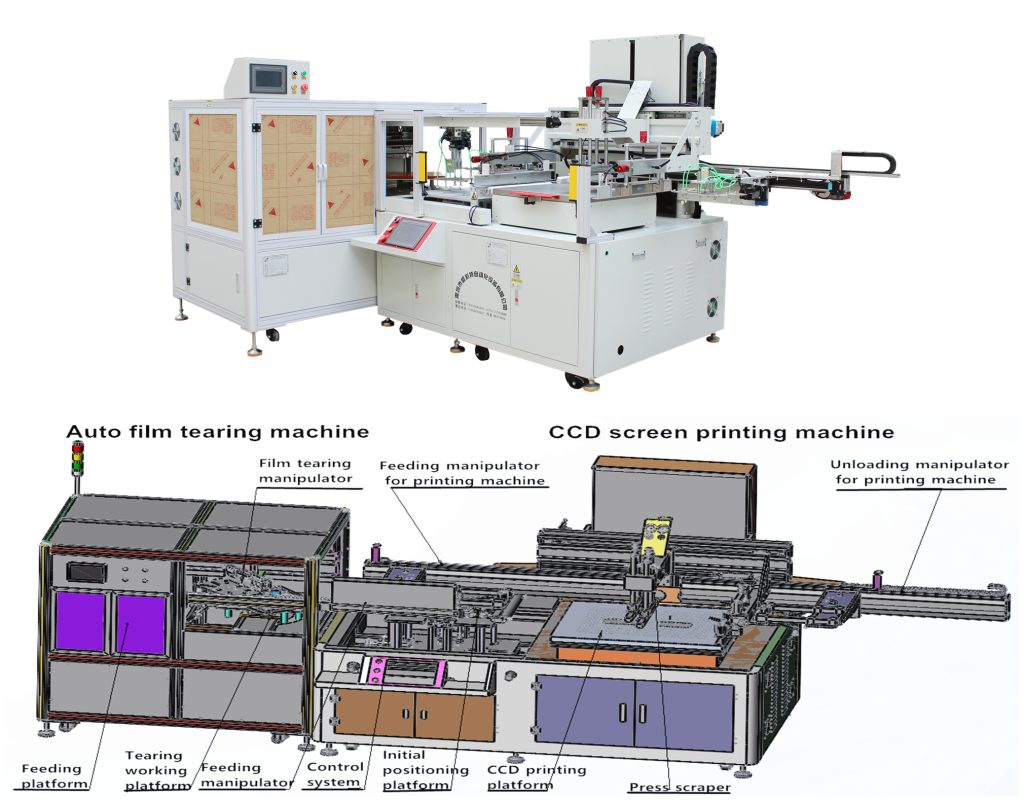

Automatic Sheet by Sheet High Precision Film-Tearing Screen Printing Machine Description

Automatic Sheet by Sheet Film-Tearing Screen Printing Equipment/Automatic Sheet by Sheet Film-Tearing Screen Printing Printer/Automatic Sheet by Sheet Film-Tearing Screen Press

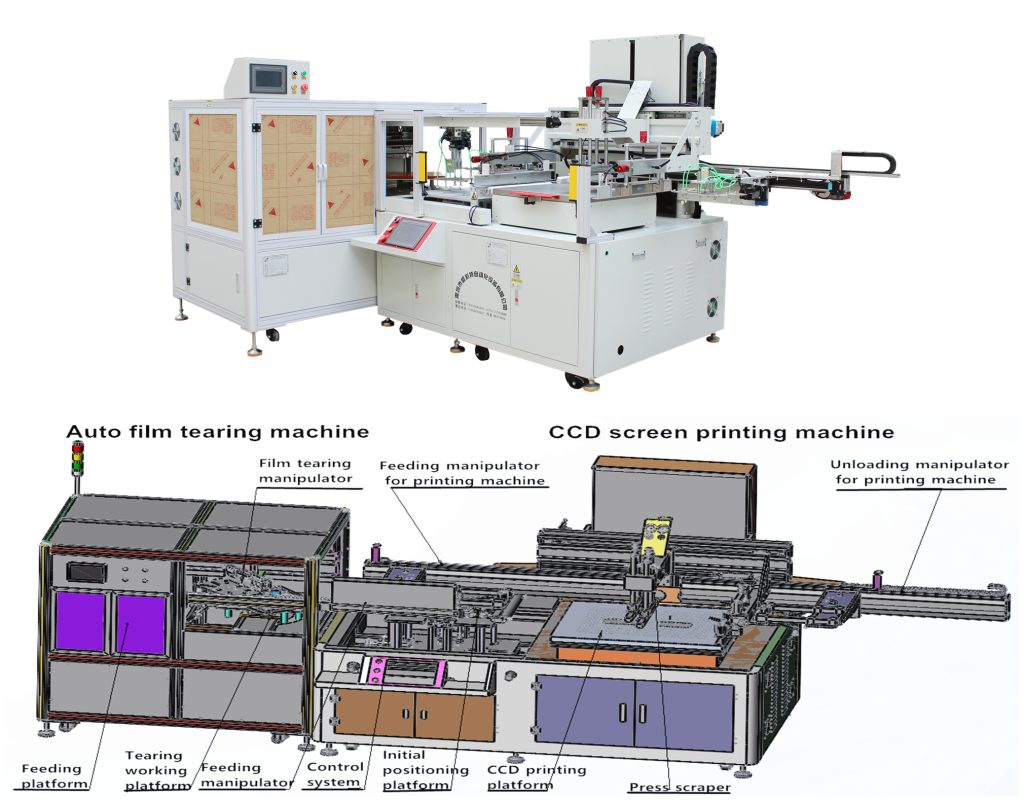

The Automatic alignment printing machine with film tearing machine is the addition of an automatic film tearer to the conventional CCD printing machine. It is used for precision materials where the protective film of the sheet needs to be removed before printing.

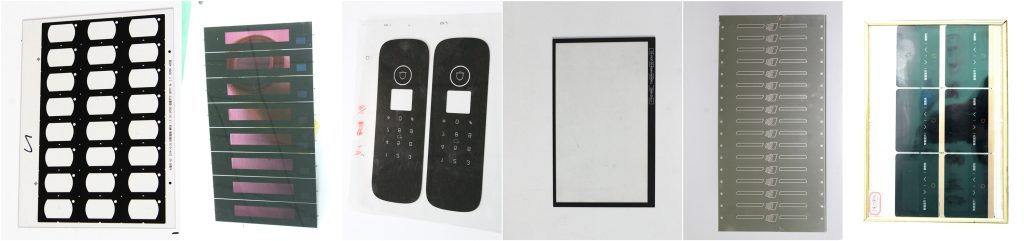

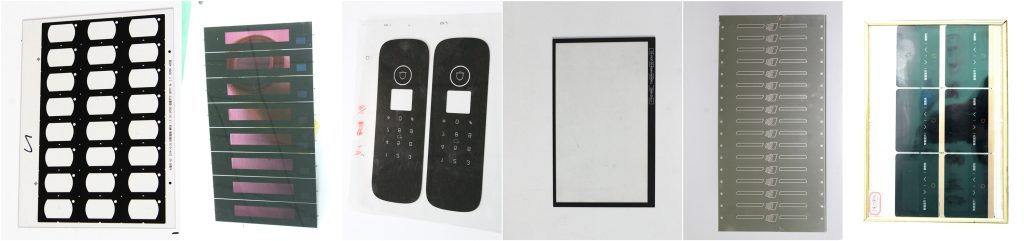

The Automatic alignment printing machine with film tearing is suitable for printing on sheet materials such as: interruptores de membrana, tampas de vidro, acrylic, ITO, Filmes condutores, composite back covers, etc.

Alta precisão de alinhamento, velocidade de impressão rápida e toda a linha de produção pode ser operada por apenas uma pessoa.

Automatic Sheet by Sheet Film-Tearing Screen Printing Machine

Automatic Film-tearing CCD Screen Printing Machine Application :

This machine is widely used in FPC,Animal de estimação, PVC, varies of label,papel de transferência (filme), filme plástico para aquecimento de piso, filme geotérmico, electro thermal film, papel colorido, filme, placa de identificação, flexible circuit board, chaves do telefone celular, Membrane switch, trademark printing, scratch CARDS, autocolantes autocolantes, papel, fita, aluminum foil and copper foil this roll material silk screen printing.

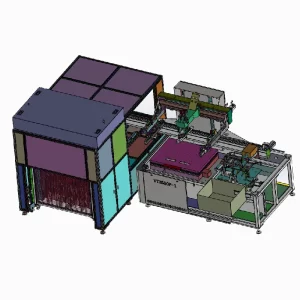

Automatic Sheet by Sheet Film-Tearing Screen Printing Printer Structure:

Automatic alignment printing machine with film tearing Divided into automatic tear film section , loading section, unloading section, printing section along with a shuttle table that moves from right to left(optional for printing table to move from left to right).

Designed for manual loading /unloading of substrate; once the camera captures the target image the stage auto offsets and subsequently transports to printing section for printing.

Screen frame up/down movement :driven by servo motor and hall screw with clearance tolerance controlled with 50um.

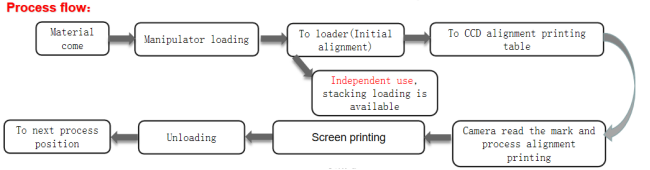

Automatic Sheet by Sheet Film-Tearing Screen Printing Machine Diagram

Automatic Film-Tearing High Precision Screen Printing Press Operating Process:

The whole process includes:

Feeding on the loading platform.

Tearing robot feeds and tears the film

Tearing robot feeds and tears the film.

Feeding robot feeds the material (

delivers the torn material to the initial positioning platform).

The material passes through the guides for initial positioning

The material passes through the guides for initial positioning.

Loading of the screen printing machine by the loading robot

Loading of the screen printing machine by the loading robot.

CCD screen printing machine alignment printing

CCD screen printing machine alignment printing.

Screen printer pick-up robot picks up the material

Screen printer pick-up robot picks up the material.

Automatic Sheet by Sheet Film-Tearing Screen Printing Equipment Features:

film tearing machine

film tearing machine

1. The auto film tearing machine adopts microcomputer control, servo motor drags the material, and automatically tears the edge to realize fully automatic production.

2. Arbitrary fixed length, step length photoelectric tracking, accurate and stable, automatic shutdown when label is lost, e

photoelectric control of feeding.

3. Automatic counting and counting alarm can be set.

feeding manipulator for positioning platform

Feeding manipulator for positioning platform

After the sheet protection film has been torn off, it is sent to the initial positioning platform via this negative pressure manipulator. The manipulator at this point serves the function of connecting the film- tearing to the CCD printing machine. It is also initially positioned under the control of the computer system to facilitate the subsequent pick-up and printing by the printing machine.

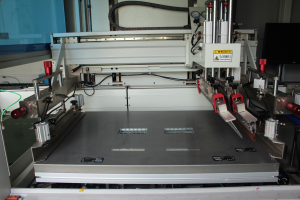

Automatic vacuum loading device for printer

Automatic vacuum loading device for printer

By pumping air to create negative pressure, the glue head sucks up the sheet and the mechanical arm repeatedly shakes to prevent the sheet from sticking. The sheet is then placed precisely in the printing position.

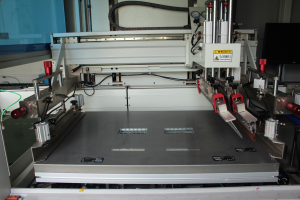

Printing Table and Printing Head

Printing Table and Printing Head

Mesa de vácuo com sucção de ar durante o processo de impressão. 3 sensores para registro automático em direções X-Y. Movimento horizontal da cabeça de impressão por servo motor. Trilhos e rolamentos de alta precisão para peças em movimento. Design sem gotejamento do rodo

Automatic dry tunnel furnace

Automatic dry tunnel furnace

Após a impressão, the robot arm automatically unloads the material onto the conveyor belt of the dry tunnel furnace and is sent out by the tail section at the end of drying. After drying the sheet is ready for the next layer of printing until the printing is complete.

The reason for choosing Vility

1. We are Factory and have above 10 years experiences for research and production machines.

2. We own experienced R&D teams.

3. We can supply fully after-sales service.

Q:Você é manufactory ou empresa comercial?

VILITY é uma manufatura famosa do tipo da cidade de Shenzhen, Província de Guangdong, China.

Q:Você pode fazer um projeto específico de acordo com nossos requisitos?

Sim, nós podemos fazer uma mudança especial de acordo com suas necessidades.

Q:Quais são as suas condições de pagamento?

50% depósito e 50% Saldo antes da entrega, T/T contra cópia do conhecimento de desembarque.

Q:Qual é a capacidade de produção da sua empresa?

30 Conjuntos/Mês.

Q:Quais certificações você possui?

Nós temos o CE,ISO90001 e outras certificações.

Q:Qual é o período de garantia do seu equipamento?

Nós garantimos a máquina inteira por um ano e proporcionamos o serviço de melhoramento de software de vida.

Q:Você fornece serviços de instalação e treinamento?

Sim, Forneceremos manuais profissionais de instalação e treinamento e tutoriais em vídeo. Conversas de vídeo ao vivo também serão fornecidas para guiá-lo durante a operação.

PACOTE:

The Automatic Roll to Roll CCD alignment screen printing machine will be packed in strict safety before transportation.As shown in the figure above.Try to ensure that no damage occurs in the course of transportation.

Devido ao grande tamanho e massa pesada do equipamento de impressão, Geralmente usamos transporte marítimo ou rodoviário para transporte. Você pode optar por transportar por rota marítima ou por China-Europe Railway Express. Quanto aos termos de troca, geralmente adotamos EXW,FOB ou CIF.

A forma específica pode ser confirmada no processo de comunicação e confirmação do pedido.

TEMPO DE ENTREGA:

3-20 dias após a confirmação da ordem,a data de entrega do detalhe deve ser decidida de acordo com

Temporada de produção e quantidade do pedido.

Embalagem da máquina de impressão da tela

Serigrafia

Serigrafia