Automatic Sheet to Sheet High Precision Screen Printing Machine (with CCD Visual Positioning System) Introduction:

Sheet to Sheet High Precision Screen Printing Press/Sheet to Sheet High Precision Screen Printer/Sheet to Sheet High Precision Screen Printing Equippment

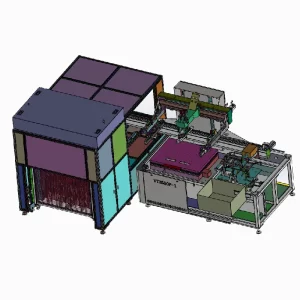

Vility’s CCD Alignment Screen Printing Machine for Sheet Material is the core machine of the sheet printing line.The whole process includes: automatic separate material – auto dust removal (including Initial positioning of clamping edge) – automatic loading – CCD alignment screen printing – automatic unloading – baking/drying – auto collecting the finished product.

automatic high precision screen printing machine for plastic, metal, glass film and plate sheet

CCD Positioning Sheet to Sheet Screen Printing Machine Standard Operating Procedure:

Raw material →Automatic feeding machine →Automatic printing→Automatic UV or oven →Automatic receiving →End product.

CCD Positioning Sheet to Sheet Screen Printing Press Application:

Vility’s Automatic Sheet to sheet CCD Alignment Screen Printing machine is perfect for printing electronics substrate material , such as graphic overlays, automotive dashboard, appliances panel, nameplates, flexible circuits, touch screen, aerospace label, diffuser, keyboard circuits, solar cell film,etc.

High alignment accuracy, fast printing speed and the entire production line can be operated by just one person.

The CCD Alignment Screen Printing Presses for Sheet is Divided into loading section, unloading section, printing section along with a shuttle table that moves from right to left(optional for printing table to move from left to right). Designed for manual loading /unloading of substrate; once the camera captures the target image the stage auto offsets and subsequently transports to printing section for printing.

Screen frame up/down movement :driven by servo motor and hall screw with clearance tolerance controlled with 50um

Automatically separate material→auto removal→auto loading→CCD alignment screen printing→auto unloading →dry →auto collecting the finished product.

The CCD Alignment Screen Printing System for Sheet is widely used in FPC,PET, PVC, transfer paper (film), floor heating film, geothermal film, electro thermal film, color paper, film, name plate, flexible circuit board, mobile phone keys, 3 m glue, glue, film switch, trademark laser, scratch CARDS, self-adhesive stickers, paper, ribbon, aluminum foil and copper foil this sheet material silk screen printing.

Sheet Material Flatbed Screen Print Machine

Sheet to Sheet CCD Registration Screen Printing Machine Key Features and Performance:

(1). CCD automatic alignment system, if the similarity is not within the setting range, any abnormal, it will stop and automatically start adjust the alignment successful and continue to work.

(2). Using numerical control motor, printing speed, return to the ink speed can be set in a random block.

(3). Using numerical control motor, printing distance, return to the ink distance can be set in a random data.

(4). Automatic computing printing, and calculate the qty, and printing can be set automatically stop.

(5). Photoelectric control feeding and discharging to avoid the surface damage of substrates, can improve the printing quality.

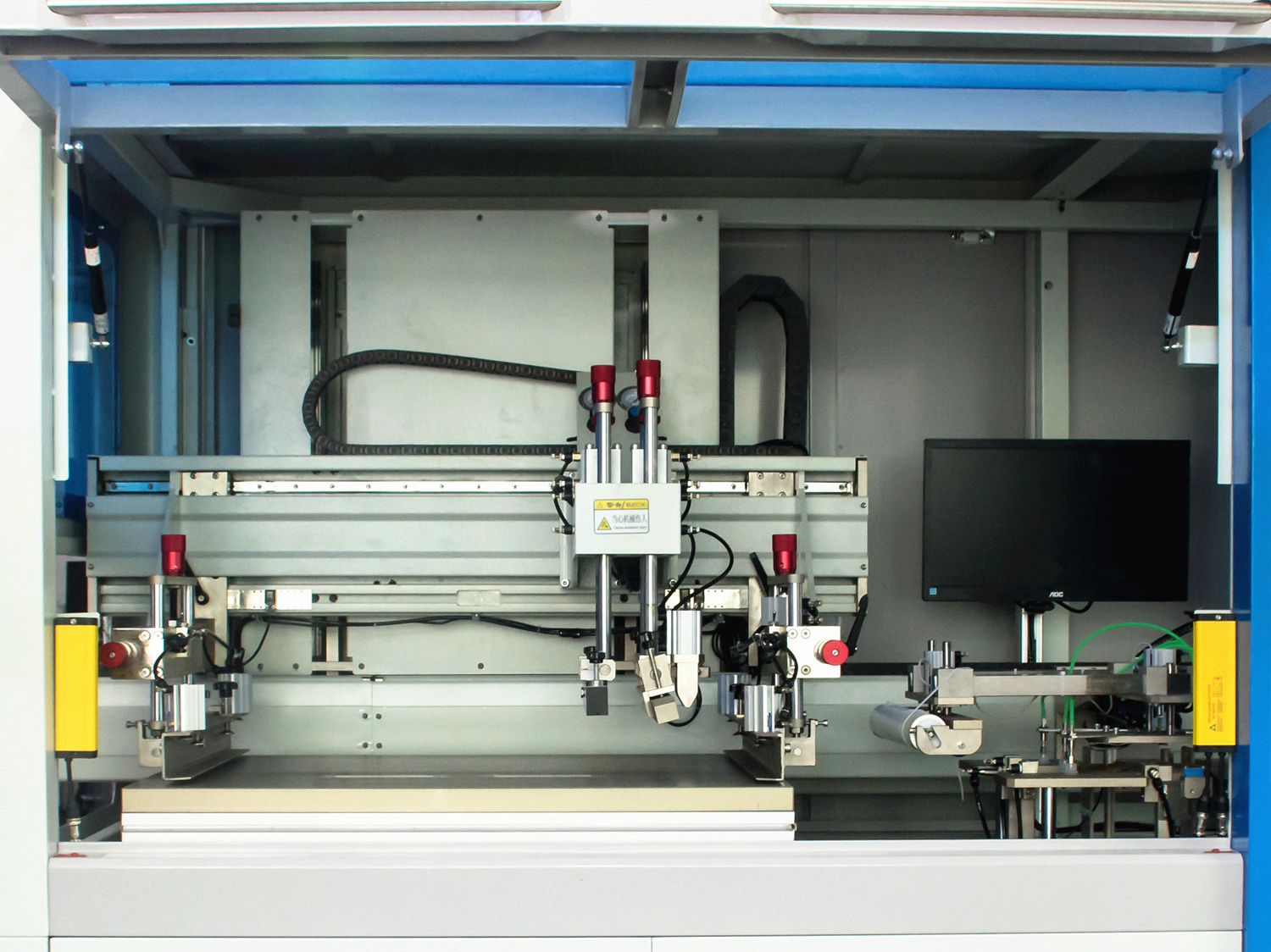

Sheet Material Auto Vacuum Loader for Screen Printing

Automatic vacuum loading device

By pumping air to create negative pressure,the glue head sucks up the sheet and

the mechanical arm repeatedly shakes to prevent the sheet from sticking.

The sheet is then placed precisely in the printing position.

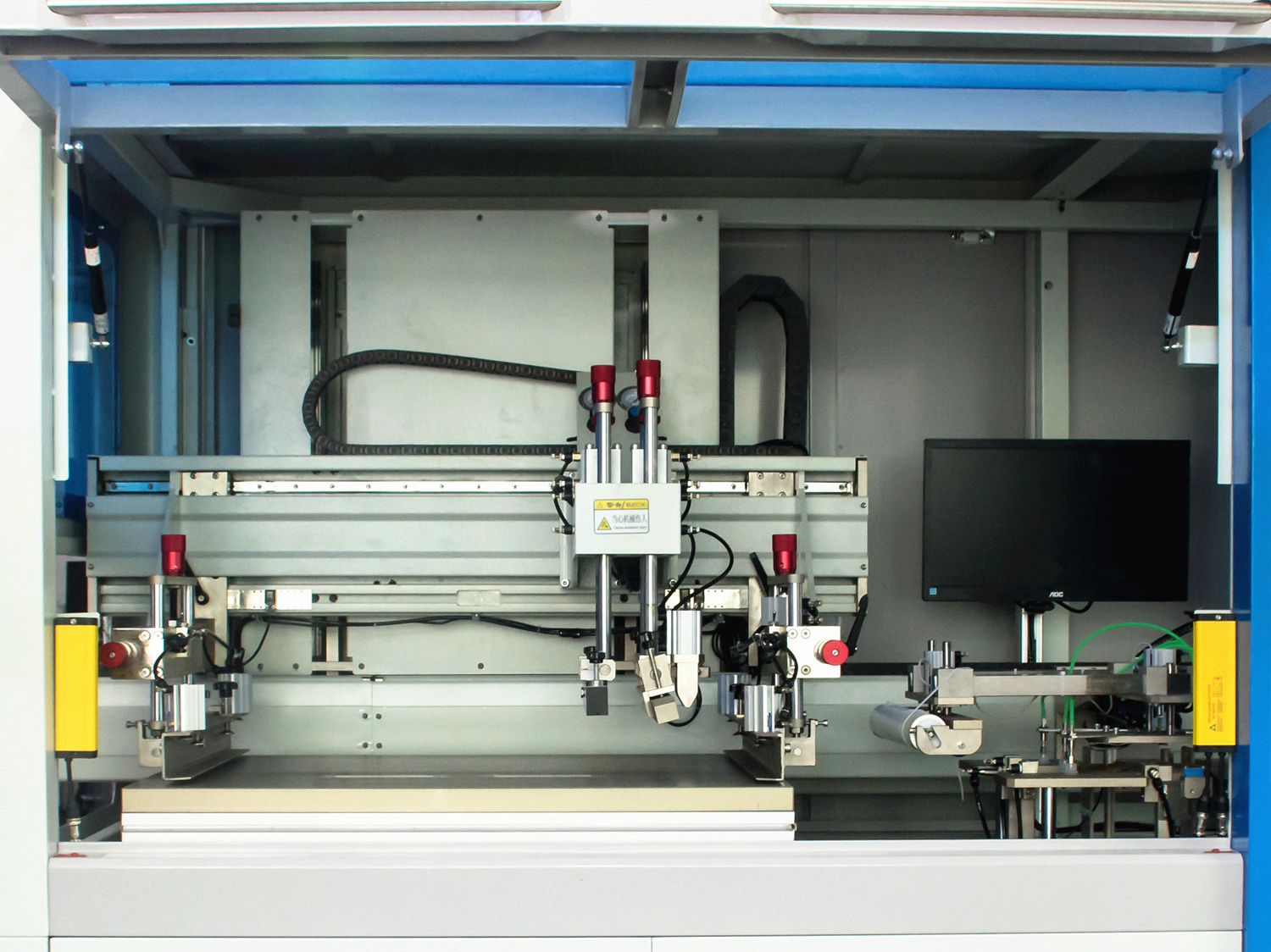

Printing Table and Printing Head of Screen Printing Press

Printing Table and Printing Head

Vaccum table with air suction during printing

process.

3 sensors for automatic register in X-Y

directions.

Printing head horizontal movement by servo

motor.

High precision rails and bearings for running

parts.

Squeegee dripless design

Industrial Automatic Drying Tunnels Furnace/Post Printing Equipment

Automatic dry tunnel furnace

After printing, the robot arm automatically

unloads the material onto the conveyor belt of

the dry tunnel furnace and is sent out by the

tail section at the end of drying. After drying

the sheet is ready for the next layer of

printing until the printing is complete.

screen printing machine Main machine feature

(1) Multicolor printing, automatic photocell eye counterpoint, computer control, automatic detection color code, if have any abnormal , it will stop automatic.

(2)Using numerical control motor, printing speed, return to the ink speed can be set in a random block.

(3) Using numericalcontrol motor, printing distance, return to the ink distance can be set in a random data.

(4)Automatic computing printing, andcalculate the qty, and printing can be set automatically stop.

(5)photoelectric control feeding and discharging to avoid thesurface damage of substrates, can improve the printing quality.

(6)Setting of printing speed and cycle run can be controlled via touch panel.

According to customers’ request, we accept customization, for example, adding anti-dust cover, exhuast cover, drying oven, tunnel furnace, UV curing machine, feeding direction, loading and unloading direction, etc.

The max feeding frame size is 400mmx500mm(can be customized), it can be adjustable after putting material on to fix them, right side, front and back sides are adjustable, it’s convenient for customer to make adjustment.

The advantage of this machine is printing platform automatic alignment with CCD camera positioning, it’s very suitable for printing multicolors which need high precision, the accuracy of camera positioning is ± 0.02mm, printing accuracy is ± 0.05mm, it can give customers a superior performance, and greatly improved production yield.

The printing scraper and blade adopt imported high level quality stainless steel, expanding printing usinglife, it has a pressure stabilizer ensuring constant pressure at all times.There’s a function that the height and oblique can be adjustable to improve printing quality.

All raw material we adopt high quality stainless steel, beautiful and longlife using.

User-friendly PC based control combined with touch screen monitor for maximum operational convenience.

The default language is Chinese-English, customer can convert to use, we also accept other language customization.

After-Sales Service

* Lifelong

* Spare parts

* Video technical and online support

* Field maintenance and repair service

* Engineers are available to service machinery overseas.

Q: Are you a factory or a trading company?

A: We are factory manufacturing packaging machines and we provide perfect OEM and after-sale service.

Q: Can you send me the video to show how the machine works?

A: Certainly, we have made video of every machine and uploaded them to Youtube.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, Western Union paying methods. For those orders less than 500USD, we accept PayPal to pay.Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

The screen printing equipment will be packed in woodply case( sea shipping export standard )before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the printing equipment, we generally use sea or road transport for transportation. You can choose to transport by sea route or by China-Europe Railway Express. As for the terms of trade, we usually adopt EXW,FOB or CIF.

The specific way can be confirmed in the process of communication and confirmation of the order..

Screen printing machine

Screen printing machine