Automatic Sheet to Sheet High Precision Screen Printing Machine (with CCD Visual Positioning System) 紹介:

Sheet to Sheet High Precision Screen Printing Press/Sheet to Sheet High Precision Screen Printer/Sheet to Sheet High Precision Screen Printing Equippment

ヴィリティの CCD Alignment Screen Printing Machine for Sheet Material is the core machine of the sheet printing line.The whole process includes: 自動セパレート材料 – 自動ダスト除去 (クランプエッジの初期位置決めを含む) – 自動ローディング – CCDアライメントスクリーン印刷 – 自動アンロード – ベーキング/乾燥 – 完成品の自動収集.

automatic high precision screen printing machine for plastic, メタル, glass film and plate sheet

CCD Positioning Sheet to Sheet Screen Printing Machine Standard Operating Procedure:

原材料→自動供給機→自動印刷→自動UVまたはオーブン→自動受信→最終製品.

CCD Positioning Sheet to Sheet Screen Printing Press Application:

Vility’s Automatic Sheet to sheet CCD Alignment Screen Printing machine is perfect for printing electronics substrate material , such as graphic overlays, automotive dashboard, appliances panel, nameplates, flexible circuits, touch screen, aerospace label, diffuser, keyboard circuits, solar cell film,等.

高いアライメント精度, 印刷速度が速く、生産ライン全体を1人で操作できます.

関連

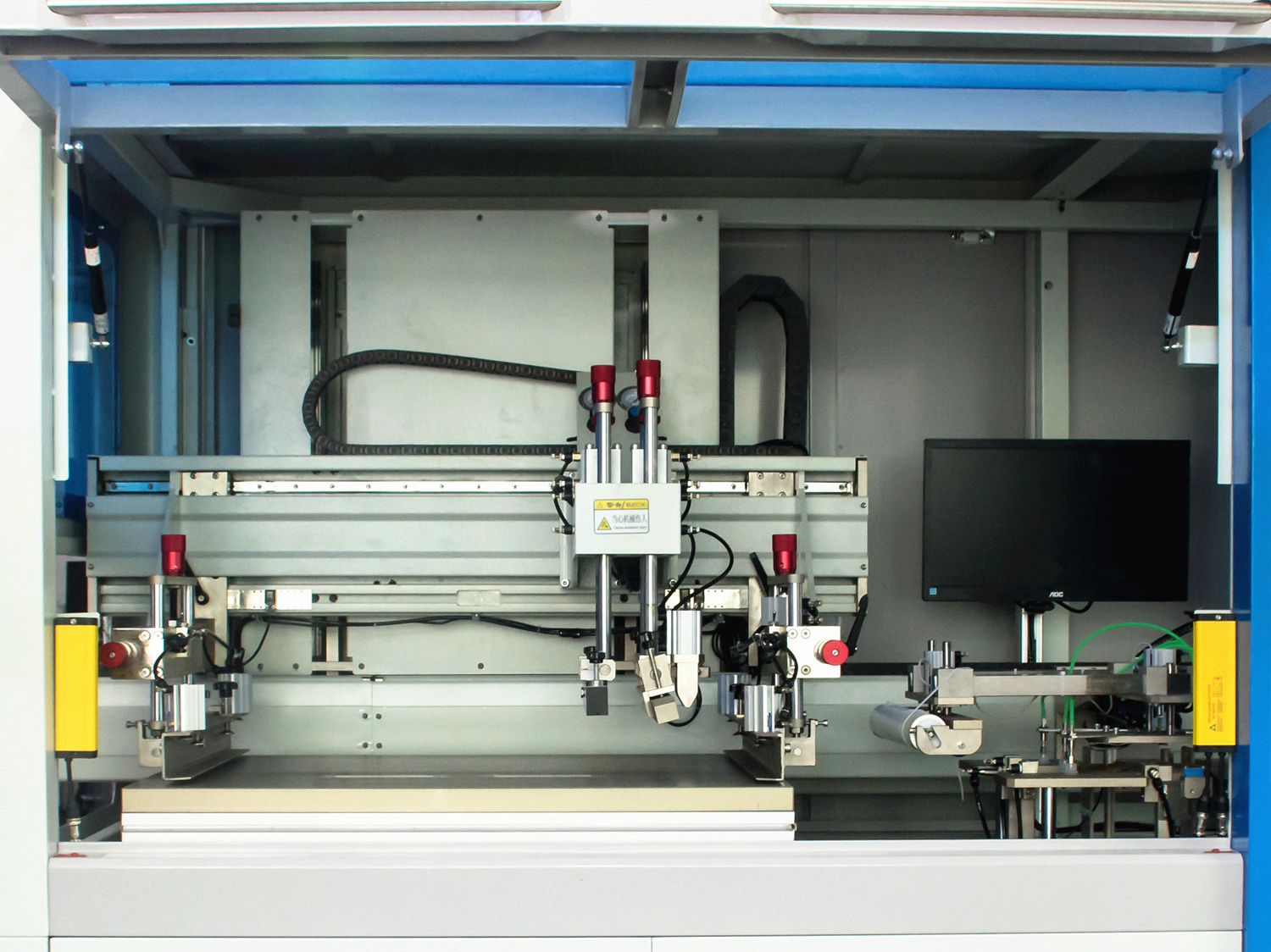

The CCD Alignment Screen Printing Presses for Sheet is Divided into loading section, 荷降ろしセクション, 印刷セクションと右から左に移動するシャトルテーブル(テーブルを左から右に移動するためのオプション). 基板の手動ロード/アンロード用に設計されています; カメラがターゲット画像をキャプチャすると、ステージは自動的にオフセットし、その後、印刷のために印刷セクションに転送します.

画面フレームの上下の動き :サーボモーターとホールネジで駆動され、クリアランス公差は50umで制御されています

Automatically separate material→auto removal→auto loading→CCD alignment screen printing→auto unloading →dry →auto collecting the finished product.

The CCD Alignment Screen Printing System for Sheet is widely used in FPC,ペット, ポリ塩化ビニル, 転写紙 (映画), 床暖房フィルム, 地熱フィルム, 電熱フィルム, カラーペーパー, 映画, ネームプレート, フレキシブル回路基板, 携帯電話のキー, 3 m glue, glue, フィルムスイッチ, 商標レーザー, スクラッチカード, 粘着ステッカー, 紙, リボン, aluminum foil and copper foil this sheet material silk screen printing.

Sheet Material Flatbed Screen Print Machine

Sheet to Sheet CCD Registration Screen Printing Machine Key Features and Performance:

(1). CCD automatic alignment system, if the similarity is not within the setting range, any abnormal, it will stop and automatically start adjust the alignment successful and continue to work.

(2). Using numerical control motor, 印刷速度, return to the ink speed can be set in a random block.

(3). Using numerical control motor, printing distance, return to the ink distance can be set in a random data.

(4). Automatic computing printing, and calculate the qty, and printing can be set automatically stop.

(5). Photoelectric control feeding and discharging to avoid the surface damage of substrates, can improve the printing quality.

Sheet Material Auto Vacuum Loader for Screen Printing

Automatic vacuum loading device

空気を送り込んで負圧を発生させる,the glue head sucks up the sheet and

the mechanical arm repeatedly shakes to prevent the sheet from sticking.

その後、シートは印刷位置に正確に配置されます.

Printing Table and Printing Head of Screen Printing Press

印刷テーブルと印刷ヘッド

Vaccum table with air suction during printing

過程.

3 sensors for automatic register in X-Y

directions.

Printing head horizontal movement by servo

motor.

High precision rails and bearings for running

parts.

スキージドリップレスデザイン

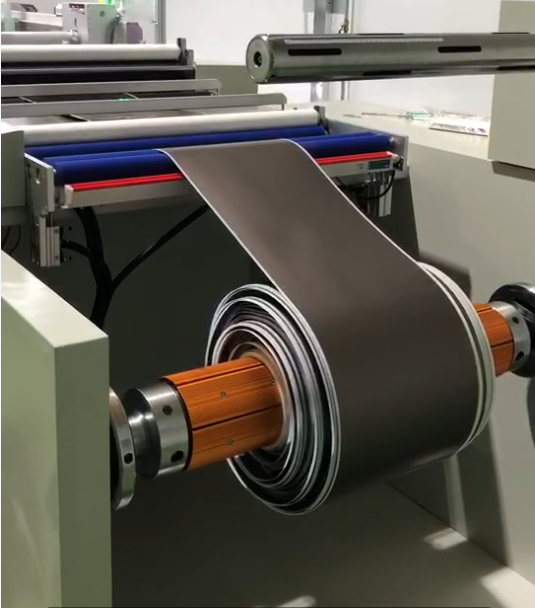

Industrial Automatic Drying Tunnels Furnace/Post Printing Equipment

自動乾式トンネル炉

印刷後, the robot arm automatically

unloads the material onto the conveyor belt of

the dry tunnel furnace and is sent out by the

tail section at the end of drying. After drying

the sheet is ready for the next layer of

printing until the printing is complete.

screen printing machine Main machine feature

(1)

Multicolor printing,

automatic photocell eye counterpoint,

computer control,

automatic detection color code,

if have any abnormal ,

it will stop automatic.

(2)

Using numerical control motor, 印刷速度,

return to the ink speed can be set in a random block.

(3) Using numericalcontrol motor, printing distance, return to the ink distance can be set in a random data.

(4)Automatic computing printing, andcalculate the qty, and printing can be set automatically stop.

(5)photoelectric control feeding and discharging to avoid thesurface damage of substrates, can improve the printing quality.

(6)Setting of printing speed and cycle run can be controlled via touch panel.

According to customers’ request, we accept customization, 例えば, adding anti-dust cover, exhuast cover, drying oven, tunnel furnace, UV curing machine, feeding direction, loading and unloading direction, 等.

The max feeding frame size is 400mmx500mm(カスタマイズ可能), it can be adjustable after putting material on to fix them, right side, front and back sides are adjustable, it’s convenient for customer to make adjustment.

The advantage of this machine is printing platform automatic alignment with CCD camera positioning, it’s very suitable for printing multicolors which need high precision, the accuracy of camera positioning is ± 0.02mm, printing accuracy is ± 0.05mm, it can give customers a superior performance, and greatly improved production yield.

The printing scraper and blade adopt imported high level quality stainless steel, expanding printing usinglife, it has a pressure stabilizer ensuring constant pressure at all times.There’s a function that the height and oblique can be adjustable to improve printing quality.

All raw material we adopt high quality stainless steel, beautiful and longlife using.

User-friendly PC based control combined with touch screen monitor for maximum operational convenience.

デフォルトの言語は中国語-英語です, お客様は、, 他の言語のカスタマイズも受け付けています.

アフターサービス

* 終生

* 予備部品

* ビデオによる技術サポートとオンラインサポート

* 現場でのメンテナンスおよび修理サービス

* エンジニアは機械類を海外に整備するために利用できます.

関連

Q: あなたは工場ですか、それとも商社ですか?

ある: 私たちは包装機を製造する工場であり、完璧なOEMおよびアフターサービスを提供しています.

Q: 機械がどのように機能するかを示すビデオを送ってもらえますか?

ある: たしかに, すべてのマシンのビデオを作成し、Youtubeにアップロードしました.

Q: どうすればあなたのマシンがうまく機能することを知ることができますか?

ある: 納品前, 私達はあなたのための機械作動状態をテストします.

Q: あなたのマシンが私の製品用に設計されていることをどのように知ることができますか?

ある: 製品のサンプルをお送りいただければ、機械でテストします.

Q: 注文の支払い方法?

ある: 私達はT/Tを受け入れます, ウエスタンユニオンの支払方法. 500米ドル未満の注文の場合, 支払いにPayPalを受け入れます.Q: CE証明書はありますか?

ある: 機械のあらゆるモデルに対応, CE証明書があります.

関連

スクリーン印刷装置はウッドプライケースに梱包されます( 海上輸送の輸出基準 )輸送前。下図のように。輸送中に損傷が発生しないようにしてください.

印刷装置のサイズが大きく、質量が重いため, 通常、輸送には海上輸送または道路輸送を使用します. 海上輸送または中国-ヨーロッパ鉄道エクスプレスによる輸送を選択できます. 交易条件について, 通常、EXWを採用しています,FOB または CIF.

具体的な方法は、注文の連絡と確認の過程で確認できます。.

関連