Automatic Sheet by Sheet High Precision Film-Tearing Screen Printing Machine Description

Automatic Sheet by Sheet Film-Tearing Screen Printing Equipment/Automatic Sheet by Sheet Film-Tearing Screen Printing Printer/Automatic Sheet by Sheet Film-Tearing Screen Press

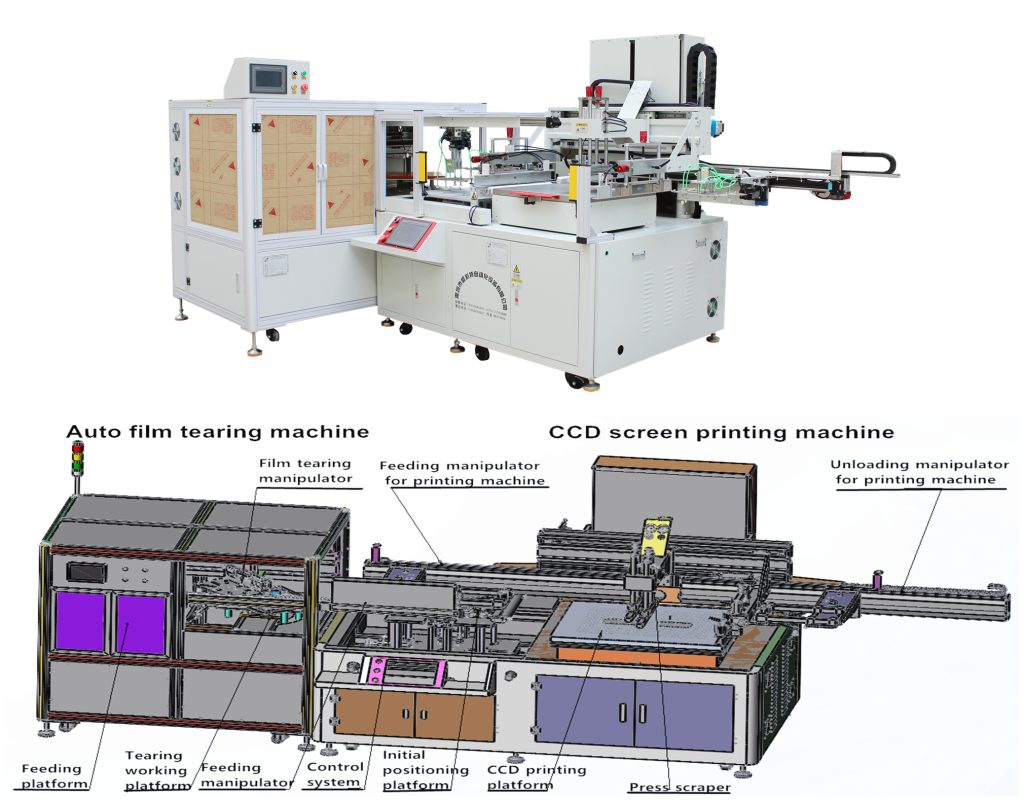

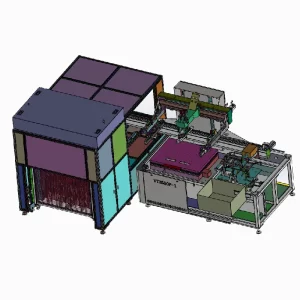

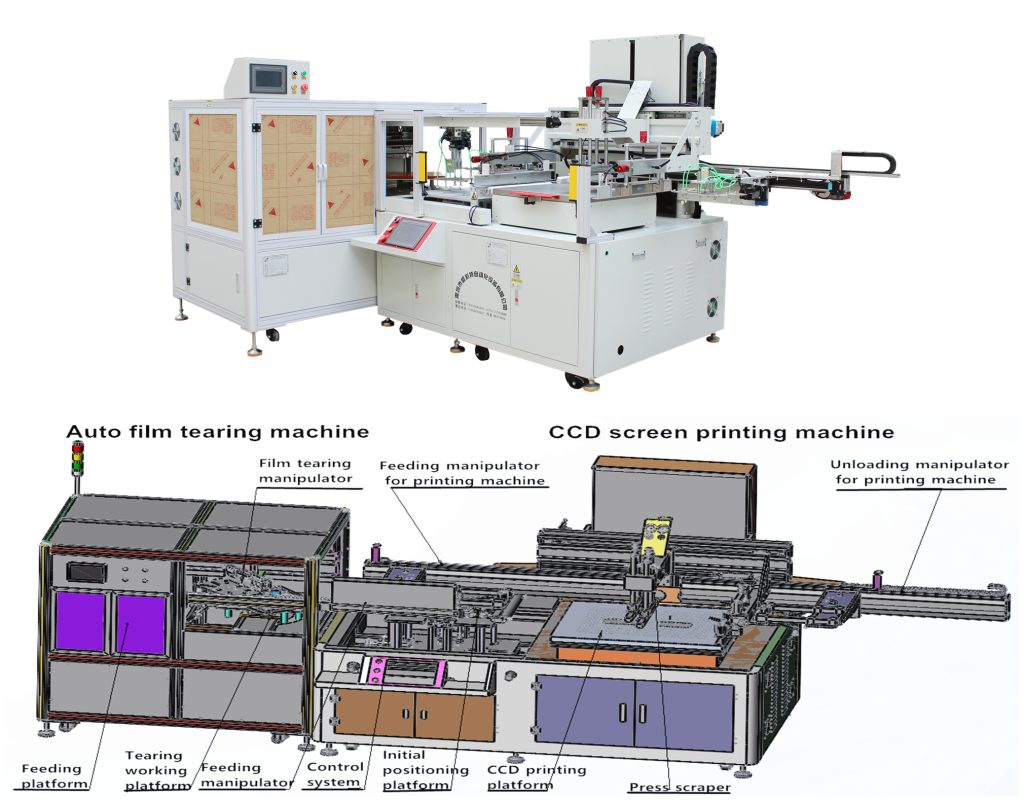

The Automatic alignment printing machine with film tearing machine is the addition of an automatic film tearer to the conventional CCD printing machine. It is used for precision materials where the protective film of the sheet needs to be removed before printing.

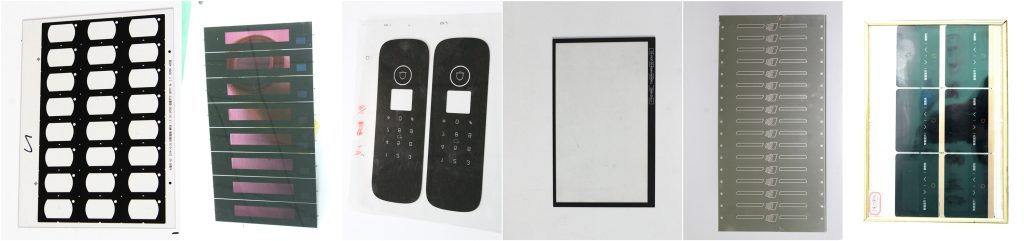

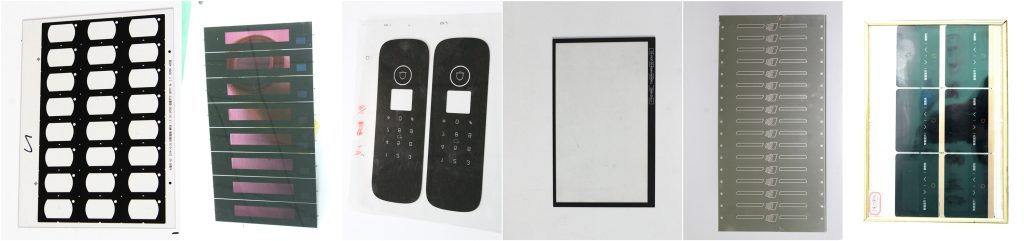

The Automatic alignment printing machine with film tearing is suitable for printing on sheet materials such as: membrane switches, glass covers, acrylic, ITO, conductive films, composite back covers, etc.

High alignment accuracy, fast printing speed and the entire production line can be operated by just one person.

Automatic Sheet by Sheet Film-Tearing Screen Printing Machine

Automatic Film-tearing CCD Screen Printing Machine Application :

This machine is widely used in FPC,PET, PVC, varies of label,transfer paper (film), floor heating film, geothermal film, electro thermal film, color paper, film, name plate, flexible circuit board, mobile phone keys, Membrane switch, trademark printing, scratch CARDS, self-adhesive stickers, paper, ribbon, aluminum foil and copper foil this roll material silk screen printing.

Automatic Sheet by Sheet Film-Tearing Screen Printing Printer Structure:

Automatic alignment printing machine with film tearing Divided into automatic tear film section , loading section, unloading section, printing section along with a shuttle table that moves from right to left(optional for printing table to move from left to right).

Designed for manual loading /unloading of substrate; once the camera captures the target image the stage auto offsets and subsequently transports to printing section for printing.

Screen frame up/down movement :driven by servo motor and hall screw with clearance tolerance controlled with 50um.

Automatic Sheet by Sheet Film-Tearing Screen Printing Machine Diagram

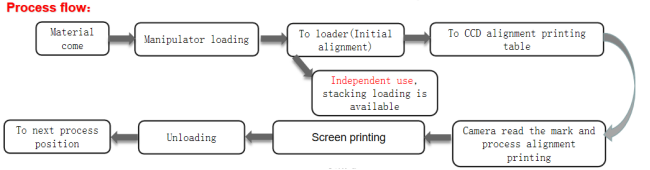

Automatic Film-Tearing High Precision Screen Printing Press Operating Process:

The whole process includes: Feeding on the loading platform.

Tearing robot feeds and tears the film.

Feeding robot feeds the material (delivers the torn material to the initial positioning platform).

The material passes through the guides for initial positioning.

Loading of the screen printing machine by the loading robot.

CCD screen printing machine alignment printing.

Screen printer pick-up robot picks up the material.

Automatic Sheet by Sheet Film-Tearing Screen Printing Equipment Features:

film tearing machine

film tearing machine

1. The auto film tearing machine adopts microcomputer control, servo motor drags the material, and automatically tears the edge to realize fully automatic production.

2. Arbitrary fixed length, step length photoelectric tracking, accurate and stable, automatic shutdown when label is lost, and

photoelectric control of feeding.

3. Automatic counting and counting alarm can be set.

feeding manipulator for positioning platform

Feeding manipulator for positioning platform

After the sheet protection film has been torn off, it is sent to the initial positioning platform via this negative pressure manipulator. The manipulator at this point serves the function of connecting the film- tearing to the CCD printing machine. It is also initially positioned under the control of the computer system to facilitate the subsequent pick-up and printing by the printing machine.

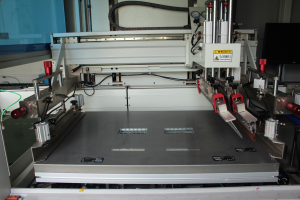

Automatic vacuum loading device for printer

Automatic vacuum loading device for printer

By pumping air to create negative pressure, the glue head sucks up the sheet and the mechanical arm repeatedly shakes to prevent the sheet from sticking. The sheet is then placed precisely in the printing position.

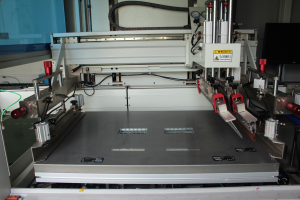

Printing Table and Printing Head

Printing Table and Printing Head

Vaccum table with air suction during printing process. 3 sensors for automatic register in X-Y directions. Printing head horizontal movement by servo motor. High precision rails and bearings for running parts. Squeegee dripless design

Automatic dry tunnel furnace

Automatic dry tunnel furnace

After printing, the robot arm automatically unloads the material onto the conveyor belt of the dry tunnel furnace and is sent out by the tail section at the end of drying. After drying the sheet is ready for the next layer of printing until the printing is complete.

The reason for choosing Vility

1. We are Factory and have above 10 years experiences for research and production machines.

2. We own experienced R&D teams.

3. We can supply fully after-sales service.

Q:Are you manufactory or trade company?

VILITY is a famous brand manufacture of Shenzhen City, Guangdong Province, China.

Q:Can you make particular design according to our requirements?

Yes, we can make a special change according to your requirements.

Q:What are your payment terms?

50% deposit and 50% balance before delivery, T/T against copy ofBill of Landing.

Q:What is your company’s production capacity?

30 Sets/ Month.

Q:What certifications do you have?

We have CE,ISO90001 and other certifications.

Q:What is the warranty period for your equipment?

We guarantee the whole machine for one year and provide life-long software upgrade service.

Q:Do you provide installation and training services?

Yes, we will provide you with professional installation and training manuals and video tutorials. Live video conversations will also be provided to guide you through the operation.

PACKAGE:

The Automatic Roll to Roll CCD alignment screen printing machine will be packed in strict safety before transportation.As shown in the figure above.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen Printing Machine Packing

Screen printing machine

Screen printing machine