Vility Automatic Roll to Roll CCD Registration Screen Printing Machine Overview

Fully Automatic Roll-to-Roll Screen Printing Line, Fully Automatic RtR Screen Printing Equipment, Fully Automatic Reel-to-Reel Screen Press,

CCD registering screen printers, printing machines for wide application

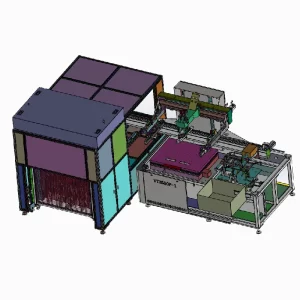

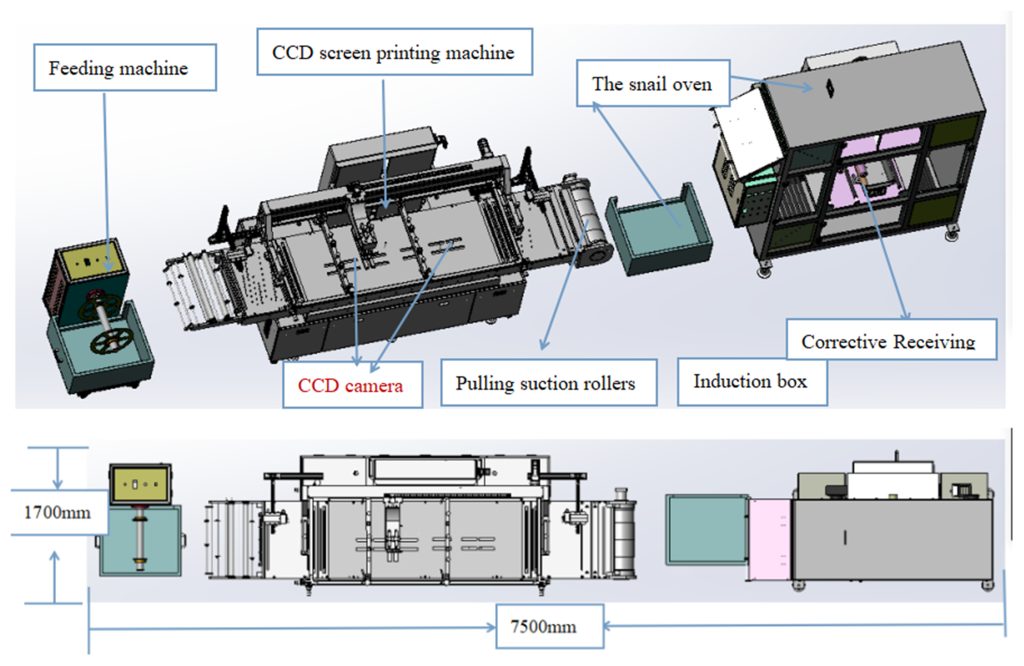

Fully Automatic Reel-to-Reel Screen Printing System Structure

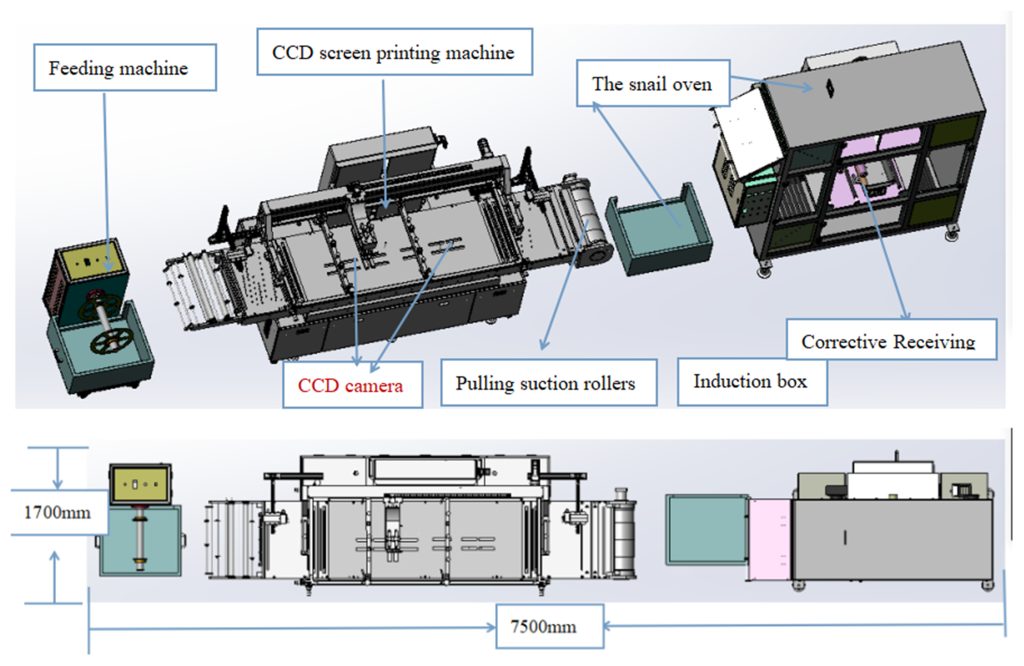

Roll to roll CCD alignment screen printing machine consists of three main parts: automatic feeding machine, CCD precision printing machine and automatic oven.

The whole production line can be controlled by one person, no pause in the printing process, high precision.The alignment error shall not exceed 0.02mm.

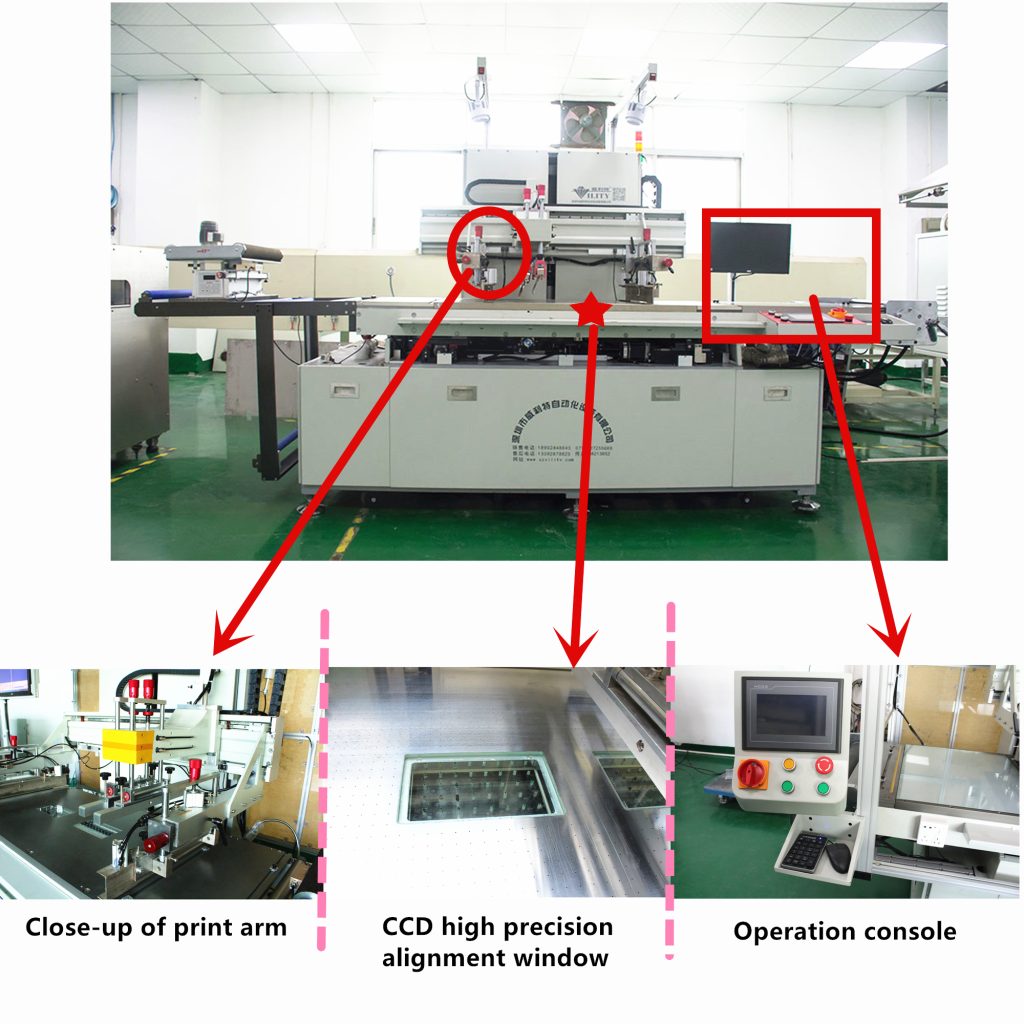

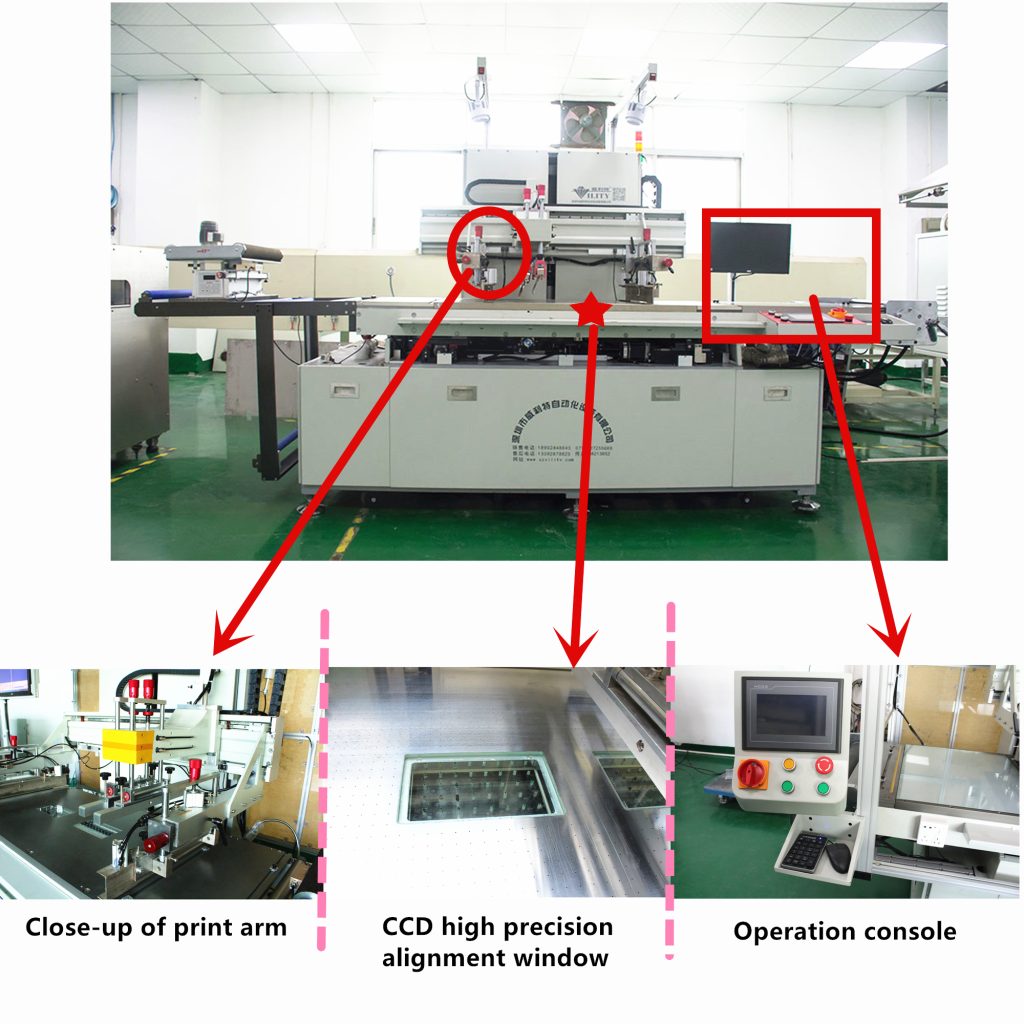

Roll to roll precision screen printing Machine Structure

Automatic CCD Positioning Screen Printing Machine For Roll To Roll Application :

The Fully Automatic Reel-to-Reel Screen Press is widely used in FPC,PET, PVC, varies of label,transfer paper (film), floor heating film, geothermal film, electro thermal film, color paper, film, name plate, flexible circuit board, mobile phone keys, Membrane switch, trademark printing, scratch CARDS, self-adhesive stickers, paper, ribbon, aluminum foil and copper foil this roll material silk screen printing.

High precision CCD vision alignment with 0.02mm error. Suitable for all flexible roll material printing.

Fully Automatic Roll-to-Roll Screen Printing Line Working Procedure:

Raw material →Automatic feeding machine →Automatic printing→Automatic UV or oven →Automatic receiving →End product.

Roll to Roll Automatic Screen Printing Machine Manufacturer Factory Shop

Fully Automatic High Precision RtR Screen Printing Equipment Features

(1). CCD automatic alignment system, if the similarity is not within the setting range, any abnormal, it will stop and automatically start adjust the alignment successful and continue to work.

(2). Using numerical control motor, printing speed, return to the ink speed can be set in a random block.

(3). Using numerical control motor, printing distance, return to the ink distance can be set in a random data.

(4). Automatic computing printing, and calculate the qty, and printing can be set automatically stop.

(5). photoelectric control feeding and discharging to avoid the surface damage of substrates, can improve the printing quality.

Roll to roll precision screen printing machine structure

Automatic Roll Material Loading Machine of Screen Printing Mahcines

Automatic Roll Material Feeder:

(1). Photoelectric control feeding, avoid the surface damage of the material.

(2). Feeding speed, time, can adjust at will.

(3). The feeding starting speed, can adjust at will, start frequency starting from 0 up to run slowly, avoid the start too fast,

cause the material surface scratches.

(4). Equipped with an automatic protective device.

Hot Air Drying Oven for Screen Printing Machine

Hot Air Drying Oven :

(1).Circulating hot air drying, temperature adjustable, automatic winding.

(2).The oven cover an small area, 32-60 meters length,

which can realize low temperature drying, ensure

printed material no shrinkage deformation,

multicolor printing.

With Vility Roll to Roll Automatic Screen Printing Machine

You can do automatic silk screen printing for below industry:

1/Mobile phone: case, shell, screen glass, circuit board , shading of screen and so on.

2/ Auto: Glass panel, Dashboard, automatic films, some auto decoration, many many application on auto industry.

3/ Printed Circuit: all kinds of circuit board and circuit film as well as membranes.

4/ IMD/IML, plastics industries….

Customization:

1/ CCD visual Alignment System, It’s the most advanced alignment technology used in screen printing. And the error can be kept in degree of microns.

2/ IR alignment and mark tracing system. Traditional working mode, widely accept by printing industries. Keep error in degree of millimeter.

3/Multi-colors Production Line. Depends on the types of ink and material, Printing unit can be linked up, and made multi-colors. Solution details need further discussion.

Precision Screen Printing Machine With Hot Air Drying Ove

Vility Roll Screen Printing Machine Features :

1. IR sensor for feeding and transport as well as rewinding. No jiggle when working situation.

2. Equipped with Panasonic servo motor, Efficient and stable, precise positioning.

3. Smart Operating system, language switch available. Smart, concise, and convenient.

4. Compact Design and durable metal plate, photoelectric switch, emergency stop button, Intelligent protection.

5. CCD automatic positioning and printing, automatically position adjusted according to the camera. Working table is rotary.

6. All working unit got dedusting function.

7. Labor saving, Automatic production line.

Q:Are you a factory or a distributor in China?

A:We are a professional factory for 10-years

Q: What kind of ink does your screen printing machine use?

A:All kinds of ink can print, like the solvent ink, water-based ink and plastical

Q: What’s your full automatic screen printing machine speed?

A:10-20 meter/ minute & 600-1200 meter/ hour

Q: How many kinds of material could be printed on?

A:Film & paper is OK, such as PET, PVC, PE, BOPP, PP

Q:What’s the material thickness & breadth range?

A:the thickness range: 0.02 -0.5 mm

the breadth range: 310-1600mm

Q. What other kinds of service can you offer?

A:We can offer screen film, screen ink supplier and various ancillary equipment and accessories

After-sales service is maintenance, not repair

High requirement and High demand label, you can give to Vility fully automatic screen printer

Q:What’s the automatic roll to roll screen printing machine price?

A:Tell the truth, the price is not cheap, the price range is 39,000–190,000$.

As you know, only a reasonable profit can guarantee high quality

Q: What are the Certifications of your machines?

A:We have CE Certificate & ISO Certificate

Your Satisfaction is Our Honor!

PACKAGE:

The Automatic Roll to Roll CCD alignment screen printing machine will be packed in strict safety before transportation.As shown in the figure above.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Screen Printing Machine Packing

Screen Printing Machine Shipping Way

Screen printing machine

Screen printing machine