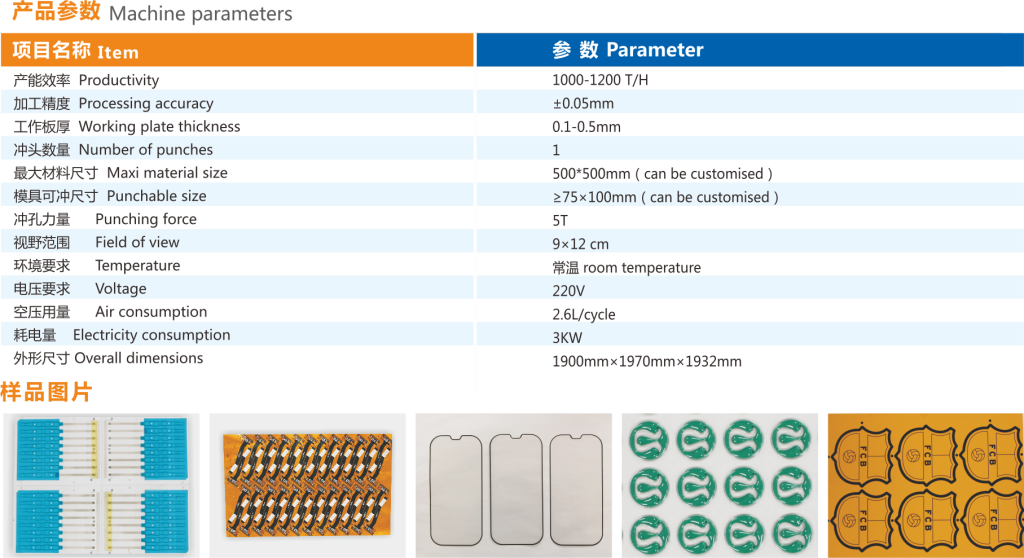

Small Type CCD Vision Hole Punching/Die Cuttign Machine Description

This equipment is an automatic shaped punching equipment designed to improve the production efficiency and product quality based on the punching processing field. It is characterized by CCD high precision positioning platform positioning and cam rotary drive punching and forming to improve product production efficiency and product quality.

Composition:CCD high precision positioning platform mechanism; CAM punch cutting mechanism; Pressing mechanism

Small Type CCD Vision Hole Punching/Die Cuttign Machine

Small High Precision Hole Puncher/Die Cuter Application & Specifications

Apply for: FPC, PET, 3M adhesive, conductive film, IMD, appliance panel, flate cable labels, nameplates and so one

Punching positioning hole is not needed, automaticall move to punch according to the coordinates set, this machie is perfect for small size sheet, which integrate hole punching and die cutting , more efficient and safer! one person can handle sevel machines

CCD Automatic target hole punchine machine is also known as automatic target punching machine, CNC punching machine, automatic positioning punching machine, different names, but actually the same kind of equipment .widely used in printing and packaging, electronic printing, nameplate signs and other industries post-printing alignment hole punching!

The equipment is used in PCB circuit board, FPC soft board, IMD/IML, film, diazo sheet, cell phone panel, cell phone keypad, sticker, membrane switch, film, PE, PC, PVC, PET film, polyester film, thin aluminum, aluminum substrate, FR4 glass fiber board and many other materials. CCD automatic hole drilling machine is suitable for single and double panel, PCB multi-layer board, fiberglass, PVC panel, acrylic and other fragile plastic sheet positioning drilling.

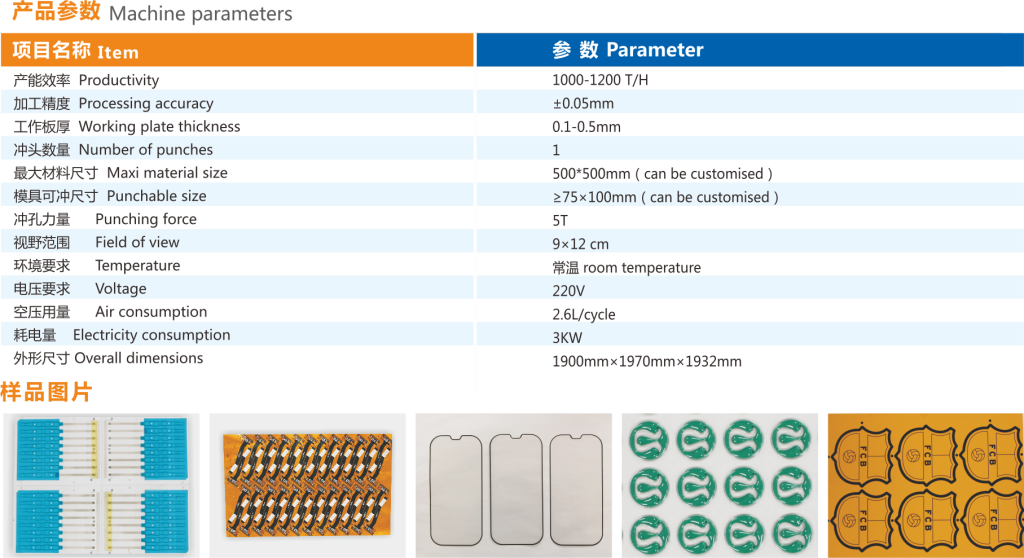

CCD Automatic target die cutting machine

widely used in all kinds of trademarks, labels, cell phone keys, cell phone panels, conductive film, membrane switches, film, IMD/IML, FPC flexible circuit boards, PET/PVC/PC/PP and other flexible coil positioning hole punching and roll material slicing.

Automatic CCD Guide Hole Drilling Machine Features

1.Suitable for drilling positioning holes of pcb rigid circuit boards, pvc/pet, plexiglass, acrylic, mp3/4, imd, mobile phone chips, etc. ■

2.Fast speed and high precision:

3. ccd image intelligent recognition processing system, full-screen automatic tracking technology, automatic target search, lock, automatic perforation without pedaling, the whole process only takes 0.4 seconds. After drilling, it has the function of rejecting heavy drilling, which is easy to operate, easy and fast, and has high output.

4.The automatic tracking program has the function of predicting the accuracy of the perforation center and correcting the deviation, and its accuracy is guaranteed to be less than 0.010mm.

5.Identification function:

.A variety of image calculation methods can effectively identify circles, rings, crosses, split rings, etc., and can ensure that the center accuracy remains unchanged when the target is incomplete or deformed.

6.Auto login function:

.The newly added automatic recognition function When entering a new target shape, you only need to click once on the target shape to complete the new target shape registration. The whole process only takes 3 seconds to complete, and the program automatically completes the radius, cross line, etc. Automatic measurement of parameters.

7.Advantage accessories:

. Equipped with intermittent vacuum cleaner, the system program automatically controls chip removal, reducing the working environment.

.Selected high-quality electric drill, no need for water circulation cooling; the drilling speed and height are adjustable, and the electric drill speed is 30000-60000 rpm.

8.Operation interface:

English operation interface, Chinese prompts will appear when the mouse moves. Each operation can be completed with a single click of the mouse and requires no training. There is also a touch screen option for purchase.

Our company is a representative of high-tech enterprises in Shenzhen, with perfect import and export qualifications, and more than 10 years of experience in the production and operation of automation equipment.

Vility’s main products are CCD automation alignment machines which included in: CCD guide hole punching machine, CCD screen printing machine, CCD die cutting machine, CCD Fitting machine, Automation CCD testing machine for screen printing, Hardware, plastics and other industries. Those machines suit for both flat material and roll to roll material.And all products have obtained the domestic and international quality product certification,such as CE,ISO,CCC.

If you have any other requirements for product certification, please let us know.We will cooperate with you in accordance with your requirements to ensure that the products can go through the customs smoothly in the later testing and certification.

Q:Are you a factory or a distributor in China?

A:We are a professional factory for 10-years

Q: What kind of ink does your screen printing machine use?

A:All kinds of ink can print, like the solvent ink, water-based ink and plastical

Q: What’s your full automatic screen printing machine speed?

A:10-20 meter/ minute & 600-1200 meter/ hour

Q: How many kinds of material could be printed on?

A:Film & paper is OK, such as PET, PVC, PE, BOPP, PP

Q:What’s the material thickness & breadth range?

A:the thickness range: 0.02 -0.5 mm

the breadth range: 310-1600mm

Q. What other kinds of service can you offer?

A:We can offer screen film, screen ink supplier and various ancillary equipment and accessories

After-sales service is maintenance, not repair

High requirement and High demand label, you can give to Vility fully automatic screen printer

Q: What are the Certifications of your machines?

A:We have CE Certificate & ISO Certificate

Your Satisfaction is Our Honor!

PACKAGE:

The Automatic CCD alignment punching machine will be packed in strict safety before transportation.As shown in the picture below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen printing machine

Screen printing machine