Roll to Roll Double-Head Auto CCD Punching Machine Description

Double-Needles Automatic Guide Hole Punching Machine can automatically double-sided positioning and punching marked holes. With static elimination device, can advise the pulling precision automatically

and equpped with die cutting machine or receiver machine at the end of this machine.Automatic one time punching for one side: Anti-dust cleaning system before cleaning.Self-contained static elimination equipment, closed loop feedback between CCD and pulling system, automatic correction of pull error, automatic unwinding automatic punching machine.

Roll To Roll Dual-Head CCD Guide Hole Punching Machine

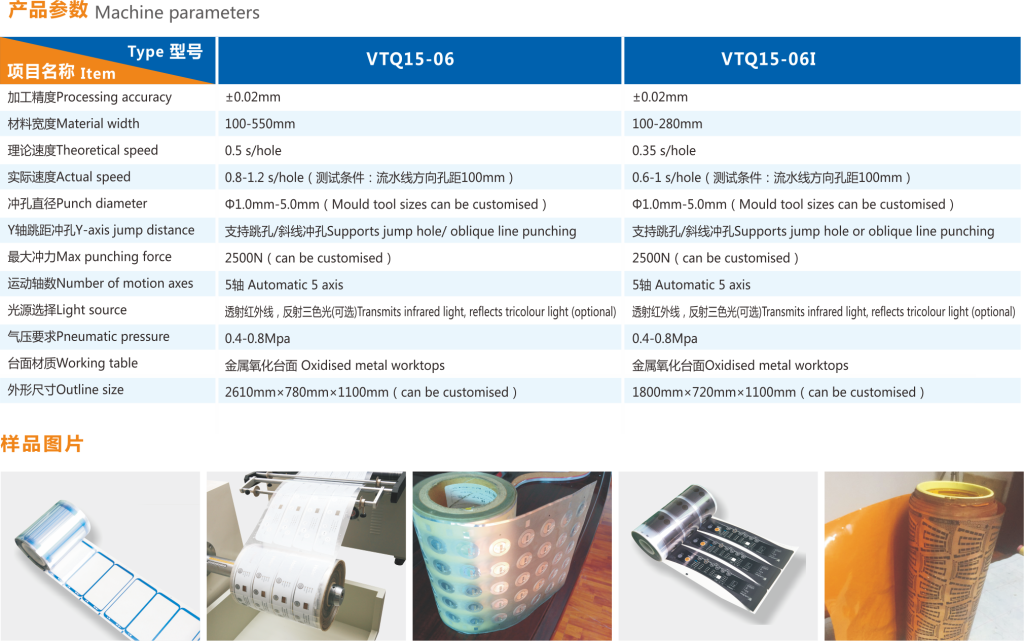

Specications of Double-Needles Automatic Guide Hole Punching Machine For Flexible Roll To Roll Material

Double-Needles Automatic Guide Hole Punching Machine For Flexible Roll To Roll Material

Double Needles Roll To Roll Automatic CCD Camera Guide Hole Dual Puncher application

Applied to Mobile phone keypad, pannello per telefono cellulare, conductive film, interruttore a membrana, film, IMD/IML,FPC and other flexible roll to roll material;

All kinds of trademarks, labels, cell phone keys, cell phone panels, conductive film, interruttori a membrana, film, IMD/IML, Circuiti stampati flessibili FPC, PET/PVC/PC/PP and other flexible coil positioning hole punching and roll material slicing.

Easy operation automatic CCD camera positioning punching Features

1. High accuracy of punching target. Adopt computer control, CCD camera positioning, imported precision screw guide drive, equipped with precision punching tools, imported cylinder control punching. Ensure the punching error: ≤±0.02mm.

2.The working mechanism adopts the combination of mechanical and pneumatic, with stable performance and much higher punching force.

3.Put the product to be punched into the visual range of CCD, the punching machine will automatically capture the punching pattern and automatically move to complete the punching, the whole process only takes 0.4 seconds.

4.Specify the hole pattern to be punched directly on the computer screen to set the working mode, easy to operate; special alloy steel lower die, durable; high-speed white steel punching needle, smooth punching mouth.

English (customizable language) operation interface with touch screen operation.

5.Special light source identification system, can automatically identify the round figure on various materials, automatic alignment punching. It can realize fully automatic bilateral and multilateral one-time positioning punching, double drill, can realize punching 2 holes at one time.

Vility Automatic Punching Machine Advantage:

1. Efficiency advantage: The efficiency of automatic double-headed punching machine is 3-4 times the efficiency of ordinary single-headed automatic punching machine, an automatic positioning punching machine greatly improves production efficiency.

2. Labor advantage: Single-headed automatic punching machine requires manual discharge, e 1 person can only operate one machine, while automatic punching machine can operate more than one machine at the same time, saving labor.

3. Functional advantage: Automatic positioning punching machine is automatic feeding, automatic positioning punching, automatic de-static, automatic cutting/receiving/die-cutting in one, one machine can realize multiple functions, which is the best choice for enterprises to realize automation.

4. Matching advantage: Many large enterprises are equipped with automatic screen printing machine, and automatic punching machine can effectively match the next process of automatic screen printing machine to realize enterprise automation.

5. Working environment: At present, the market is difficult for enterprises to recruit workers, so it is especially important to realize enterprise automation. With automatic positioning punching machine, enterprises will be transformed from the original physical technical work to easy non-technical work, the working hours can be properly extended, the working environment is greatly improved, which can effectively reduce the work pressure of workers, while helping to alleviate the problem of difficult recruitment of enterprises.

6. Process advantage: automatic positioning punching machine is automatic feeding, automatic positioning punching, automatic de-static, automatic cutting in one, can effectively save the cutting process, but also for enterprises to save the equipment and labor costs required for cutting.

Q:Are you a factory or a distributor in China?

A:We are a professional factory for 10-years

Q: What kind of ink does your screen printing machine use?

A:All kinds of ink can print, like the solvent ink, water-based ink and plastical

Q: What’s your full automatic screen printing machine speed?

A:10-20 meter/ minute & 600-1200 meter/ hour

Q: How many kinds of material could be printed on?

A:Film & paper is OK, such as PET, PVC, PE, BOPP, PP

Q:What’s the material thickness & breadth range?

A:the thickness range: 0.02 -0.5 millimetro

the breadth range: 310-1600millimetro

Q. What other kinds of service can you offer?

A:We can offer screen film, screen ink supplier and various ancillary equipment and accessories

After-sales service is maintenance, not repair

High requirement and High demand label, you can give to Vility fully automatic screen printer

Q:What’s the automatic roll to roll screen printing machine price?

A:Tell the truth, the price is not cheap, the price range is 39,000–190,000$.

As you know, only a reasonable profit can guarantee high quality

Q: What are the Certifications of your machines?

A:We have CE Certificate & ISO Certificate

Your Satisfaction is Our Honor!

PACCO:

Vility Industry Machine will be packed in strict safety before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the machinery, Generalmente utilizziamo il trasporto marittimo o stradale per il trasporto. Puoi scegliere di trasportare via mare o tramite espresso ferroviario Cina-Europa. Per quanto riguarda le ragioni di scambio, adottiamo solitamente EXW,FOB o CIF.

La modalità specifica può essere confermata nel processo di comunicazione e conferma dell'ordine.

TEMPI DI CONSEGNA:

3-20 giorni dopo la conferma dell'ordine,La data di consegna dettagliata deve essere decisa in base

Stagione di produzione e quantità di ordine.

Macchina serigrafica

Macchina serigrafica