Vility Automatic Roll to Roll CCD Registration Screen Printing Machine Overview

Fully Automatic Roll-to-Roll Screen Printing Line, Fully Automatic RtR Screen Printing Equipment, Fully Automatic Reel-to-Reel Screen Press,

CCD registering screen printers, printing machines for wide application

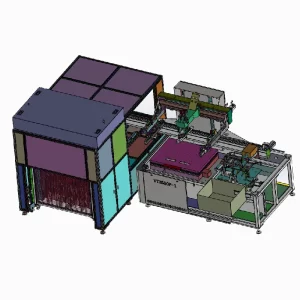

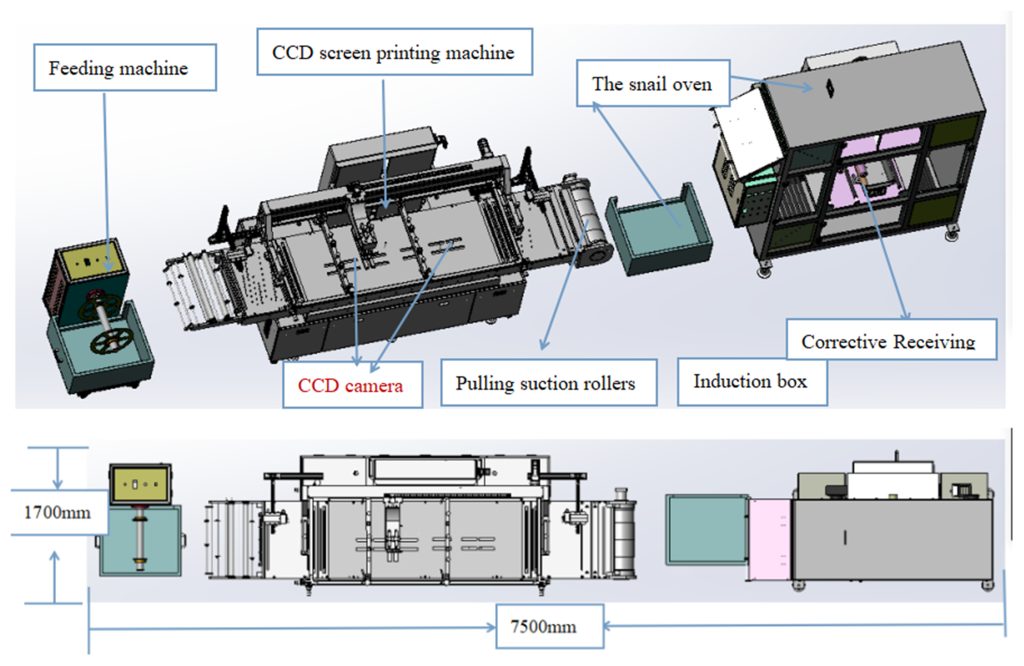

Fully Automatic Reel-to-Reel Screen Printing System Structure

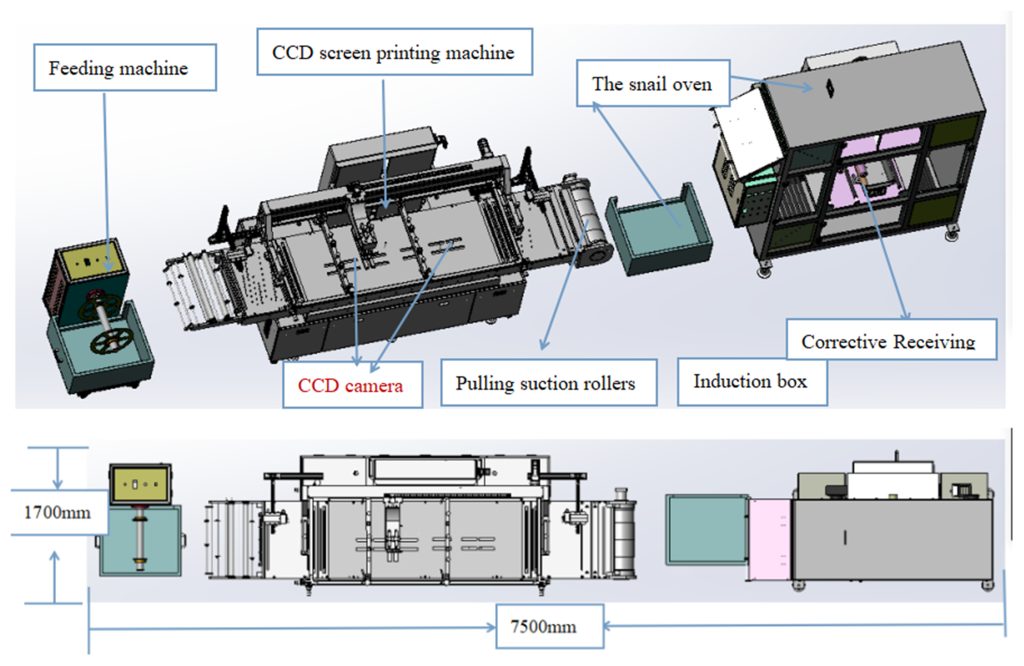

Roll to roll CCD alignment screen printing machine consists of three main parts: automatic feeding machine, CCD precision printing machine and automatic oven.

The whole production line can be controlled by one person, no pause in the printing process, high precision.The alignment error shall not exceed 0.02mm.

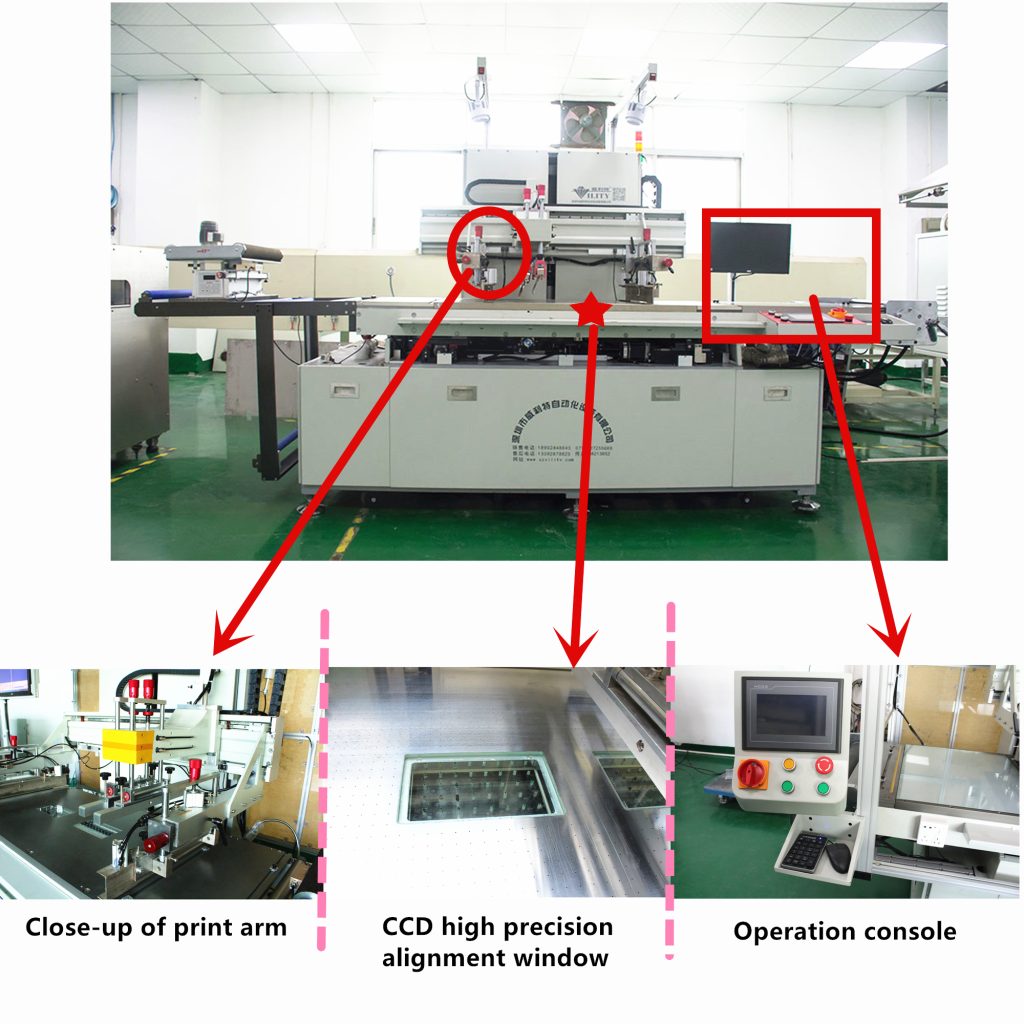

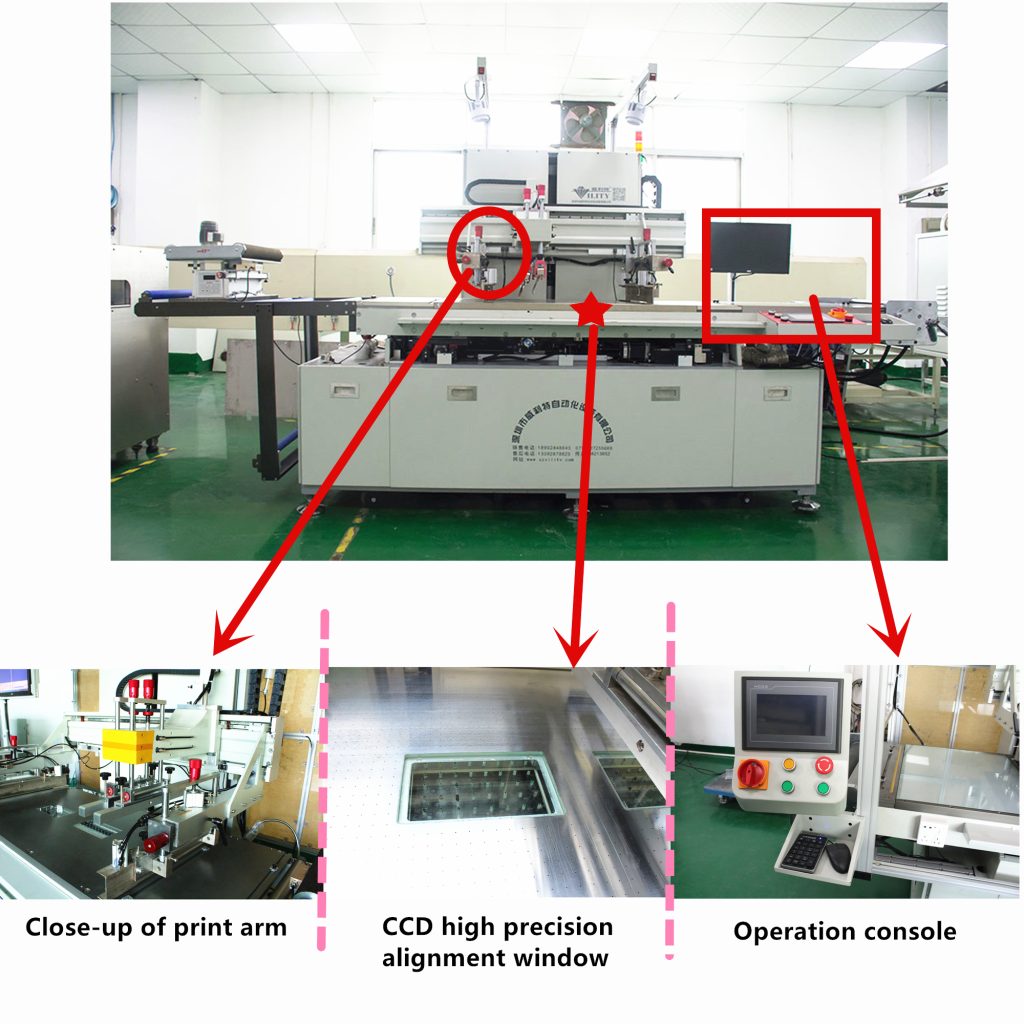

Roll to roll precision screen printing Machine Structure

Automatic CCD Positioning Screen Printing Machine For Roll To Roll Application :

The Fully Automatic Reel-to-Reel Screen Press is widely used in FPC,Animal de estimação, PVC, varies of label,papel de transferência (filme), filme plástico para aquecimento de piso, filme geotérmico, eletro filme térmico, papel colorido, filme, placa de identificação, flexible circuit board, chaves do telefone celular, Membrane switch, trademark printing, scratch CARDS, autocolantes autocolantes, papel, fita, aluminum foil and copper foil this roll material silk screen printing.

High precision CCD vision alignment with 0.02mm error. Suitable for all flexible roll material printing.

Fully Automatic Roll-to-Roll Screen Printing Line Working Procedure:

Matéria-prima → Máquina de alimentação automática → impressão automática→ UV automático ou forno → recebimento automático →produto final.

Roll to Roll Automatic Screen Printing Machine Manufacturer Factory Shop

Fully Automatic High Precision RtR Screen Printing Equipment Features

(1). CCD automatic alignment system, if the similarity is not within the setting range, any abnormal, it will stop and automatically start adjust the alignment successful and continue to work.

(2). Using numerical control motor, velocidade de impressão, return to the ink speed can be set in a random block.

(3). Using numerical control motor, printing distance, return to the ink distance can be set in a random data.

(4). Automatic computing printing, and calculate the qty, and printing can be set automatically stop.

(5). photoelectric control feeding and discharging to avoid the surface damage of substrates, can improve the printing quality.

Roll to roll precision screen printing machine structure

Automatic Roll Material Loading Machine of Screen Printing Mahcines

Automatic Roll Material Feeder:

(1). Photoelectric control feeding, avoid the surface damage of the material.

(2). Feeding speed, time, can adjust at will.

(3). The feeding starting speed, can adjust at will, start frequency starting from 0 up to run slowly, avoid the start too fast,

cause the material surface scratches.

(4). Equipped with an automatic protective device.

Hot Air Drying Oven for Screen Printing Machine

Hot Air Drying Oven :

(1).Circulating hot air drying, temperature adjustable, automatic winding.

(2).The oven cover an small area, 32-60 meters length,

which can realize low temperature drying, ensure

printed material no shrinkage deformation,

multicolor printing.

With Vility Roll to Roll Automatic Screen Printing Machine

You can do automatic silk screen printing for below industry:

1/Mobile phone: case, shell, screen glass, circuit board , shading of screen and so on.

2/ Auto: Glass panel, Dashboard, automatic films, some auto decoration, many many application on auto industry.

3/ Printed Circuit: all kinds of circuit board and circuit film as well as membranes.

4/ IMD/IML, plastics industries….

Customization:

1/ CCD visual Alignment System, It’s the most advanced alignment technology used in screen printing. And the error can be kept in degree of microns.

2/ IR alignment and mark tracing system. Traditional working mode, widely accept by printing industries. Keep error in degree of millimeter.

3/Multi-colors Production Line. Depends on the types of ink and material, Printing unit can be linked up, and made multi-colors. Solution details need further discussion.

Precision Screen Printing Machine With Hot Air Drying Ove

Vility Roll Screen Printing Machine Features :

1. IR sensor for feeding and transport as well as rewinding. No jiggle when working situation.

2. Equipped with Panasonic servo motor, Efficient and stable, precise positioning.

3. Smart Operating system, language switch available. Smart, concise, and convenient.

4. Compact Design and durable metal plate, interruptor fotoelétrico, botão de parada de emergência, Intelligent protection.

5. CCD automatic positioning and printing, automatically position adjusted according to the camera. Working table is rotary.

6. All working unit got dedusting function.

7. Labor saving, Automatic production line.

Q:Você é uma fábrica ou um distribuidor na China?

Um:Nós somos uma fábrica profissional por 10 anos

Q: Que tipo de tinta sua máquina de serigrafia usa?

Um:Todos os tipos da tinta podem imprimir, como a tinta solvente, tinta à base de água e plástico

Q: Qual é a velocidade da sua máquina de serigrafia totalmente automática?

Um:10-20 metro/ minuto & 600-1200 metro/ hora

Q: Quantos tipos de material podem ser impressos em?

Um:Filme & papel está OK, como PET, PVC, PE, BOPP, PP

Q:Qual é a espessura do material & amplitude?

Um:a faixa de espessura: 0.02 -0.5 milímetro

A amplitude: 310-1600milímetro

Q. Que outros tipos de serviço você pode oferecer?

Um:Nós podemos oferecer filme de tela, fornecedor de tinta de tela e vários equipamentos auxiliares e acessórios

O serviço pós-venda é manutenção, não reparar

Etiqueta de alta exigência e alta demanda, você pode dar à impressora de tela totalmente automática Vility

Q:Qual é o preço da máquina de serigrafia rolo a rolo automático?

Um:Diga a verdade, o preço não é barato, the price range is 39,000–190,000$.

Como você sabe, Somente um lucro razoável pode garantir alta qualidade

Q: Quais são as certificações de suas máquinas?

Um:Nós temos o certificado do CE & Certificado ISO

Sua satisfação é nossa honra!

PACOTE:

The Automatic Roll to Roll CCD alignment screen printing machine will be packed in strict safety before transportation.As shown in the figure above.Try to ensure that no damage occurs in the course of transportation.

Devido ao grande tamanho e massa pesada do equipamento de impressão, Geralmente usamos transporte marítimo ou rodoviário para transporte. Você pode optar por transportar por rota marítima ou por China-Europe Railway Express. Quanto aos termos de troca, geralmente adotamos EXW,FOB ou CIF.

A forma específica pode ser confirmada no processo de comunicação e confirmação do pedido.

TEMPO DE ENTREGA:

3-20 dias após a confirmação da ordem,a data de entrega do detalhe deve ser decidida de acordo com

Temporada de produção e quantidade do pedido.

Embalagem da máquina de impressão da tela

Forma de envio da máquina de serigrafia

Serigrafia

Serigrafia