Roll to Roll CCD Die Cutting Machine Description:

CCD roll-to-roll die-cutting machine is a kind of high-precision and high-efficiency automatic die-cutting equipment. Among them, the equipment mainly contains: CCD moving platform, high precision XYθ alignment platform, pulling mechanism, guiding mechanism, releasing mechanism, punching and cutting mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, etc. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel.

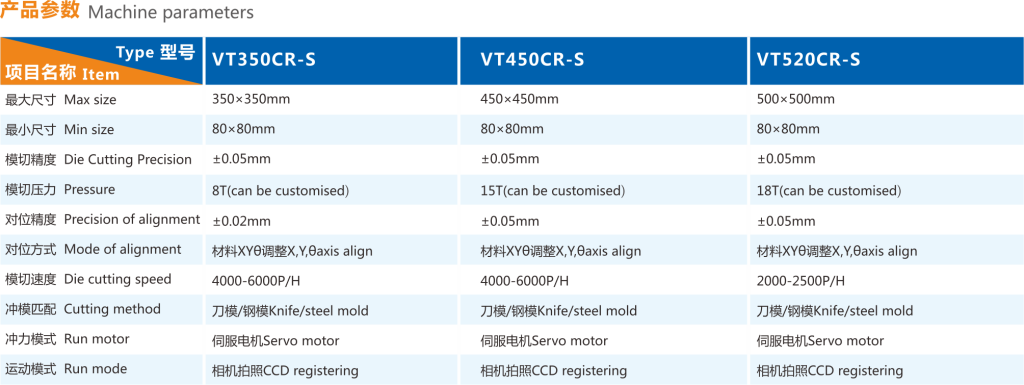

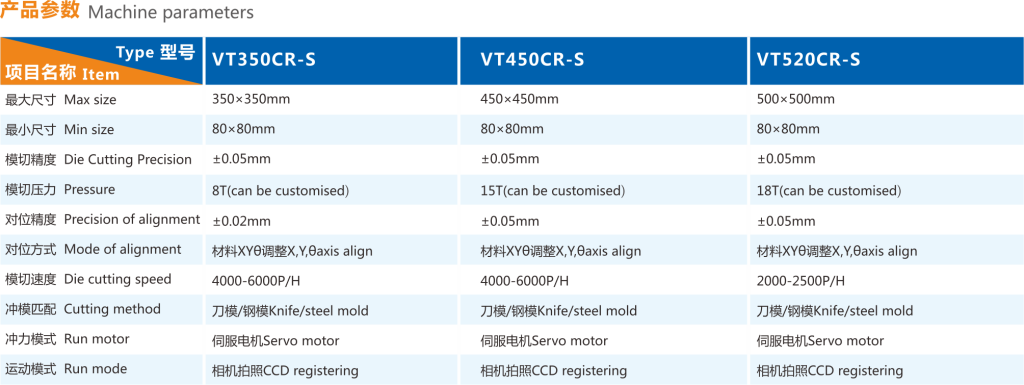

LED FPC Automatic Die Cutter/Die Cutting Machine Specifications:

Performance characteristics:

Suitable for roll-shaped printed materials, equipped with CCD visual recognition alignment and high-speed positioning system to detect the deviation position of the target type, and automatically move the XYθ coordinates to correct the fixed position for punching.

Applied in membrane switches, appliance panels, COB light strips, PET/PVC circuits, película de difusión, FPC double-sided circuit board and other flexible roll material

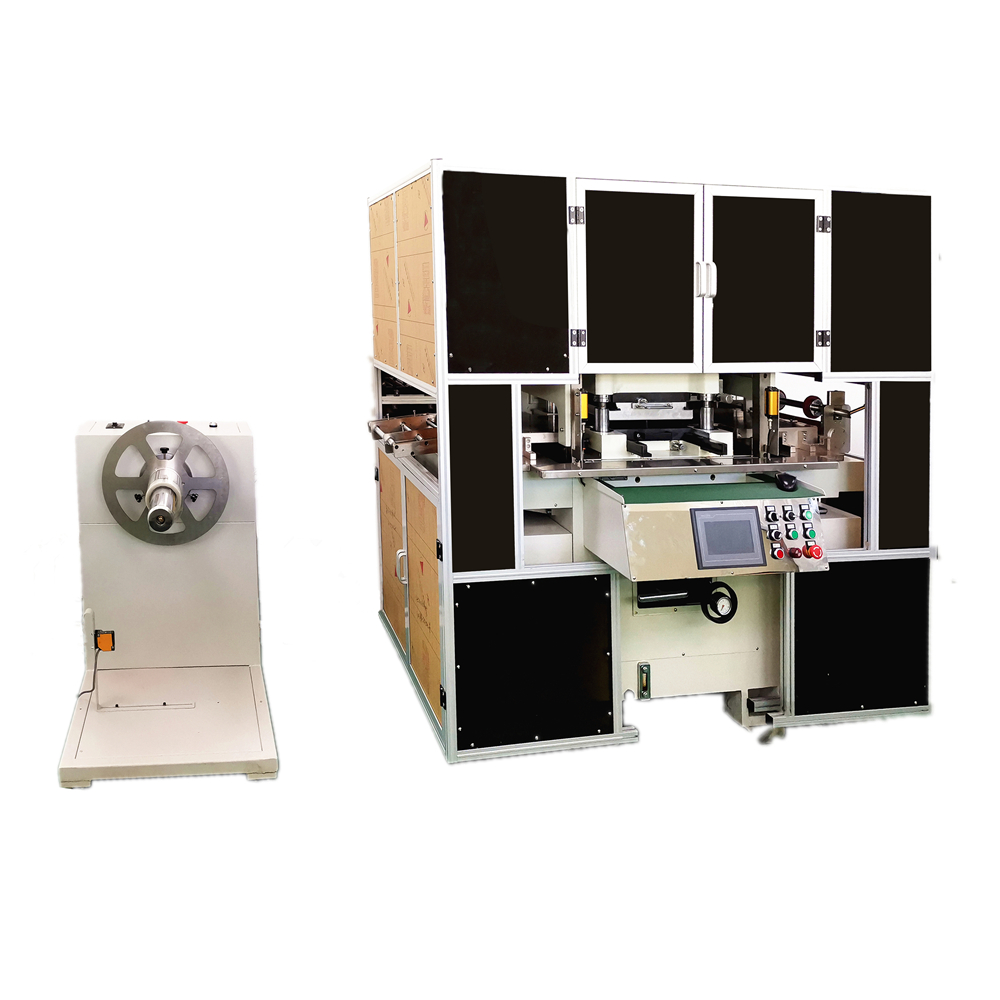

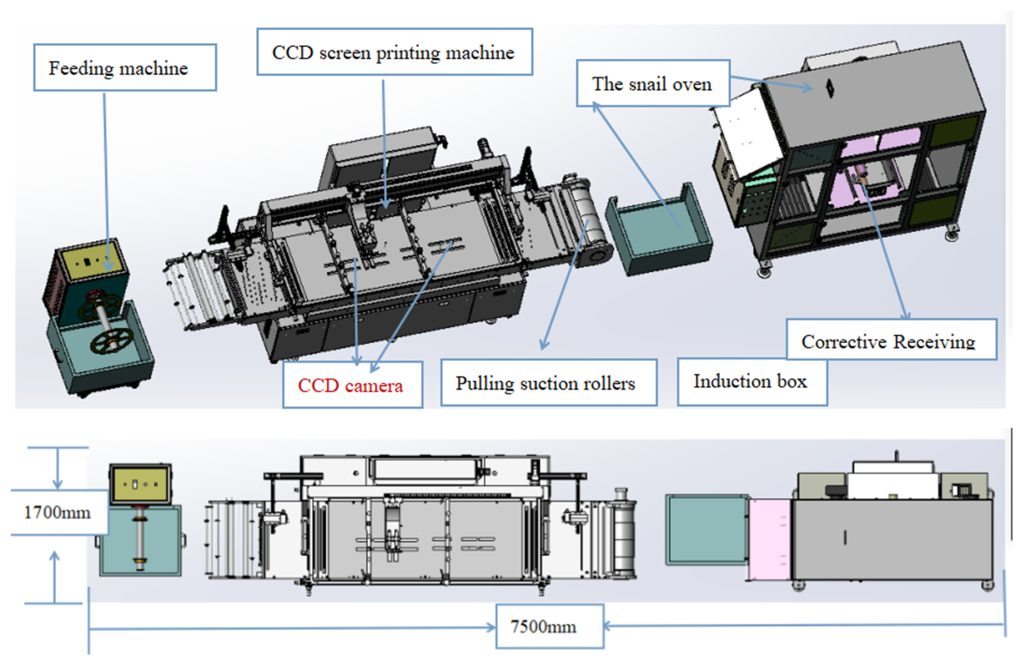

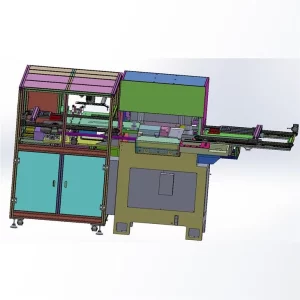

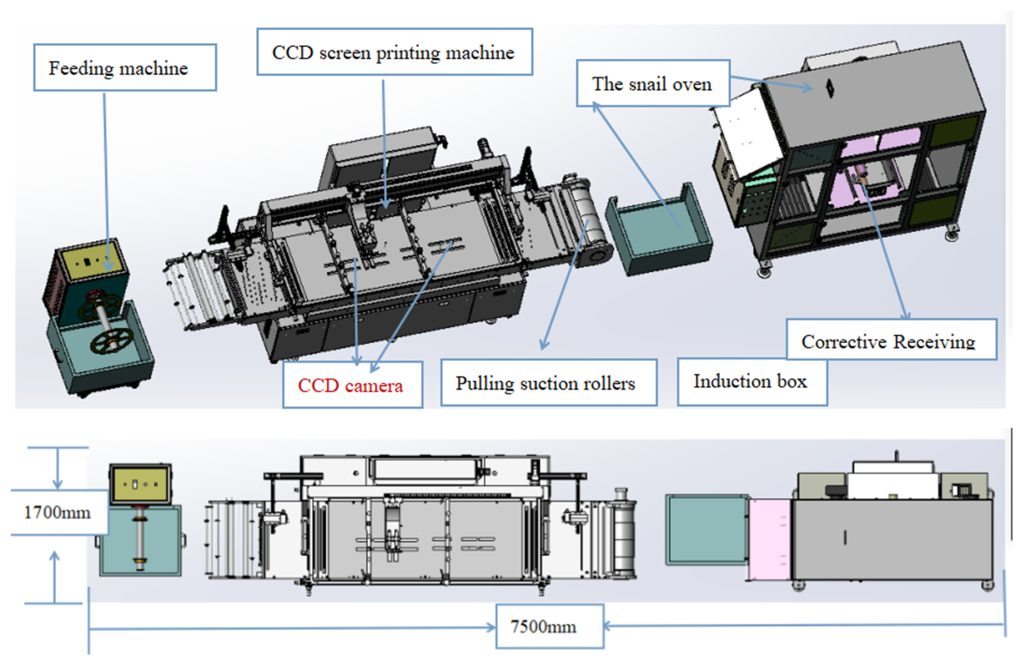

Roll to Roll CCD Camera Registration Die Cutting Machine Structure

This equipment mainly includes die-cutting unit, equipped with CCD moving platform on both sides of the die-cutting unit, high precision XYθ alignment platform, stable alignment, human-machine interface control + button switch, can set a variety of functional parameters, Fácil de operar; CCD automatic positioning punching, can automatically adjust the field of view of CCD according to the size of the material.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic punching and cutting.

1.Alignment XYθ platform: Alignment XYθ platform is the core part of the machine, used for CCD vision alignment, this alignment platform is composed of XYθ4 axes, with alignment eccentricity function, alignment accuracy can be controlled within 0.02mm.

2.Feeding machine:Feeder is used for coil feeding, die-cutting machine each time cutting, pulling drum will pull a product jump distance, at the same time feeding machine and then feeding.Ensure the efficiency of punching.

Roll to roll CCD regulation die cutting machine

CCD roll-to-roll die-cutting machine is a kind of high-precision and high-efficiency automatic die-cutting equipment. Among them, the equipment mainly contains: CCD moving platform, high precision XYθ alignment platform, pulling mechanism, guiding mechanism, releasing mechanism, punching and cutting mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, etc. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel. The picture below is the machine design and the actual picture of the die cutting machine.

Electronic Samples Roll to Roll CCD regulation stamping and die cutting machine,Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

4 steel posts design instead of guide-ways for punching movement and equipping linear guide-way for the front & rear feeders.

New Technology (CCD automatic XYθ rotary alignment cutting)

1.CCD automatic XYθ rotation alignment adjustment .

2.Quick screen changer, high production efficiency .

3.CCD high precision alignment ±0.02mm .

4.No pause at halfway, electric eye cursor .

5.No requirements for the accuracy of pulling materials .

6.Provincialworkers, one person can take care of 3 machines.

Automatic Pneumatic Die Cutting Machine Roll to Roll CCD Alignment Die Cutter

Vility Roll to Roll CCD Alignment Die Cutter Product features

- XYθ alignment platform and CCD are fixed on the die-cutting machine to make the alignment smooth.

- The material is fixed on the loading suction platform, Fácil de operar.

- Punching and cutting accuracy is completely controlled by CCD, accurate positioning.

- Human-machine interface control + button switch, can set a variety of functions and parameters, Fácil de operar.

- Safety pressure plate, photoelectric switch, emergency stop button, thorough safety protection.

- CCD automatic positioning punching and cutting, can automatically adjust the field of view of CCD according to the size of the material.

- CCD automatically calculates the spatial position of the material and the mold according to the Mark point on the material, and instructs the motor motion control to adjust the platform X, Y, θ, and automatic punching and cutting.

- The equipment will automatically finish punching and cutting when it is adjusted, the number of punching and cutting can be set automatically, and an alarm device is installed for easy management.

- Can be customized according to customer requirements to meet different use requirements.

Q:¿Es usted una fábrica o un distribuidor en China??

Un:Somos una fábrica profesional desde hace 10 años

Q: ¿Qué tipo de tinta utiliza su máquina de serigrafía??

Un:Se puede imprimir todo tipo de tinta, como la tinta solvente, tinta a base de agua y plástico

Q: ¿Cuál es la velocidad de su máquina de serigrafía automática completa??

Un:10-20 metro/minuto & 600-1200 Metro/hora

Q: ¿En cuántos tipos de material se puede imprimir??

Un:Película & El papel está bien, como el PET, PVC, PEI, BOPP, PP

Q:¿Cuál es el grosor del material? & Rango de amplitud?

Un:El rango de espesor: 0.02 -0.5 milímetro

Q:Is it possible for you to assign engineers to our company?

Un:yes. Our engineers can go to your company for on-site service. Sin embargo, you need to pay the corresponding fee.

Q:¿Ofrecen servicios de instalación y formación??

Un:Sí, Le proporcionaremos manuales profesionales de instalación y capacitación y tutoriales en video. También se proporcionarán conversaciones de video en vivo para guiarlo a través de la operación.

Q:¿Cuál es la capacidad de producción de su empresa??

Un:30 Sets/ Mes.

Q. ¿Qué otros tipos de servicios pueden ofrecer??

Un:Podemos ofrecer películas de pantalla, proveedor de tinta para serigrafía y diversos equipos y accesorios auxiliares

El servicio postventa es mantenimiento, no reparar

Etiqueta de alta exigencia y alta exigencia, puede dar a la impresora de pantalla totalmente automática Vility

Q:What’s the automatic roll to roll screen printing machine price?

Un:Tell the truth, the price is not cheap, the price range is 39,000–190,000$.

As you know, only a reasonable profit can guarantee high quality

Q: ¿Cuáles son las certificaciones de sus máquinas??

Un:Contamos con Certificado CE & Certificado ISO

PAQUETE:

La máquina de la industria Vility se embalará en estricta seguridad antes del transporte. Como se muestra en la siguiente figura. Trate de asegurarse de que no se produzcan daños durante el transporte.

Debido al gran tamaño y a la gran masa de la maquinaria, Generalmente utilizamos el transporte marítimo o por carretera para el transporte. Puede optar por el transporte por ruta marítima o por el Expreso Ferroviario China-Europa. En cuanto a los términos de intercambio, por lo general, adoptamos EXW,FOB o CIF.

La forma específica puede ser confirmada en el proceso de comunicación y confirmación del pedido.

PLAZO DE ENTREGA:

3-20 días después de confirmar el pedido,La fecha de entrega detallada debe decidirse de acuerdo con

Temporada de producción y cantidad de pedido.

Máquina de serigrafía

Máquina de serigrafía