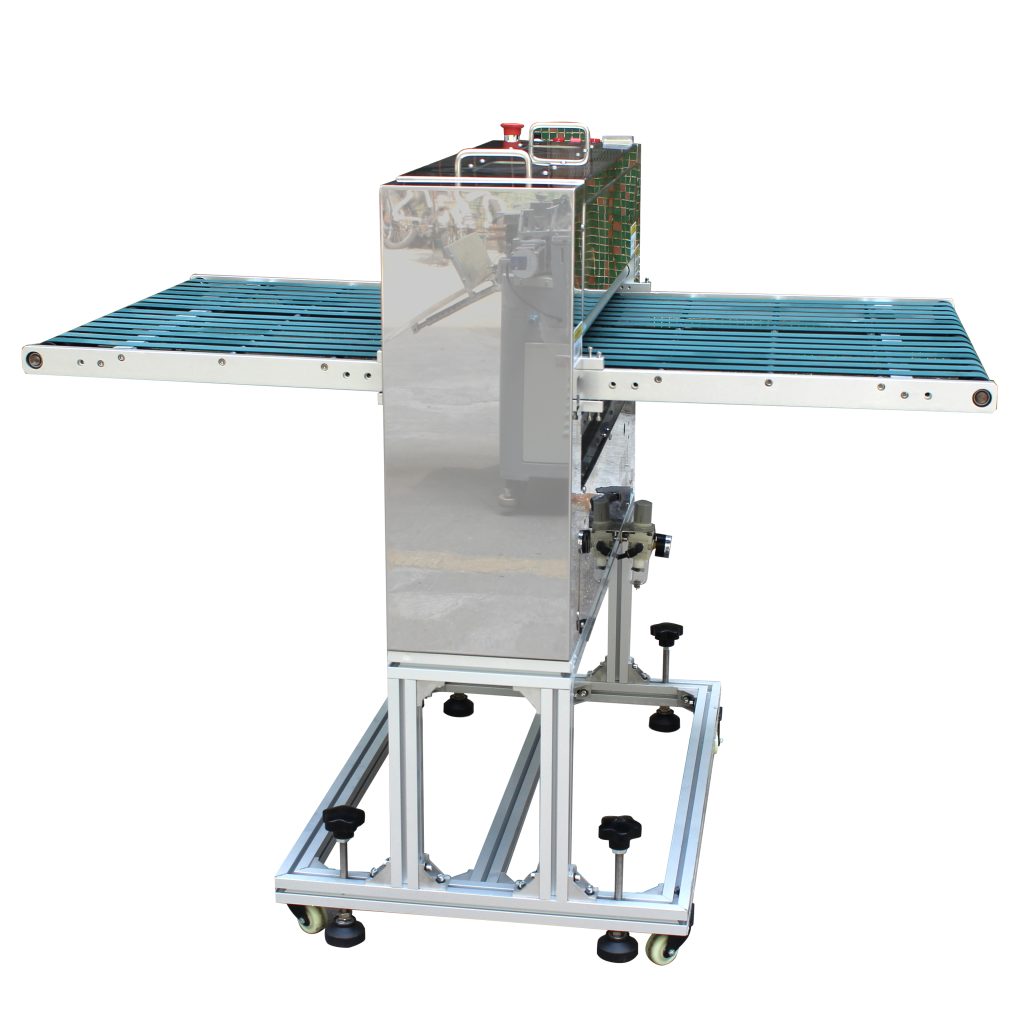

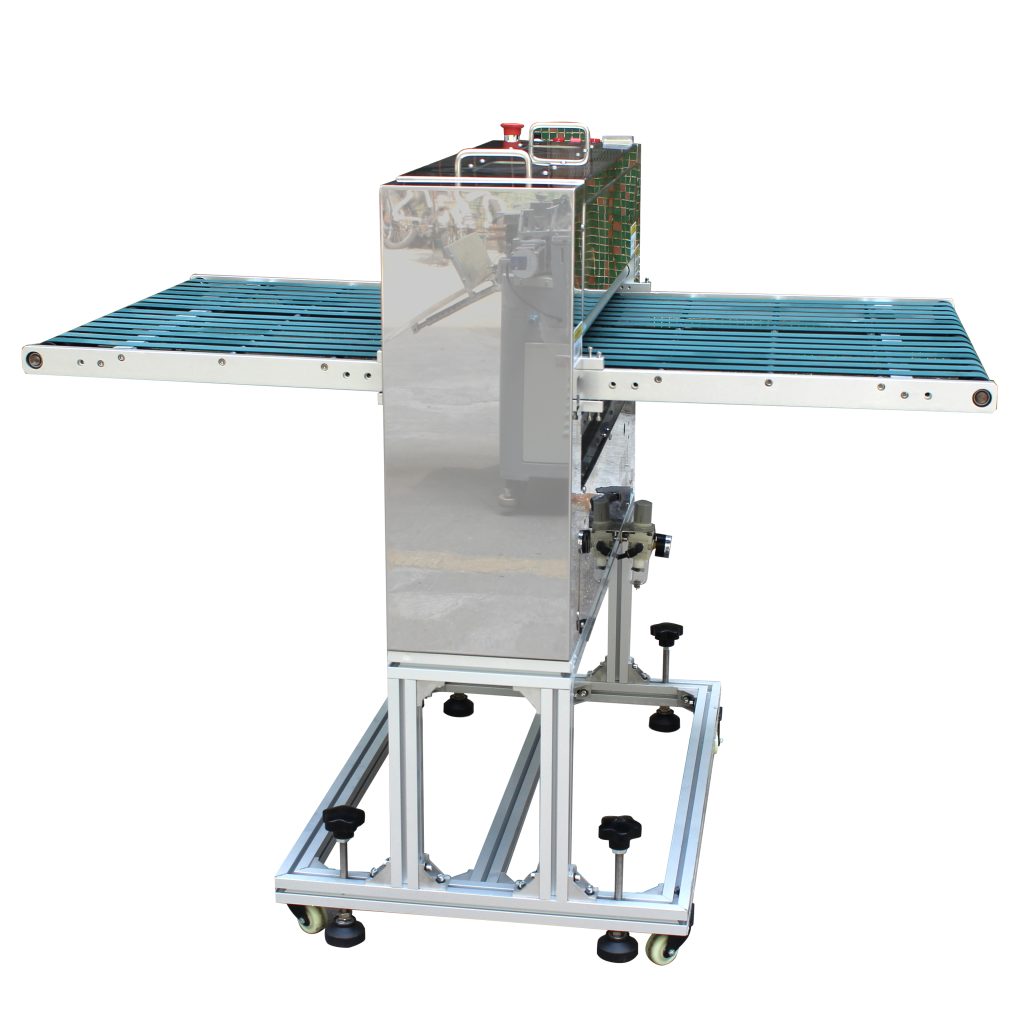

Electrostatic Dust Removal Machine Description:

Electrostatic Precipitators/Dust Removal Machine/Dust Cleaning Machine/Electrostatic Dust Remover/Sheet Cleaning Machine/Electrostatic Cleaning Equipment

Double-sided double cleaning, eliminate electrostatic, and automatically separate the sticky paper. One-way continuous operation, one-way automatic electric eye induction operation, automatic reciprocating electric eye induction operation, two-way double-sided cleaning, suitable for both automatic production line and individual stand-alone operation. After the material enters the machine, the electrostatic accumulated on the surface of the material is removed by two high-efficiency high-voltage static bars. Two dust removing rollers are used to remove the dust on the surface of the material, and the dust collecting roller transfers the dust to the collecting roller by the rotation of the dust removing roller. This roller can be cleaned with soapy water and used repeatedly.

Electrostatic Dust Removal Machine Applications:

Printed circuit boards, flexible circuit boards, copper foil ,film , ceramic substrates, film with different thickness of base plate in the printing, stickers, press, drilling, slitting, cutting, inspection and some other working plate surface clean;

Optic monitor: TFT – LCD, the STN, TN, LCD, touch panel, polaroid, light module, reflection film, diffusion film, light panels, optical acrylic, glass, such as base material, coating, laminating, printing, assembly, inspection and other work surface clean;

Precision screen printing: PC, PP, PE, PET, PMMA, PVA, trademarks, trademarks, laser stickers, from type paper cutting, coating, stick cloth, clean to the board face film, printing, etc.

Tags: Dust Cleaning Machine,Thin film dust machine, Film dust cleaning machine, Electrostatic Precipitator for Soft Plate Substrate, Diaphragm cleaner, Diaphragm dust collector, Light guide plate electrostatic precipitator, PET Film Electrostatic Precipitator, Dust sticky machine, Plate cleaner, Glass dust sticker, Plate cleaner, electrostatic dust removal machine, electrostatic cleaner, Electrostatic precipitator, electrostatic dust precipitator

Electrostatic Dust Removal Machine Features:

Our electrostatic precipitator has stable operation, low failure rate, and easy operation. Upper and lower independent drawer cleaning method, easy to clean and maintain. Operation mode can be selected by yourself. Double-sided cleaning at the same time. Design number alarm function. Working environment: temperature <50 degrees Celsius.

1. Drawer-type device, cutting and replacement more convenient, it can be produced in line and equipped with a transmission wheel set.

2.Automatic feed, automatic return, feed and return transfer options are available in a variety of transfer modes.

3. Super ability to remove electrostatic and dust, no folding angle, no scratch on the surface of rolled plate. The corresponding value can be set according to the cleanness of the material, and the alarm prompt can be given after reaching the value to replace the dust collecting roll paper in time to ensure the cleanness of the material.

Vility Advantages

1.Accept OEM/ODM, screen printing industry turkey solution line customization.

2.We provide a one-stop service integrating design, measurement, production, delivery, installation, and after-sales service.

3.We have 13 years of experience in product development and production. Professional engineer team can quickly design products according to your requirements.

4.We have always followed the standardization rules for a rigorous production process, saving time and cost for both parties and bringing maximum benefits to you.

About VILITY

Shenzhen VILITY Automatic Machinery Co.,Ltd established in 2010 year, located in Shenzhen city, China. Our company’s development approach is : People-oriented, Technological innovation , service-oriented. VILITY is a combine-word, comes from Victory& Ability and Victory &Quality which means we always pursue high quality and good service to meet customers requirements and high competitive market. We believe: Service first, customers supreme. VILITY is a Professional manufacturer, providing ONE-STOP SOLUTION for intelligent printing industry. Recent years, We have pay most of the techniques and technologies to implement Industry 4.0 Robotic. VILITY has been successfully Provide unmanned production lines for many customers. Therefore, it is honored to get a high degree of social affirmation. Our main products are CCD automation alignment machines which included in: CCD guide hole punching machine, CCD screen printing machine, CCD die cutting machine, CCD Fitting machine, Automation CCD testing machine for screen printing, Hardware, plastics and other industries. Those machines suit for both flat material and roll to roll material. With substantial ongoing investment in research and development, VILITY is ideally positioned to continue doing high precision CCD robotic machines for both the commercial and domestic markets. We are looking forward to establishing well long –term business relationship with you and your esteemed companies.

Q:Are you manufactory or trade company?

VILITY is a famous brand manufacture of Shenzhen City, Guangdong Province, China.

Q:Can you make particular design according to our requirements?

Yes, we can make a special change according to your requirements.

Q:What are your payment terms?

50% deposit and 50% balance before delivery, T/T against copy ofBill of Landing.

Q:What is your company’s production capacity?

30 Sets/ Month.

Q:What certifications do you have?

We have CE,ISO90001 and other certifications.

Q:What is the warranty period for your equipment?

We guarantee the whole machine for one year and provide life-long software upgrade service.

Q:Do you provide installation and training services?

Yes, we will provide you with professional installation and training manuals and video tutorials. Live video conversations will also be provided to guide you through the operation.

PACKAGE:

The Automatic machine will be packed in strict safety before transportation.As shown in the figure above.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen printing machine

Screen printing machine