自動シート・バイ・シート高精度フィルム-ティアリング・スクリーン印刷機 説明

自動シート・バイ・シート・フィルム-ティアリング・スクリーン印刷装置/自動シート・バイ・シート・フィルム-ティアリング・スクリーン印刷プリンター/自動シート・バイ・シート・フィルム-ティアリング・スクリーン・プレス

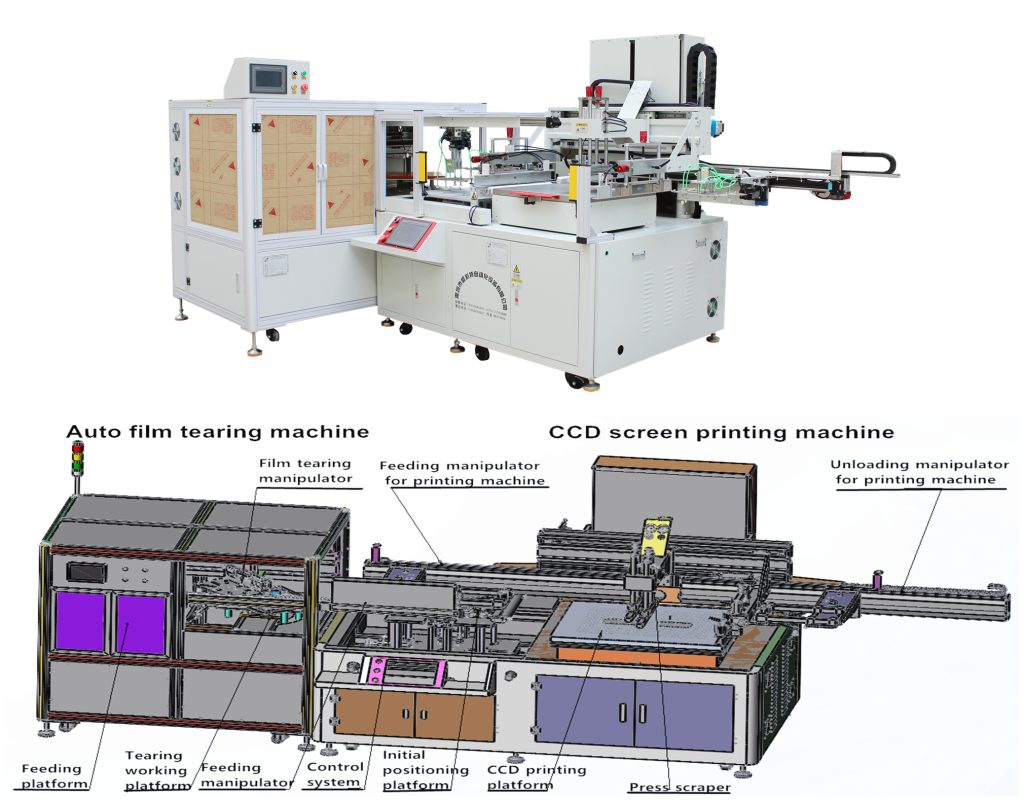

フィルム引き裂き機を備えた自動アライメント印刷機は、従来のCCD印刷機に自動フィルム引き裂き機を追加したものです. 印刷前にシートの保護フィルムを剥がす必要がある精密材料に使用されます.

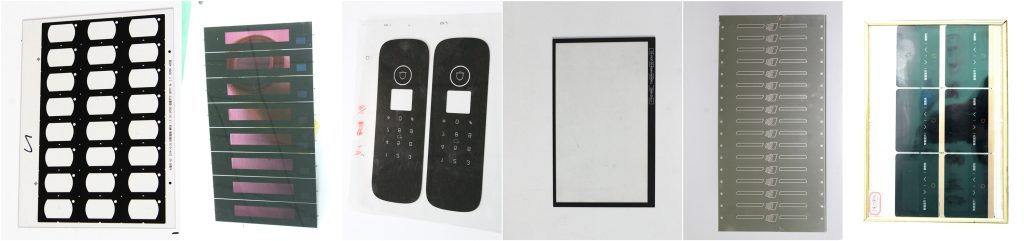

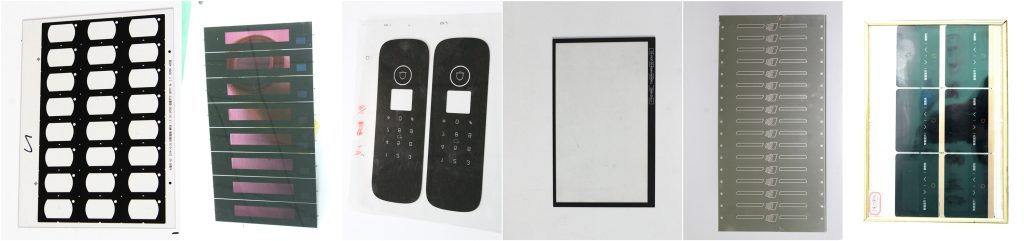

フィルム引き裂きを備えた自動整列印刷機は、次のようなシート材料への印刷に適しています: メンブレンスイッチ, ガラスカバー, アクリル, 伊藤, 導電性フィルム, 複合材の裏表紙, 等.

高いアライメント精度, 印刷速度が速く、生産ライン全体を1人で操作できます.

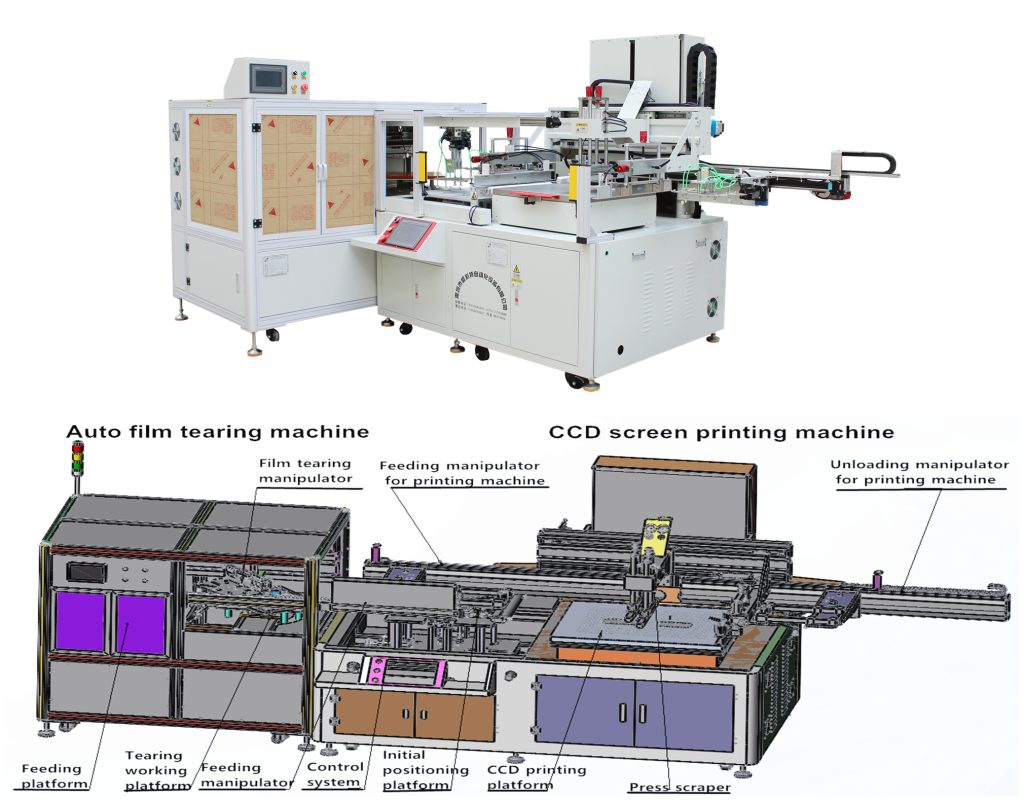

自動シートバイシートフィルム-ティアリングスクリーン印刷機

自動フィルム引き裂きCCDスクリーン印刷機アプリケーション :

この機械はFPCで広く使用されています,ペット, ポリ塩化ビニル, ラベルのバリエーション,転写紙 (映画), 床暖房フィルム, 地熱フィルム, 電熱フィルム, カラーペーパー, 映画, ネームプレート, フレキシブル回路基板, 携帯電話のキー, メンブレンスイッチ, 商標印刷, スクラッチカード, 粘着ステッカー, 紙, リボン, アルミホイルと銅箔このロール素材のシルクスクリーン印刷.

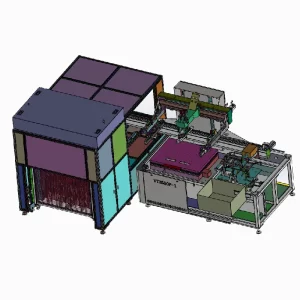

自動シートバイシートフィルム-ティアリングスクリーン印刷プリンター構造:

フィルム引き裂き付き自動整列印刷機 自動引き裂きフィルムセクションに分かれています , ローディングセクション, 荷降ろしセクション, 印刷セクションと右から左に移動するシャトルテーブル(テーブルを左から右に移動するためのオプション).

基板の手動ロード/アンロード用に設計されています; カメラがターゲット画像をキャプチャすると、ステージは自動的にオフセットし、その後、印刷のために印刷セクションに転送します.

画面フレームの上下の動き :サーボモーターとホールネジで駆動され、クリアランス公差は50umで制御されています.

自動シートバイシートフィルム-ティアリングスクリーン印刷機図

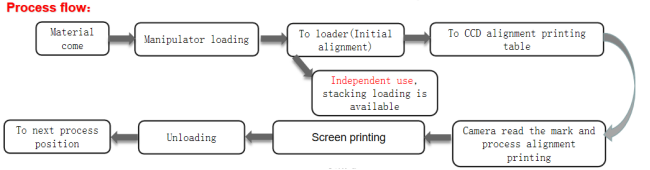

自動フィルム引き裂き高精度スクリーン印刷機の動作プロセス:

プロセス全体には以下が含まれます: 荷台での給餌.

引き裂くロボットがフィルムを送り、引き裂く.

供給ロボットが材料を供給します (引き裂かれた材料を初期位置決めプラットフォームに送ります).

材料は、初期位置決めのためにガイドを通過します.

ローディングロボットによるスクリーン印刷機のローディング.

CCDスクリーン印刷機アライメント印刷.

スクリーンプリンターピックアップロボットが材料をピックアップ.

自動シートバイシートフィルム-ティアリングスクリーン印刷装置の特徴:

フィルム引き裂き機

フィルム引き裂き機

1. 自動フィルム引き裂き機はマイコン制御を採用しています, サーボモーターが材料を引きずります, エッジを自動的に引き裂き、全自動生産を実現します.

2. 任意の固定長, ステップ長光電トラッキング, 正確で安定しています, ラベルが失われた場合の自動シャットダウン, そして

供給の光電制御.

3. 自動カウントとカウントアラームを設定可能.

ポジショニングプラットフォーム用供給マニピュレーター

位置決めプラットフォーム用供給マニピュレーター

シート保護フィルムがはがれた後, これは、この負圧マニピュレーターを介して初期位置決めプラットフォームに送られます. この時点でのマニピュレータは、フィルムを接続する機能を果たします- CCD印刷機への引き裂き. また、最初はコンピュータシステムの制御下に配置され、その後の印刷機によるピックアップと印刷を容易にします.

プリンター用自動真空装填装置

プリンター用自動真空装填装置

空気を送り込んで負圧を発生させる, グルーヘッドがシートを吸い上げ、メカニカルアームが繰り返し揺れてシートの貼り付きを防ぎます. その後、シートは印刷位置に正確に配置されます.

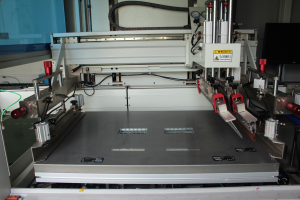

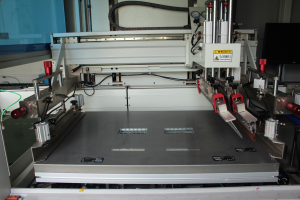

印刷テーブルと印刷ヘッド

印刷テーブルと印刷ヘッド

印刷プロセス中に空気を吸引する真空テーブル. 3 X-Y方向自動見当合わせ用センサ. サーボモーターによるプリントヘッドの水平移動. 走行部品用の高精度レールとベアリング. スキージドリップレスデザイン

自動乾式トンネル炉

自動乾式トンネル炉

印刷後, ロボットアームは、材料を乾式トンネル炉のコンベヤーベルトに自動的に降ろし、乾燥終了時にテールセクションから送り出されます. 乾燥後、印刷が完了するまで、シートは次の印刷層の印刷の準備が整います.

Vilityを選んだ理由

1. 私たちは工場であり、上記を持っています 10 研究および生産機械の長年の経験.

2. 私たちは経験豊富なRを所有しています&Dチーム.

3. アフターサービスも充実しています.

Q:あなたは製造所ですか、それとも貿易会社ですか?

VILITYはシンセン都市の有名なブランドの製造です, 広東省, 中国.

Q:私達の条件に従って特定の設計をすることができますか?

はい, 私達はあなたの条件に従って特別な変更をしてもいいです.

Q:あなたの支払い条件は何ですか?

50% deposit と 50% 配達前の残高, コピーに対するT/T 上陸の手形.

Q:あなたの会社の生産能力はどれくらいですか?

30 セット/月.

Q:どのような認定資格を持っていますか?

私達にセリウムがあります,ISO90001およびその他の認証.

Q:機器の保証期間はどのくらいですか?

マシン全体を1年間保証し、生涯にわたるソフトウェアアップグレードサービスを提供します.

Q:インストールおよびトレーニングサービスを提供していますか?

はい, 専門的なインストールおよびトレーニングマニュアルとビデオチュートリアルを提供します. また、操作をガイドするために、ライブビデオ会話も提供されます.

パッケージ:

自動ロールツーロールCCDアライメントスクリーン印刷機は、輸送前に厳格な安全性で梱包されます。上の図に示すように。輸送中に損傷が発生しないようにしてください.

印刷装置のサイズが大きく、質量が重いため, 通常、輸送には海上輸送または道路輸送を使用します. 海上輸送または中国-ヨーロッパ鉄道エクスプレスによる輸送を選択できます. 交易条件について, 通常、EXWを採用しています,FOB または CIF.

具体的な方法は、注文の連絡と確認の過程で確認できます.

引渡し時期:

3-20 注文確認後日数,細部の受渡し日はに従って決定されるべきである

生産時期と注文数量.

スクリ—ン印刷機

スクリ—ン印刷機