Automatic Edge-Alignment Sheet High Precision Screen Printing Machine Introduction:

Sheet to Sheet Edge-Alignment Screen Printing Press/Sheet to Sheet Edge-Alignment Screen Printer/Sheet to Sheet Edge-Alignment Screen Printing Equippment

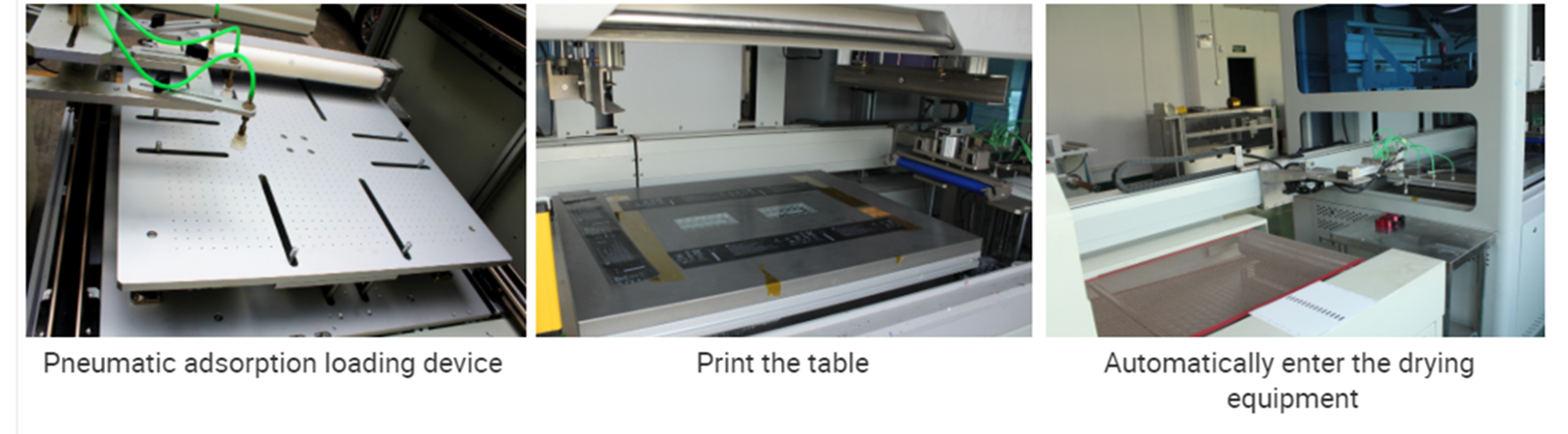

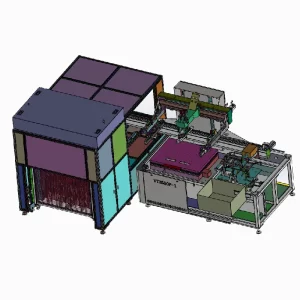

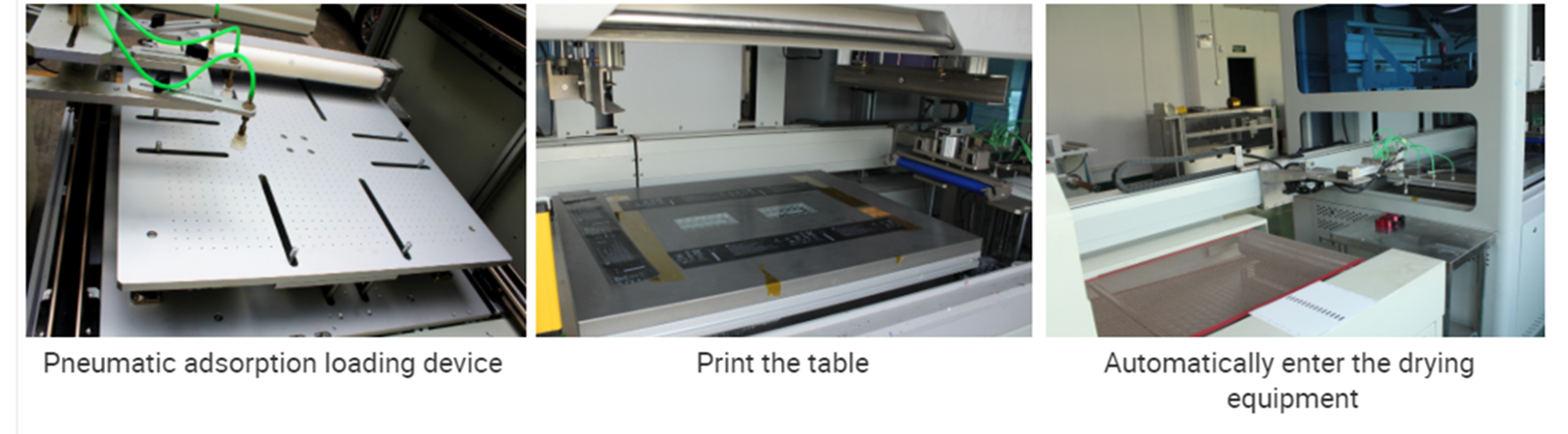

Vility’s Edge-Alignment Screen Printing Machine for Sheet Material is the core machine of the sheet printing line.The whole process includes: automatic separate material – auto dust removal (including Initial positioning of clamping edge) – automatic loading – CCD alignment screen printing – automatic unloading – baking/drying – auto collecting the finished product.

Automatic Edge-Alignment Screen Printing Machine for Sheet Material

Sheet to Sheet Edge-Alignment Screen Printing Equipment Standard Operating Procedure:

Raw material →Automatic feeding machine →Automatic printing→Automatic UV or oven →Automatic receiving →End product.

Sheet to Sheet Edge-Alignment Screen Printing Press Application:

Vility’s Automatic Sheet to sheet CCD Alignment Screen Printing Machine is suitable for printing on sheet materials such as: PCB circuit board, PC composite board,membrane switches, glass covers, acrylic sheet, PET sheet, mobile phone panel, Nameplate, Intelligent Cards, Automotive dashboard/speedometer,ITO, conductive films, composite back covers and other thick substrate.

High alignment accuracy, fast printing speed and the entire production line can be operated by just one person.

Sheet to Sheet Edge-Alignment Screen Printing Machine VT4060P-KB Features

1.Brief introduction to the operation action of dividing feeding/printing/unloading robot:

1) Adjust the position of the stopper, and separate the first sheet from the following one by the suction cup and air nozzle of the pick-up robot, to be picked up by the feeding robot arm.

2) Under the action of feeding robot arm and air nozzle, the sheet is separated and sent to the card edge alignment platform.

3) The sheet edge alignment printer will perform edge alignment according to the material position, and after the alignment is completed, the printer will screen print;

After printing, the material is lifted up by the ejector pin under the printing table. After the material is dragged by the suction cup of the feeding robot, the vacuum is opened and the material is sucked up and sent to the conveyor line, and then the material is sent to the tunnel furnace by the conveyor line.

2.The function and composition of the dividing and loading robot.

| NO. |

Module |

Function |

Main components |

| 1 |

Electric control part |

Fast, stable and continuous operation. |

Panasonic Servo |

| 2 |

Lifting platform assembly |

Ensure the material is at the same height when picking up. |

Motors, linear bearings, screws |

| 3 |

Points of material components |

Separate the top and bottom pieces of material. |

pneumatic cylinder, suction cup, air nozzle |

| 4 |

Feeding component |

Feeding the material into the screen printing machine. |

servo motor, guide rail, timing wheel, timing belt |

| 5 |

Suction jigs |

Ensures no wrinkling of the material when clamping. |

Acrylic plates, aluminum parts, vacuum suction cups |

- Technical standards for robotic arms.

| NO. |

Item |

Standards |

| 1 |

Number of axes |

Loading robot arm (single axis), feeding robot arm (two axes) |

| 2 |

Robotic arm movement mode |

Servo motor + linear guide + timing belt |

| 3 |

Feeding stroke |

1400mm |

| 4 |

Lowering stroke |

1600 mm, short arm 1600 mm,long arm 2100 mm |

| 5 |

Two-axis stacking method |

Y-axis first and then Z-axis on Y-axis, Z-axis with fixture set |

| 6 |

Repeat position accuracy |

±2.5mm. |

| 7 |

Speed |

500-650pcs/h |

- Fixture technical standards: Suction plate fixture type can be customized according to product characteristics.

| NO. |

Item |

Standards |

| 1 |

Suction plate structure |

The top is stainless steel plate and the bottom is aluminum plate. |

| 2 |

Suction cup material |

AL6061+304 |

| 3 |

Air source |

Supplied with 400w blower |

| 4 |

Material size range |

380*500-200*350mm |

| 5 |

Thickness of material |

0.05mm-2.0mm |

| 6 |

Dividing method |

Adopt whole sheet detachment, overall shaking after removing static electricity, and multi-sheet inspection after dividing material |

After-Sales Service

* Lifelong

* Spare parts

* Video technical and online support

* Field maintenance and repair service

* Engineers are available to service machinery overseas.

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, Western Union paying methods. For those orders less than 500USD, we accept PayPal to pay.Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

The screen printing equipment will be packed in woodply case( sea shipping export standard )before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order..

Screen printing machine

Screen printing machine