Sheet to Sheet Automatic CCD Vision Die Cutting Machine Description

CCD positioning sheet to sheet die-cutting machine is a kind of high-precision and high-efficiency automatic die-cutting equipment. Among them, the equipment mainly contains: CCD moving platform, high precision XYθ alignment platform, pulling mechanism, guiding mechanism, releasing mechanism, punching and cutting mechanism. The die-cutting machine has the functions of automatic material pulling, automatic alignment, automatic slicing, etc. The finished die-cutting products and scrap are separated according to the specified track. Once the equipment is adjusted, the machine will be automatically completed without any operation by personnel. The picture below is the machine design and the actual picture of the die cutting machine.

Vility Sheet to Sheet Automatic CCD Vision Die Cutting Machine

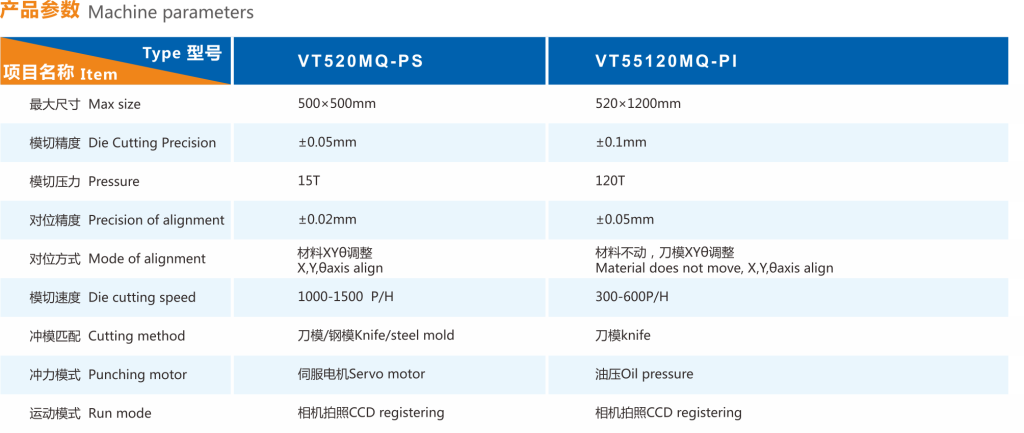

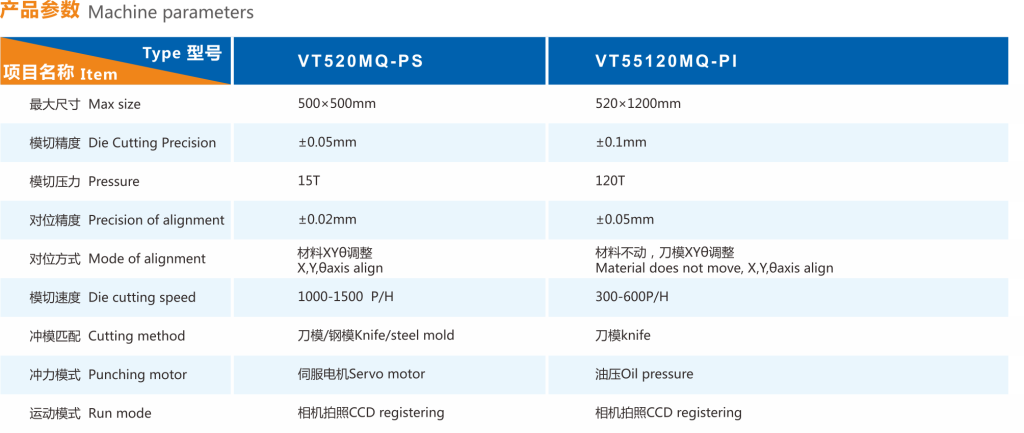

Sheet to Sheet Automatic CCD Vision Die Cutter Application & Specifications:

Membrane switch,ITO/PET/PVCPC.conductive film. iMD household appliance pane. automotive pane. mobile phone diaphragm. etc.- after printing or embodvinCCD positioning die cutting, it can be automatic high-precision die cutting without target hole.

Full servo drive type.

PLC computer touch-panel screen control system.

High speed die cutting (stroke time: 5sec).

Full die cutting and half die cutting in process.

Equipped with high precision mold high fine adjustment control, Four-columns can be micro-adjusted independently by computer setting parameter, to save time and to raise the production rate.

Optional equipped with front & back dual direction feeding or Full automatic feeding mechanism.

Non-hydraulic design, no pollution, low vibration and low noise, to save more than 30% of energy loss comparing with traditional hydraulic machine, best for using in dustless room.

This equipment mainly includes die-cutting unit, equipped with CCD moving platform on both sides of the die-cutting unit, high precision XYθ alignment platform, stable alignment, human-machine interface control + button switch, can set a variety of functional parameters, easy to operate; CCD automatic positioning punching, can automatically adjust the field of view of CCD according to the size of the material.

CCD automatically calculates the spatial position of material and mold according to the MARK point on the material, and instructs the motor motion control to adjust the platform XYθ rotation for automatic punching and cutting.

1. Alignment XYθ platform: Alignment XYθ platform is the core part of the machine, used for CCD vision alignment, this alignment platform is composed of XYθ4 axes, with alignment eccentricity function, alignment accuracy can be controlled within 0.02mm.

2. Feeding machine:Feeder is used for coil feeding, die-cutting machine each time cutting, pulling drum will pull a product jump distance, at the same time feeding machine and then feeding. Ensure the efficiency of punching.

Sheet to Sheet Automatic CCD Vision Die Cutter Work Flow

After the material is discharged, the CCD visual positioning detection sends the error value of PET and the positioning standard to the IPC, which specifies the motor XYθ movement until the MARK point of PET and the positioning standard are positioned according to the set accuracy, sends a signal to the die-cutting machine, which stamps. After the stamping is completed, the machine enters the next cycle of operation.

Q:Are you a factory or a distributor in China?

A:We are a professional factory for 10-years

Q: What kind of ink does your screen printing machine use?

A:All kinds of ink can print, like the solvent ink, water-based ink and plastical

Q: What’s your full automatic screen printing machine speed?

A:10-20 meter/ minute & 600-1200 meter/ hour

Q: How many kinds of material could be printed on?

A:Film & paper is OK, such as PET, PVC, PE, BOPP, PP

Q:What’s the material thickness & breadth range?

A:the thickness range: 0.02 -0.5 milimetru

Q:Is it possible for you to assign engineers to our company?

A:yes. Our engineers can go to your company for on-site service. However, you need to pay the corresponding fee.

Q:Oferiți servicii de instalare și instruire?

A:Da, Vă vom oferi manuale profesionale de instalare și instruire și tutoriale video. De asemenea, vor fi furnizate conversații video live pentru a vă ghida prin operațiune.

Q:Care este capacitatea de producție a companiei tale?

A:30 Seturi/ Lună.

Q. What other kinds of service can you offer?

A:We can offer screen film, screen ink supplier and various ancillary equipment and accessories

After-sales service is maintenance, not repair

High requirement and High demand label, you can give to Vility fully automatic screen printer

Q:What’s the automatic roll to roll screen printing machine price?

A:Tell the truth, the price is not cheap, the price range is 39,000–190,000$.

As you know, only a reasonable profit can guarantee high quality

Q: What are the Certifications of your machines?

A:We have CE Certificate & ISO Certificate

PACHET:

Vility Industry Machine will be packed in strict safety before transportation.As shown in the figure below.Try to ensure that no damage occurs in the course of transportation.

Due to the large size and heavy mass of the machinery, folosim în general transportul maritim sau rutier pentru transport. Puteți alege să transportați pe cale maritimă sau cu China-Europe Railway Express. În ceea ce privește termenii schimbului, de obicei adoptăm EXW,FOB sau CIF.

Modul specific poate fi confirmat în procesul de comunicare și confirmare a comenzii.

TIMP DE LIVRARE:

3-20 zile de la confirmarea comenzii,data de livrare detaliată trebuie decisă în funcție de

Sezonul de producție și cantitatea comenzii.

Mașină de serigrafie

Mașină de serigrafie