Main mechanism of screen printing machine

Main mechanism of screen printing machine

Transmission device: motor, electromagnetic clutch, reducer, speed regulating mechanism.

Printing plate device: The screen printing plate must be fixed on the printing plate device in the screen printing machine. During the printing process, it can lift or lift horizontally like a book. Mainly include: printing plate holder, printing plate lifting mechanism, plate adjustment mechanism, and screen lifting compensation mechanism.

Printing device: Ink scraping and ink return are the main actions to achieve screen printing. The ink scraping system and the ink return system are usually installed on the scraper carriage. During the reciprocating motion, the ink scraping plate and the ink return plate rise and fall alternately, respectivamente. Realize the ink scraping and ink returning actions.

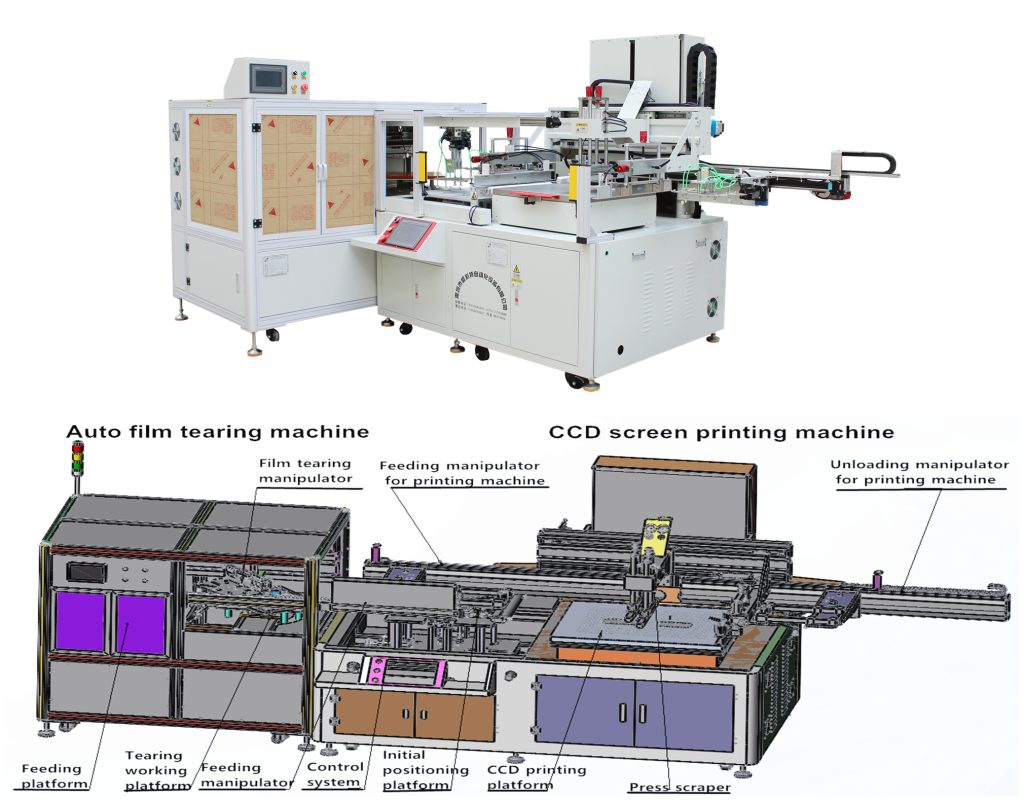

Automatic Sheet by Sheet Film-Tearing Screen Printing Machine Diagram

①To realize the printing reciprocating stroke, the following mechanisms are generally used: crank connecting rod mechanism, crank slider mechanism, chain sprocket mechanism, and cylindrical plug magnetic cylinder.

② The guide mechanism generally adopts the following form: roller groove rail, double guide shaft, guide shaft plus slider.

③The scraping and ink return plate transposition mechanism often adopts the following form:

The step groove lifting and lowering block plus a lever transposition mechanism, the cam lifting mechanism plus a lever transposition mechanism, the reverse action of two cylinders or a single cylinder plus a lever mechanism, the cam-swing bar mechanism pulls the steel wire plus a lever mechanism, and the change of the chain hanging point makes the two plates When swinging the angle step and using one scraper instead of two scrapers, an ink jumping action is required, and the ink jumping action is completed by a specific mechanism.

The supporting device is the printing platform: it is used to fix the printing material.

①It should have a print positioning device.

② Platform height and level adjustment device.

Alignment mechanism: The position of the platform moves during plate alignment, which is generally achieved by mechanical thread rotation, and should have reliable locking devices and displacement guides (dovetail grooves or guide keys, etc.).

Drying device: infrared electric heating tube hot air drying or ultraviolet light curing drying device.

Electrical control device: working cycle control, scraper position control, air pressure control.

Serigrafia

Serigrafia