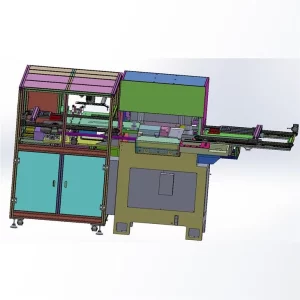

Large Roll to Roll CCD Alignment Hydraulic Press Description:

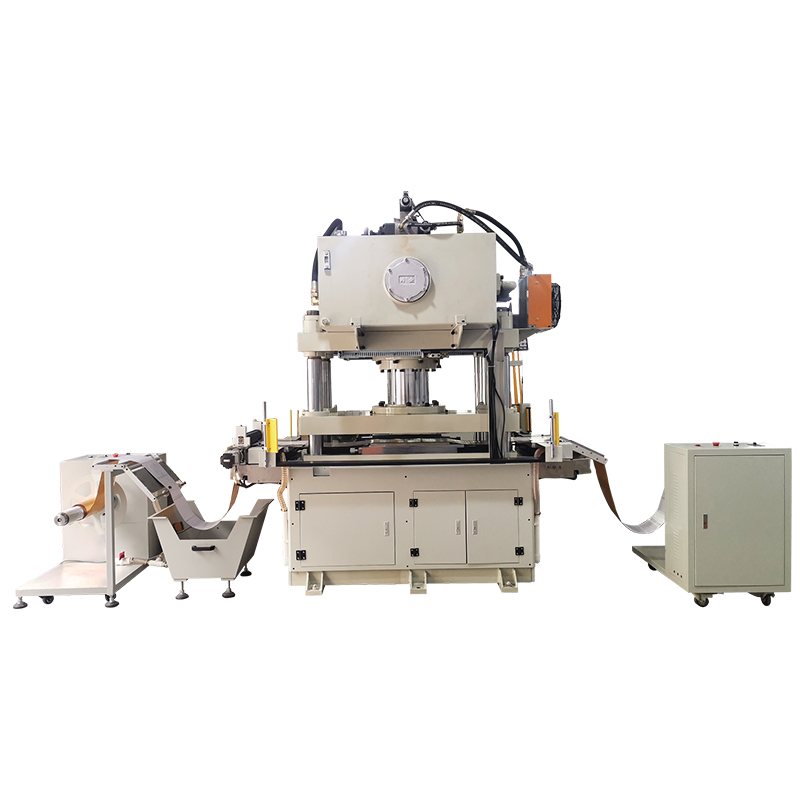

Vility Heavy Duty Automatic Punching and Die Cutting Machine is a hydraulic press specifically designed for LED strip circuit boards, with both die-cutting and slitting functions. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, etc. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel.

LED FPC Automatic Punching and Die Cutting Machine

Heavy Duty High Power Automatic Punching and Die Cutting Machine Specifications & Application:

Applied for power circuit panels, S-type FPC light strips, backlight panel, etc

Electronic products Roll to Roll CCD regulation stamping and die cutting machine,Advanced & durable hydraulic circuit and steady electronic control system circuits adopted in the hydraulic system enable to achieve high operating performance.

Automatic Punching and Die Cutting Machine Features

1) Adjust the feeding position of the manipulator and the CCD visual position of the positioning platform. Feeding and feeding position of feeding manipulator.

Automatic Punching Press Equipment Composition:

After the positioning of THE CCD initial positioning platform is completed, the feeding mechanical arm will send the material to the printing platform for CCD positioning again, and printing will be carried out after the completion

CCD automatic positioning punching, can automatically adjust the CCD field of view according to the size of the material.CCD automatically calculates the spatial position of the material and the die according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation automatic punching.

Alignment XYθ platform: Alignment XYθ platform is the core part of the machine, used for CCD visual alignment, this alignment platform is composed of XYθ4 axes, with alignment eccentricity function, alignment accuracy can be controlled within 0.02mm.

Automatic Die Cutting Machine Operating Procedure:

Feeder feeding – pulling system (pull material from point A to point B) – platform suction – CCD photography – platform alignment – punching – pulling system (pull material from point B to point C) – repeated production

LED FPC Automatic Punching and Die Cutting Machine

Vility Advantages:

1. All equipment is CE certified. And can be customized to meet customer requirements of other certification.

2. Our equipment is highly automated, and one person can man multiple production lines.

3. Accept OEM/ODM, screen printing industry whole line customization.

4. Printing, punching, die cutting precision 0.02mm.CCD camera visual alignment system, fast and accurate positioning and fine tuning, to ensure accuracy requirements.

Shenzhen VILITY Automatic Machinery Co.,Ltd established in 2010 year, located in Shenzhen city, China. Our company’s development approach is : People-oriented, Technological innovation , service-oriented. VILITY is a combine-word, comes from Victory& Ability and Victory &Quality which means we always pursue high quality and good service to meet customers requirements and high competitive market. We believe: Service first, customers supreme. VILITY is a Professional manufacturer, providing ONE-STOP SOLUTION for intelligent printing industry. Recent years, We have pay most of the techniques and technologies to implement Industry 4.0 Robotic. VILITY has been successfully Provide unmanned production lines for many customers. Therefore, it is honored to get a high degree of social affirmation. Our main products are CCD automation alignment machines which included in: CCD guide hole punching machine, CCD screen printing machine, CCD die cutting machine, CCD Fitting machine, Automation CCD testing machine for screen printing, Hardware, plastics and other industries. Those machines suit for both flat material and roll to roll material. With substantial ongoing investment in research and development, VILITY is ideally positioned to continue doing high precision CCD robotic machines for both the commercial and domestic markets. We are looking forward to establishing well long –term business relationship with you and your esteemed companies.

Q.Is it possible for you to assign engineers to our company?

yes. Our engineers can go to your company for on-site service. However, you need to pay the corresponding fee.

Q.Do you provide installation and training services?

Yes, we will provide you with professional installation and training manuals and video tutorials. Live video conversations will also be provided to guide you through the operation.

Q.What is your company’s production capacity?

30 Sets/ Month.

Vility Industry Machine will be packed in strict safety before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the machinery, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen printing machine

Screen printing machine