylinder solenoid valve |

Taiwan SHAKO |

| Ball screw |

TBI |

| Mould |

Shenzhen Vility |

Guide Hole Drilling Machine Alignment XYθ platform

This equipment mainly includes hole drilling unit, equipped with CCD moving platform , high precision XYθ alignment platform, stable alignment, human-machine interface control + button switch, can set a variety of functional parameters, Fácil de operar; CCD automatic positioning punching, can automatically adjust the field of view of CCD according to the size of the material.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic hole drilling .

1.Alignment XYθ platform: Alignment XYθ platform is the core part of the machine, used for CCD vision alignment, this alignment platform is composed of XYθ4 axes, with alignment eccentricity function, alignment accuracy can be controlled within 0.02mm.

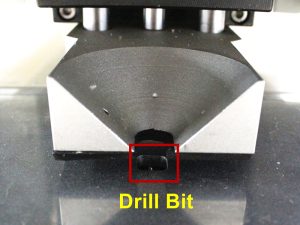

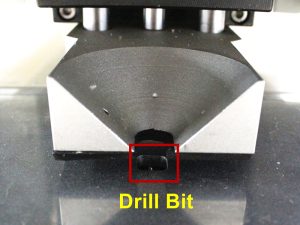

Hole Drilling Machine Drill Bit

High Precision hole positioning

There’s up and down light button, in order to make enough light for camera to identify mark point to drill hole in precision. The blow function is to blow the scrap after drilling, it can keep drilling smoothly all the time.

Semi-Auto Guide Hole Drilling Machine Hole Drilling

Preser foot

Drilling can be viewed directly on the 8″ computer screen or at the drilling station, respectively.

The presser foot on the machine flattens the film to be drilled during drilling, making it more accurate.

CCD and PLC control system.

PLC control system, default language is Chinese-English version, it’s very easy to operate. It also has memory function and can save the record for sampling, it’s very convenient for client to find back previous setting to drill directly. .CCD camera positioning accuracy can reach ±0.02mm, high precision, speed is 0.6s/hole, greatly improve efficiency for production.

FAQ :

Q: ¿Es usted una fábrica o una empresa comercial??

Un: VILITY es una famosa marca de fabricación de la ciudad de Shenzhen, Provincia de Guangdong, China.

Q: ¿Puede hacer un diseño particular de acuerdo con nuestros requisitos??

Un: Sí, Podemos hacer un cambio especial de acuerdo a sus requerimientos.

Q: ¿Cuáles son sus condiciones de pago??

Un : 50% depósito y 50% Saldo antes de la entrega, T/T against copy of Bill of Landing.

Q: ¿Cuál es la capacidad de producción de su empresa??

Un:30 Sets/ Mes.

PAQUETE:

La máquina de la industria Vility se embalará en estricta seguridad antes del transporte. Como se muestra en la siguiente figura. Trate de asegurarse de que no se produzcan daños durante el transporte.

Debido al gran tamaño y a la gran masa de la maquinaria, Generalmente utilizamos el transporte marítimo o por carretera para el transporte. Puede optar por el transporte por ruta marítima o por el Expreso Ferroviario China-Europa. En cuanto a los términos de intercambio, por lo general, adoptamos EXW,FOB o CIF.

La forma específica puede ser confirmada en el proceso de comunicación y confirmación del pedido.

PLAZO DE ENTREGA:

3-20 días después de confirmar el pedido,La fecha de entrega detallada debe decidirse de acuerdo con

Temporada de producción y cantidad de pedido.

Máquina de serigrafía

Máquina de serigrafía