Roll to Roll CCD Dislocated Dual Punching Machine Description

Automatic positioning, dual punching at one time, automaticalll correct pulling error to achieve manfree supervision for the whole roll material(cutter and die cutter can be equipped at the end of the punching machine to achieve one person handle one line)

Applicable to all kinds of trademarks, self-adhesive labels, cell phone keys / cell phone panels, conductive film, membrane switches / control surface paste, film, IMD / IML, FPC flexible circuit board, PET / PVC / PC / PP and other flexible materials positioning hole punching and slicing.

R2R CCD Alignment target hole punching machine

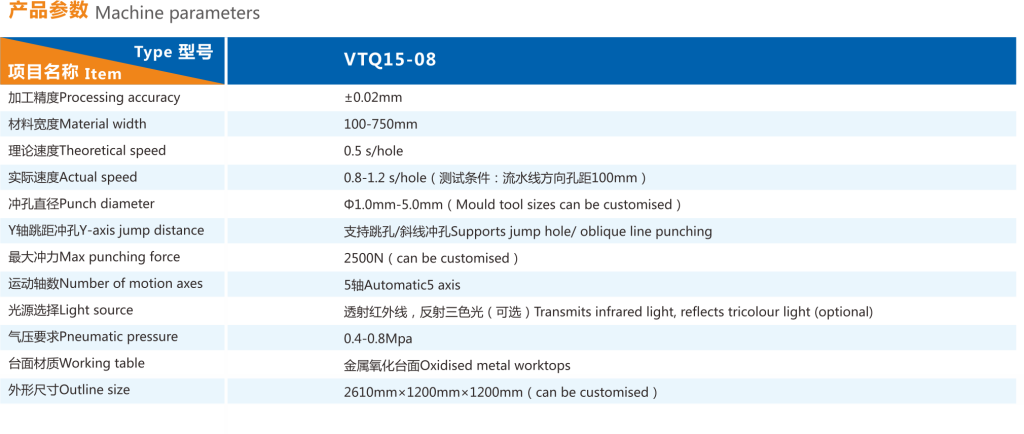

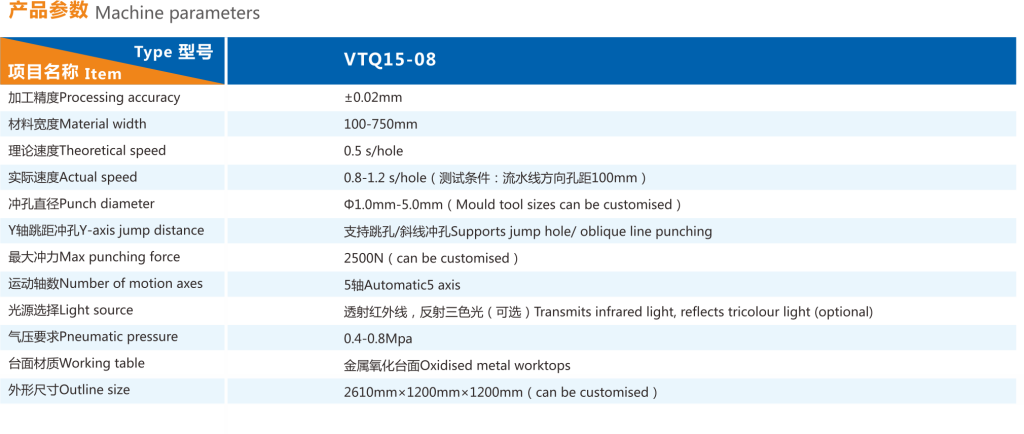

Staggered shift roll to roll CCD hole punching machine technical parameter:

Staggered shift roll to roll CCD hole punching machine

Roll to Roll CCD Dislocated Dual Puncher Application

Applied to Mobile phone keypad, mobile phone panel, conductive film, membrane switch, film, IMD/IML,FPC and other flexible roll to roll material

Staggered Shift Roll to Roll CCD Hole Punching Machine Punched Sample

Vility Automatic Industrial Machine Advantages:

1. All equipment is CE certified. And can be customized to meet customer requirements of other certification.

2. Our equipment is highly automated, and one person can man multiple production lines.

3. Accept OEM/ODM, screen printing industry whole line customization.

4. Printing, punching, die cutting precision 0.02mm.CCD camera visual alignment system, fast and accurate positioning and fine tuning, to ensure accuracy requirements.

R2R CCD Alignment target hole punching machine

Double Needles Staggered shift roll to roll CCD hole punching machine features:

1.Automatic light-sensitive material release: As long as the processed material is outside the infrared sensing range, the material release machine will automatically release the material and provide the material length required for the next feeding step.

- Automatic roller guide frame: the product is fixed by and around the guide block, which can ensure the product always keep the same direction.

- Dust removal and anti-static function: Dust removal and anti-static rollers are installed on the worktable surface, which can remove dust and static electricity from the product surface.Can design a auti-dust cover to protect any damage when machine working.

- Fast directional positioning: The worktable surface is equipped with directional positioning function to ensure that the products do not deviate from the material in the process of long-distance pulling.

- CCD image precise positioning: CCD industrial camera precise positioning, to ensure that the product is precisely positioned, and there will never be partial hole leakage phenomenon.

- Punching die: The punching die adopts imported high-speed steel and fine grinding processing and vacuum heat treatment to ensure the precision and service life of the die.

- Human-machine interface display: The punching machine adopts human-machine interface display, which can synchronously watch the actual punching.

8.N C servo feeder: NC servo feeder adopts imported Japanese Yaskawa servo feeder, the control panel can set 8 kinds of step, each feeding accuracy to ensure 0.03MM.

- CCD automatic positioning: the controller can be based on the last punching unit, through the CCD photo analysis, automatic feedback to control the pulling material fine-tuning pulling material step, to ensure the same

step, quick response time.

- Automatic cutting function(can be choose): After the product positioning hole processing OK, the cutting knife can be automatically cut by PLC signal.

- Discharge speed: It can be adjusted at will, and the starting frequency will rise slowly from 0 to running to avoid starting too fast and causing material surface abrasion.

- Punching speed: This equipment uses our self-developed VT series software, high-speed stable motor, high computing industrial computer

- Punching process can be set according to the whole sheet of material required punching Y direction step, longitudinal wide range of punching, to ensure that the material hole position can be all-round punching.

Shenzhen VILITY Automatic Machinery Co.,Ltd established in 2010 year, located in Shenzhen city, China. Our company’s development approach is : People-oriented, Technological innovation , service-oriented. VILITY is a combine-word, comes from Victory& Ability and Victory &Quality which means we always pursue high quality and good service to meet customers requirements and high competitive market. We believe: Service first, customers supreme. VILITY is a Professional manufacturer, providing ONE-STOP SOLUTION for intelligent printing industry. Recent years, We have pay most of the techniques and technologies to implement Industry 4.0 Robotic. VILITY has been successfully Provide unmanned production lines for many customers. Therefore, it is honored to get a high degree of social affirmation. Our main products are CCD automation alignment machines which included in: CCD guide hole punching machine, CCD screen printing machine, CCD die cutting machine, CCD Fitting machine, Automation CCD testing machine for screen printing, Hardware, plastics and other industries. Those machines suit for both flat material and roll to roll material. With substantial ongoing investment in research and development, VILITY is ideally positioned to continue doing high precision CCD robotic machines for both the commercial and domestic markets. We are looking forward to establishing well long –term business relationship with you and your esteemed companies.

Q:Are you a factory or a distributor in China?

A:We are a professional factory for 10-years

Q: What kind of ink does your screen printing machine use?

A:All kinds of ink can print, like the solvent ink, water-based ink and plastical

Q: What’s your full automatic screen printing machine speed?

A:10-20 meter/ minute & 600-1200 meter/ hour

Q: How many kinds of material could be printed on?

A:Film & paper is OK, such as PET, PVC, PE, BOPP, PP

Q:What’s the material thickness & breadth range?

A:the thickness range: 0.02 -0.5 mm

Q:Is it possible for you to assign engineers to our company?

A:yes. Our engineers can go to your company for on-site service. However, you need to pay the corresponding fee.

Q:Do you provide installation and training services?

A:Yes, we will provide you with professional installation and training manuals and video tutorials. Live video conversations will also be provided to guide you through the operation.

Q:What is your company’s production capacity?

A:30 Sets/ Month.

the breadth range: 310-1600mm

Q. What other kinds of service can you offer?

A:We can offer screen film, screen ink supplier and various ancillary equipment and accessories

After-sales service is maintenance, not repair

High requirement and High demand label, you can give to Vility fully automatic screen printer

Q:What’s the automatic roll to roll screen printing machine price?

A:Tell the truth, the price is not cheap, the price range is 39,000–190,000$.

As you know, only a reasonable profit can guarantee high quality

Q: What are the Certifications of your machines?

A:We have CE Certificate & ISO Certificate

Your Satisfaction is Our Honor!

PACKAGE:

Vility Industry Machine will be packed in strict safety before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the machinery, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen printing machine

Screen printing machine