Semi-Auto Single Head Guide Hole Drilling Machine

CCD Automatic Guide Hole Drilling Machine/High Precision Hole Drilling Machine/CCD – Camera Controlled Drilling Machine/CCD Target Precision Drill Machine

CCD Automatic target hole drilling machine is also known as automatic target drilling machine, CNC drilling machine, automatic positioning drilling machine, different names, but actually the same kind of equipment .

High Accuracy Single Head Semi-Auto CCD Guide Hole Drilling Machine for Single PCB Board

Guide Hole Drilling Equipment Application

Vility automatic hole drilling machines applied in printing and packaging, electronic printing, nameplate signs and other industries post-printing alignment drilling!

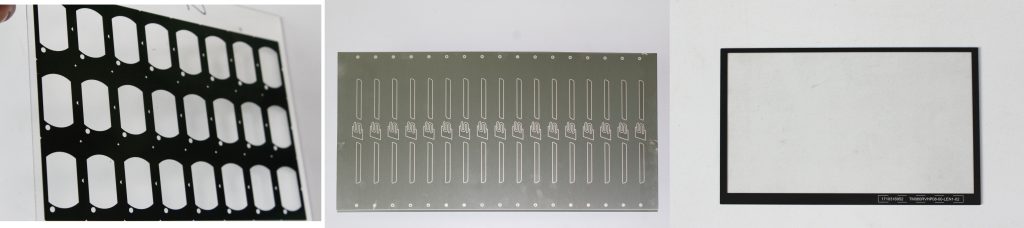

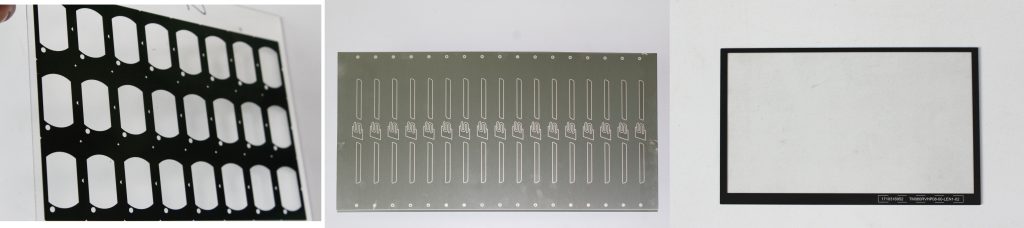

Guide Hole Drilling Equipment Drilled Samples

The hole drilling equipment is used in PCB circuit board, FPC soft board, IMD/IML, film, diazo sheet, cell phone panel, cell phone keypad, sticker, membrane switch, film, PE, PC, PVC, PET film, polyester film, thin aluminum, aluminum substrate, FR4 glass fiber board and many other materials.

CCD automatic sheet postion hole drilling machine is suitable for single and double panel, PCB multi-layer board, fiberglass, PVC panel, acrylic and other fragile plastic sheet positioning drilling.

Semi-Auto Single Head Guide Hole Drilling Machine features

- Function: Sheet is all OK; CCD fully automatic positioning drilling.

- High accuracy, overall error less than or equal to 0.015mm.

- Fast drilling speed, the average drilling speed is 7-8 times faster than manual drilling speed, only 0.5 seconds per hole.

- No material dragging, accurate positioning of icons and automatic drilling.

- Flexible materials and fragile materials such as acrylic sheets can be drilledby the machine without damaging the material. Fast speed, software can be upgraded free of charge for life.

- Computerised working system, human-machine interface, direct working mode setting on the touch screen, simple and intuitive.

- Special light source identification method, can automatically identify the round figure on various materials, automatic alignment drilling.

- Drilling can be viewed directly on the 8″ computer screen or at the drilling station, respectively.

- The presser foot on the machine flattens the film to be drilledduring drilling, making it more accurate.

- Specialised settings are available. The computer system can be upgraded and provides you with a strong professional technical support.

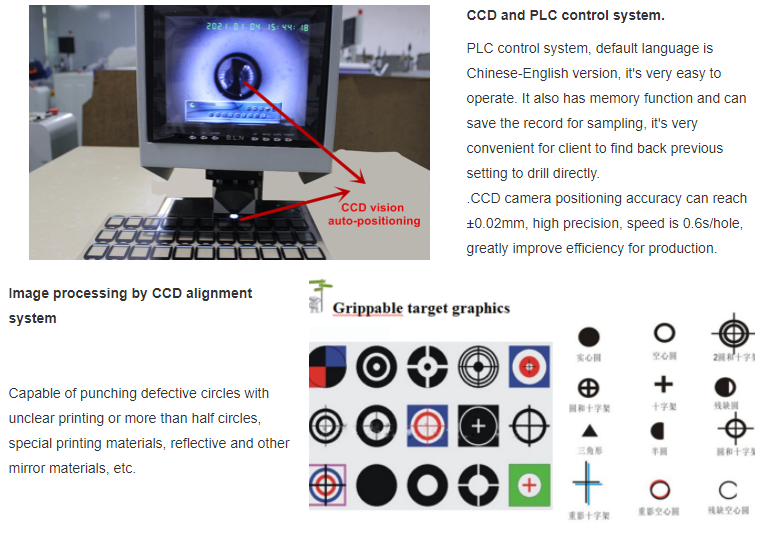

- Image processing: 2-value integrated image processing method.

- Capable of drilling defective circles with unclear printing or more than half circles, special printing materials, reflective and other mirror materials, etc.

Semi-Automatic Target Driller Structurer:

Device configuration:

| Linear guide |

Taiwan HIWIN |

| Pulling material motor |

Chine Leadshine servo motor + type heart reducer |

| CCD 5 million pixels |

Quaternion numerical control |

| Photoelectric switch |

Japan Omron |

| Bearing |

Japan NSK |

| Cylinder solenoid valve |

Taiwan SHAKO |

| Ball screw |

TBI |

| Mould |

Shenzhen Vility |

Guide Hole Drilling Machine Alignment XYθ platform

This equipment mainly includes hole drilling unit, equipped with CCD moving platform , high precision XYθ alignment platform, stable alignment, human-machine interface control + button switch, can set a variety of functional parameters, easy to operate; CCD automatic positioning punching, can automatically adjust the field of view of CCD according to the size of the material.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic hole drilling .

1.Alignment XYθ platform: Alignment XYθ platform is the core part of the machine, used for CCD vision alignment, this alignment platform is composed of XYθ4 axes, with alignment eccentricity function, alignment accuracy can be controlled within 0.02mm.

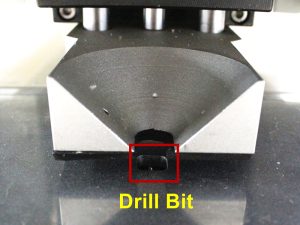

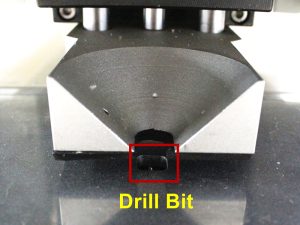

Hole Drilling Machine Drill Bit

High Precision hole positioning

There’s up and down light button, in order to make enough light for camera to identify mark point to drill hole in precision. The blow function is to blow the scrap after drilling, it can keep drilling smoothly all the time.

Semi-Auto Guide Hole Drilling Machine Hole Drilling

Preser foot

Drilling can be viewed directly on the 8″ computer screen or at the drilling station, respectively.

The presser foot on the machine flattens the film to be drilled during drilling, making it more accurate.

CCD and PLC control system.

PLC control system, default language is Chinese-English version, it’s very easy to operate. It also has memory function and can save the record for sampling, it’s very convenient for client to find back previous setting to drill directly. .CCD camera positioning accuracy can reach ±0.02mm, high precision, speed is 0.6s/hole, greatly improve efficiency for production.

FAQ :

Q: Are you manufactory or trade company?

A: VILITY is a famous brand manufacture of Shenzhen City, Guangdong Province, China.

Q: Can you make particular design according to our requirements?

A: Yes, we can make a special change according to your requirements.

Q: What are your payment terms?

A : 50% deposit and 50% balance before delivery, T/T against copy of Bill of Landing.

Q: What is your company’s production capacity?

A:30 Sets/ Month.

PACKAGE:

Vility Industry Machine will be packed in strict safety before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the machinery, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen printing machine

Screen printing machine