Vility Automatic Roll to Roll CCD Registration Screen Printing Machine Overview

Fully Automatic Roll-to-Roll Screen Printing Line, Fully Automatic RtR Screen Printing Equipment, Fully Automatic Reel-to-Reel Screen Press,

CCD enregistrement des imprimantes sérigraphiques, Machines d’impression pour une large application

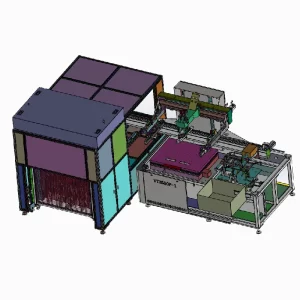

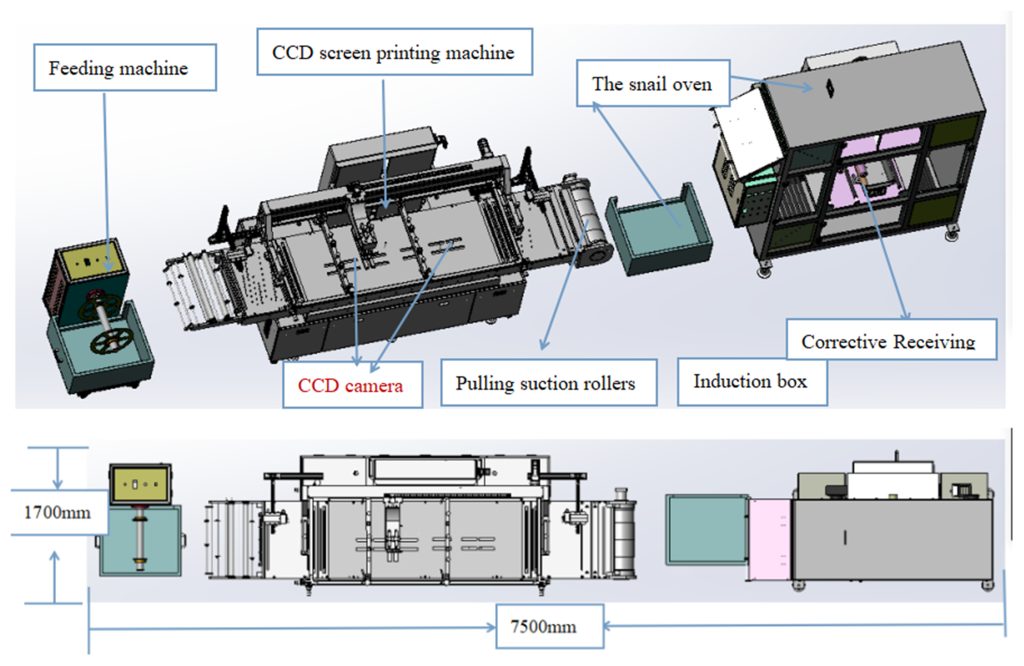

Fully Automatic Reel-to-Reel Screen Printing System Structure

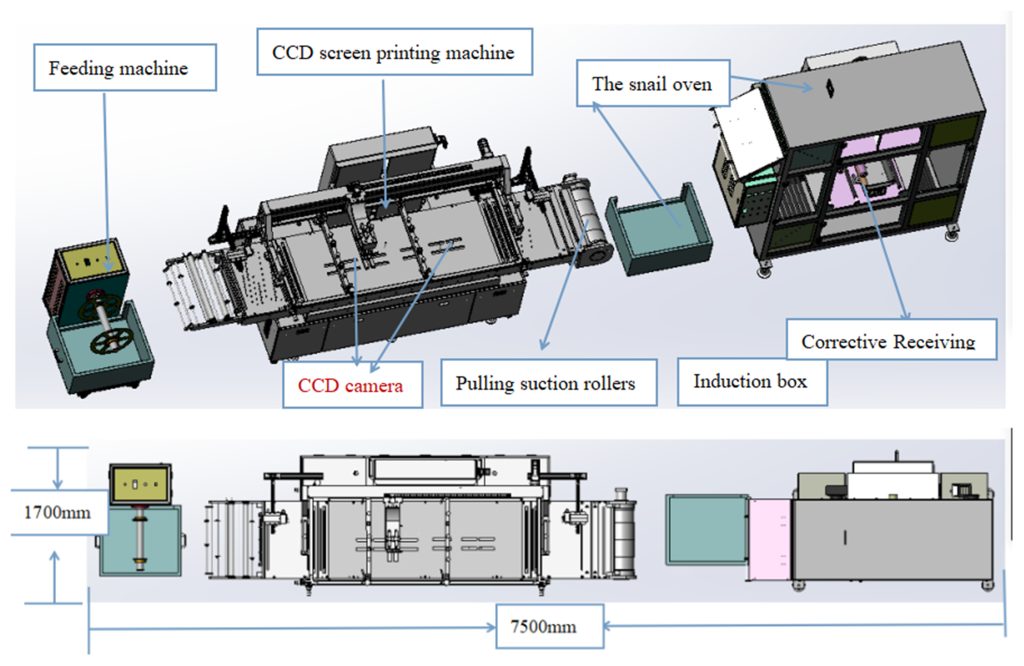

Roll to roll CCD alignment screen printing machine consists of three main parts: automatic feeding machine, CCD precision printing machine and automatic oven.

The whole production line can be controlled by one person, no pause in the printing process, high precision.The alignment error shall not exceed 0.02mm.

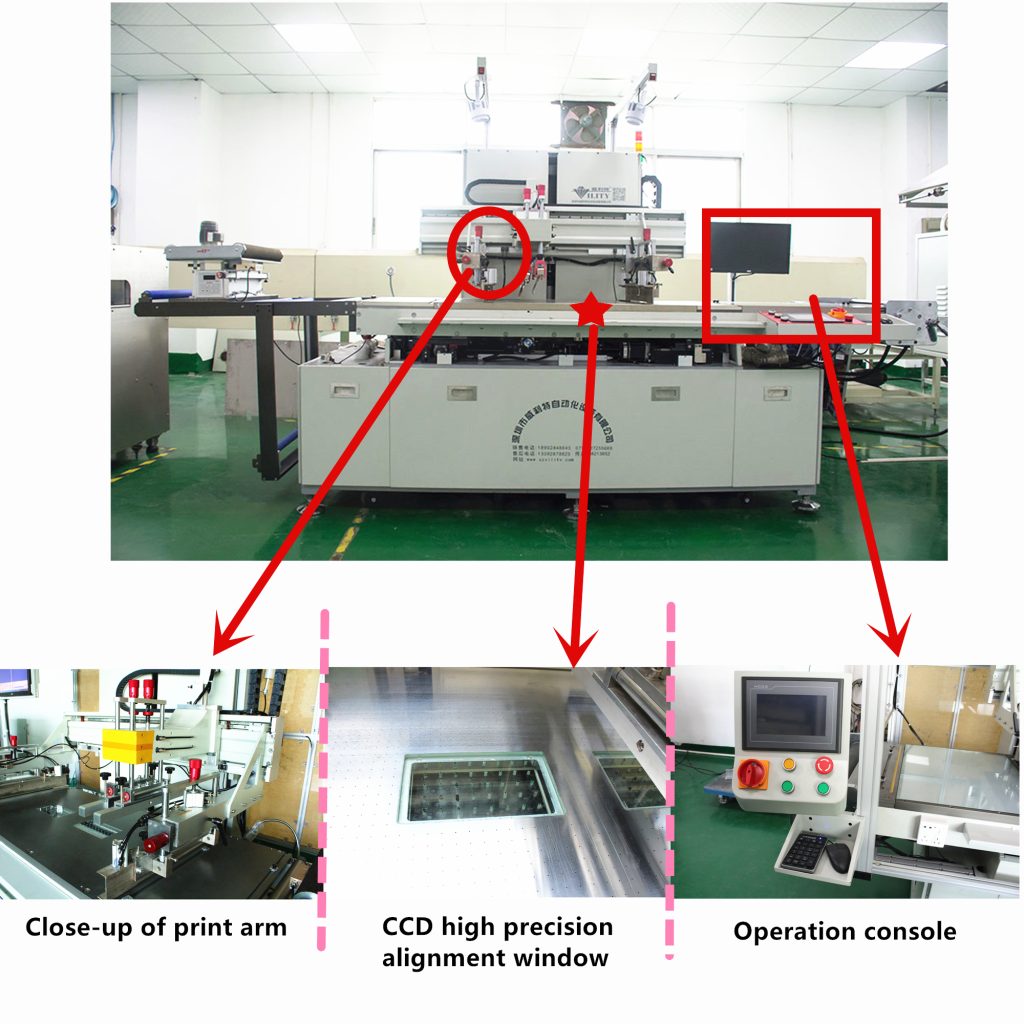

Roll to roll precision screen printing Machine Structure

Automatic CCD Positioning Screen Printing Machine For Roll To Roll Application :

The Fully Automatic Reel-to-Reel Screen Press is widely used in FPC,PET, Chlorure de polyvinyle, varies of label,transfer paper (film), floor heating film, geothermal film, electro thermal film, color paper, film, name plate, flexible circuit board, Clés de téléphone portable, Membrane switch, trademark printing, scratch CARDS, self-adhesive stickers, paper, ribbon, aluminum foil and copper foil this roll material silk screen printing.

High precision CCD vision alignment with 0.02mm error. Suitable for all flexible roll material printing.

Fully Automatic Roll-to-Roll Screen Printing Line Working Procedure:

Raw material →Automatic feeding machine →Automatic printing→Automatic UV or oven →Automatic receiving →End product.

Roll to Roll Automatic Screen Printing Machine Manufacturer Factory Shop

Fully Automatic High Precision RtR Screen Printing Equipment Features

(1). CCD automatic alignment system, if the similarity is not within the setting range, any abnormal, it will stop and automatically start adjust the alignment successful and continue to work.

(2). Using numerical control motor, printing speed, return to the ink speed can be set in a random block.

(3). Using numerical control motor, printing distance, return to the ink distance can be set in a random data.

(4). Automatic computing printing, and calculate the qty, and printing can be set automatically stop.

(5). photoelectric control feeding and discharging to avoid the surface damage of substrates, can improve the printing quality.

Roll to roll precision screen printing machine structure

Automatic Roll Material Loading Machine of Screen Printing Mahcines

Automatic Roll Material Feeder:

(1). Photoelectric control feeding, avoid the surface damage of the material.

(2). Feeding speed, time, can adjust at will.

(3). The feeding starting speed, can adjust at will, start frequency starting from 0 up to run slowly, avoid the start too fast,

cause the material surface scratches.

(4). Equipped with an automatic protective device.

Hot Air Drying Oven for Screen Printing Machine

Hot Air Drying Oven :

(1).Circulating hot air drying, temperature adjustable, automatic winding.

(2).The oven cover an small area, 32-60 meters length,

which can realize low temperature drying, ensure

printed material no shrinkage deformation,

multicolor printing.

With Vility Roll to Roll Automatic Screen Printing Machine

You can do automatic silk screen printing for below industry:

1/Mobile phone: case, shell, screen glass, circuit board , shading of screen and so on.

2/ Auto: Glass panel, Dashboard, automatic films, some auto decoration, many many application on auto industry.

3/ Printed Circuit: all kinds of circuit board and circuit film as well as membranes.

4/ IMD/IML, plastics industries….

Customization:

1/ CCD visual Alignment System, It’s the most advanced alignment technology used in screen printing. And the error can be kept in degree of microns.

2/ IR alignment and mark tracing system. Traditional working mode, widely accept by printing industries. Keep error in degree of millimeter.

3/Multi-colors Production Line. Depends on the types of ink and material, Printing unit can be linked up, and made multi-colors. Solution details need further discussion.

Precision Screen Printing Machine With Hot Air Drying Ove

Vility Roll Screen Printing Machine Features :

1. IR sensor for feeding and transport as well as rewinding. No jiggle when working situation.

2. Equipped with Panasonic servo motor, Efficient and stable, precise positioning.

3. Smart Operating system, language switch available. Smart, concise, and convenient.

4. Compact Design and durable metal plate, interrupteur photoélectrique, Bouton d’arrêt d’urgence, Intelligent protection.

5. CCD automatic positioning and printing, automatically position adjusted according to the camera. Working table is rotary.

6. All working unit got dedusting function.

7. Labor saving, Automatic production line.

Q:Êtes-vous une usine ou un distributeur en Chine ??

Un:Nous sommes une usine professionnelle depuis 10 ans

Q: Quel type d’encre votre machine de sérigraphie utilise-t-elle ??

Un:Tous les types d’encre peuvent imprimer, comme l’encre à solvant, encre à base d’eau et plastique

Q: Quelle est la vitesse de votre machine de sérigraphie entièrement automatique?

Un:10-20 mètre/ minute & 600-1200 mètre/ heure

Q: Combien de types de matériaux pourraient être imprimés?

Un:Film & le papier est OK, tels que le PET, Chlorure de polyvinyle, PE, BOPP, PP

Q:Quelle est l’épaisseur du matériau ? & Gamme étendue?

Un:la gamme d’épaisseur: 0.02 -0.5 mm

La gamme Wideth: 310-1600mm

Q. Quels autres types de services pouvez-vous offrir ??

Un:Nous pouvons offrir un film d’écran, fournisseur d’encre de sérigraphie et divers équipements et accessoires auxiliaires

Le service après-vente est la maintenance, pas réparer

Étiquetage à exigences élevées et à forte demande, vous pouvez donner à l’imprimante d’écran entièrement automatique Vility

Q:Quel est le prix de la machine de sérigraphie automatique rouleau à rouleau?

Un:Dire la vérité, Le prix n’est pas bon marché, the price range is 39,000–190,000$.

Comme vous le savez, Seul un bénéfice raisonnable peut garantir une qualité élevée

Q: Quelles sont les Certifications de vos machines?

Un:Nous avons le certificat CE & Certificat ISO

Votre satisfaction est notre honneur!

COLIS:

The Automatic Roll to Roll CCD alignment screen printing machine will be packed in strict safety before transportation.As shown in the figure above.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, Nous utilisons généralement le transport maritime ou routier pour le transport. Vous pouvez choisir de transporter par voie maritime ou par China-Europe Railway Express. En ce qui concerne les termes de l’échange, nous adoptons généralement EXW,FOB ou CIF.

La manière spécifique peut être confirmée dans le processus de communication et de confirmation de la commande.

DÉLAI DE LIVRAISON:

3-20 jours après confirmation de la commande,La date de livraison détaillée doit être décidée en fonction de

Saison de production et quantité commandée.

Machine de sérigraphie Emballage

Manière d’expédition de machine de sérigraphie

Machine de sérigraphie

Machine de sérigraphie