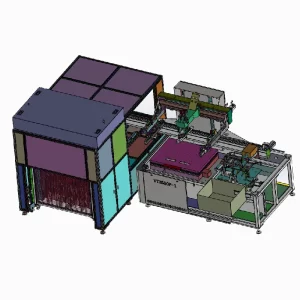

Рулонная машина для трафаретной печати с регистрацией CCD (Четыре поста) Description

Roll to roll screen printing machine Automatic and High Precision

1. CCD camera positioning system, Rotating printing table, Automatic positioning and printing.

2. High working precision , accuracy up to 0.02mm.

3. Automatic roller motor, anti-static and roller with dust cleaning

4. High efficiency, 1500 meters working speed per hour.

Full Automatic Roll to Roll CCD Visual Alignment Screen Printing Machine (4-Поместить)

Advertising Printing Full Automatic Roll To Roll CCD Alignment Silk Screen Printing Machine Application:

This machine is widely used in flexible circuit board FPC/PET/PVC, Ключи мобильного телефона, 3M adhesive, Мембранные переключатели, photovoltaic engergy, Бумага для перевода (фильм), Пленка для теплого пола, Геотермальная пленка, electro thermal film, цветная бумага, фильм, Заводская табличка, film switch, trademark laser, scratch cards, Самоклеящиеся наклейки, бумага, лента, aluminum foil and copper foil roll material silk screen printing.

Automatic Roll To Roll CCD Alignment Silk Screen Printing Machine Procedure

Raw material →Automatic feeding machine (anti-dusting, removing film, electrostatic eliminating)→Automatic printing ( automatic punching, печатание, QC, automatic feeding )→Automatic oven (be self-polishing , protective film, attach tape, release paper ) →Automatic receiving →Automatic punching machine( cut)→End product.

Feeding Machine —–Размотчик

Air shaft for the roll unwinding with tension control.

Air shaft for protective film peel off.

Dust cleaning rollers for film cleaning.

Splicer with cutting guide slot for easy film connection.

Static eliminator—-Ionizing Air Blower.

Automatic stop and alarm when the film run out.

Corrector

The EPC automatic correction system is adopted to effectively ensure the straightness of the material during transportation.

Improve the alignment speed of the CCD vision system.

Ensure the neatness of the material during the collection, which is a good foundation for the next process.

CCD Printing Table & Printing Head

Вакуумный стол с всасыванием воздуха в процессе печати. CCD vision alignment, printing table automatic rotate to positioning. 3 датчики для автоматической регистрации по осям X-Y.

Frame and printing head up-down by pneumatic.

Горизонтальное перемещение печатающей головки с помощью серводвигателя.

Высокоточные рельсы и подшипники для ходовых частей. Конструкция без подтекания ракеля

Touch Screen Operation

User-friendly PLC control combined with touch screen monitor for maximum operational convenience.

The default language is Chinese-English, customer can convert to use, we also accept other language customization.

The touch screen is used to control the lifting of the printing head to facilitate the maintenance, loading, unloading and cleaning for the screen and scraper.

CCD Registration System

Printing is performed automatically via CCD positioning and the CCD field of view is adjustable as per material dimension.

CCD automatically calculates the spatial positions of the material and the screen according to the Mark points on the material and then commands X, Y and θ of the motor motion control and adjusting platform to rotate for automatic positioning printing.

Quality Inspection Glass Table

Glass table for printing quality inspection.

Touch screen control panel in English language.

Automatic reminding when operation error occur.

Panasonic PLC for machine control.

Machine software can be upgraded for longlife.

Hot Air Dryer—-Перемотчик

Chamber film pass length 60 meters.

Heating range from room temperature to 200°C.

Insulation layer to keep heat inside the chamber.

6 fans for cured film cooling.

3 inch dia. air shaft to rewind the cured film into a roll.

Laminator can be added on the dryer.

Adopt numerical control motor, printing and ink return speed, distance can be set by sections at will.

The brush adopts Panasonic servo motor and linear guide rail, which is fast, stable and precise;

Преимущества Vility

1.Печатание, штамповка, Точность высечки 0,02 мм. Система визуального выравнивания ПЗС-камер, Быстрое и точное позиционирование и тонкая настройка, для обеспечения требований к точности.

2.We provide CAD and 3D design sketches. We perform three phases of QC to ensure product quality.

3.Мы всегда следовали правилам стандартизации для строгого производственного процесса, Экономия времени и средств для обеих сторон и получение максимальной выгоды для вас.

4.Принять OEM / ODM, Настройка всей линии трафаретной печати.

Vility provide quality products and perfect engineering service:

1.10 years professional production experience in printing punching machinery industry.

2.5000 m^2 production workshop, strong production capacity.

3.Professional senior engineer develop the best solution.

4.Strict quality control system, CE certificate available.

5.Main components adopt imported international famous brand.

6.Timely delivery, half of an hour to shenzhen port.

7.Professional after-sale service, Email will be reply in 24 hours.

8.Site installation or video support and commissioning in your factory

9.We got many machine development patents, software system can be upgrated by free in lifelong.

10.Все наши машины могут иметь годовую гарантию и пожизненное обслуживание.

11.Giving a free technical training for your employees.

VILITY Printing Machine, Your reliable and dependable supplier in China

1/ 24-hours Consultation Service, Product, Решение, After-sale.

2/Technical Support: Online Engineer, Professional customer service, Technical sales forces.

3/ Запчасти: some are for free, all will be discounted.

4/ Oversea engineer available. Online maintenance support worldwide

Q:Is it possible for you to assign engineers to our company?

A:yes. Our engineers can go to your company for on-site service. Однако, you need to pay the corresponding fee.

Q:Предоставляете ли вы услуги по установке и обучению??

A:Да, Мы предоставим вам профессиональные руководства по установке и обучению, а также видеоуроки. Кроме того, будут организованы видеопереговоры в режиме реального времени, которые помогут вам в ходе операции.

Q:Какой гарантийный срок на ваше оборудование?

A:Мы даем гарантию на всю машину в течение одного года и предоставляем пожизненную услугу по обновлению программного обеспечения.

Wooden Package with film protector wrap around all machine units

The screen printing machine and all spare parts will be packed compact strictly to assure its safety. All equipment will be kept in good conditions when come to your side although a long distance transportation.

Трафаретная печатная машина Путь доставки

Трафаретная печатная машина

Трафаретная печатная машина